Oil distribution tank for replacing air conditioner refrigerant and system applying oil distribution tank

A refrigerant and oil tank technology, applied in the system field, can solve the problems of refrigerant waste, unfavorable refrigerant environment, physical health damage, etc., and achieve the effects of eliminating leakage and waste, maintaining working environment, and simple structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

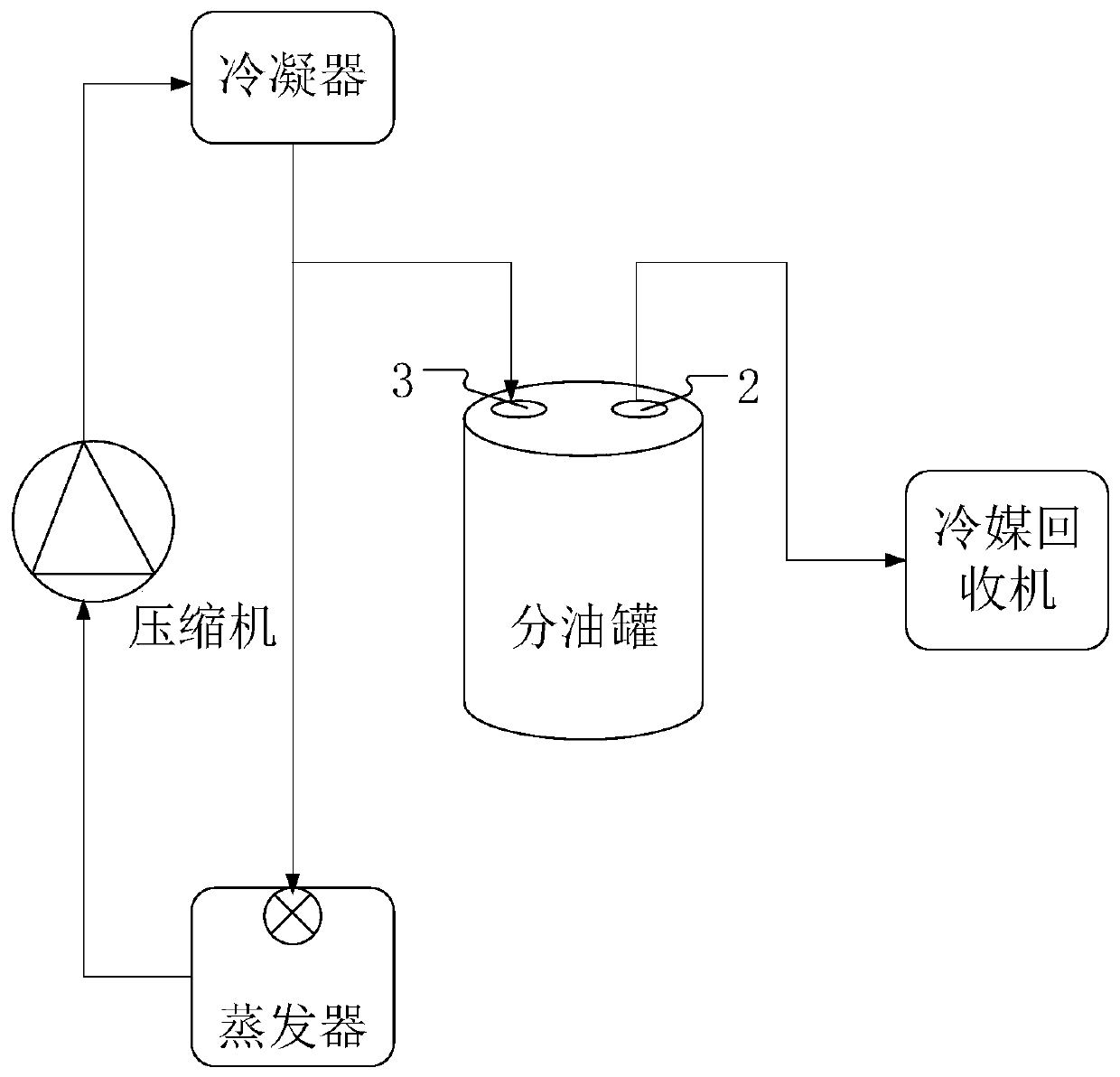

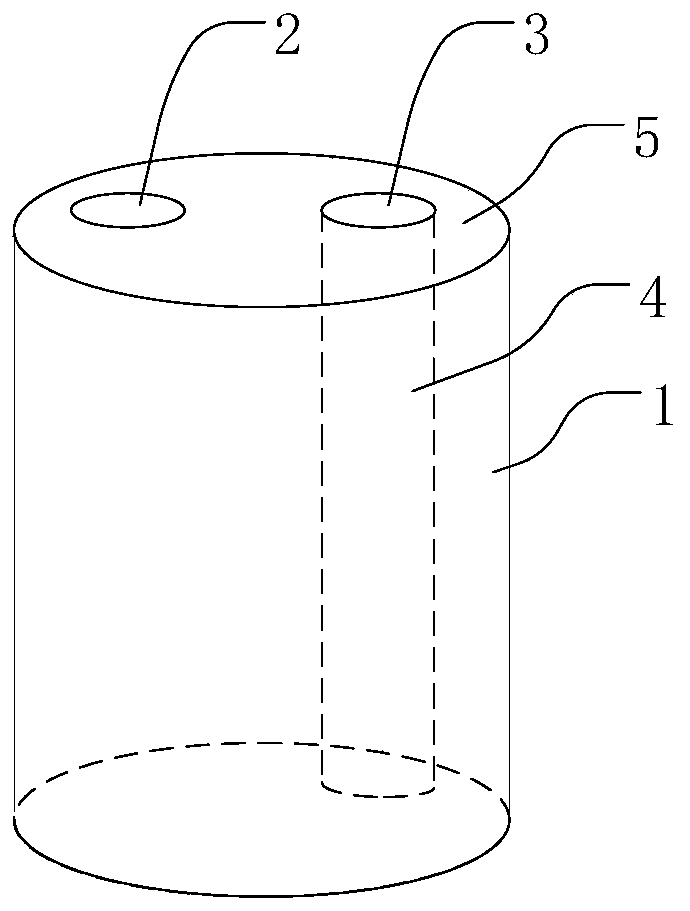

[0036] The invention relates to an oil separation tank for replacing air-conditioning refrigerant, comprising a tank body 1, a refrigerant outlet 2 arranged on the top of the tank body 1, and a refrigerant inlet 3 arranged on the tank body 1; 1 communicates with a conduit 4 leading into the bottom of the tank body 1 . The refrigerant inlet 3 is arranged on the top of the tank body 1 on the same side as the refrigerant outlet 2 , and the conduit 4 is a straight pipe connecting the refrigerant inlet 3 to the bottom of the tank body 1 .

[0037] Optionally, the tank body 1 is made of a transparent material, so that the recovery ratio of the refrigerated oil can be checked at any time, and the refrigerated oil can be poured back into the system before the refrigerated oil is full. Both the refrigerant inlet 3 and the refrigerant outlet 2 are provided with sealing gaskets to prevent the refrigerant from leaking at the refrigerant inlet 3 and the refrigerant outlet 2 . The side of ...

Embodiment 2

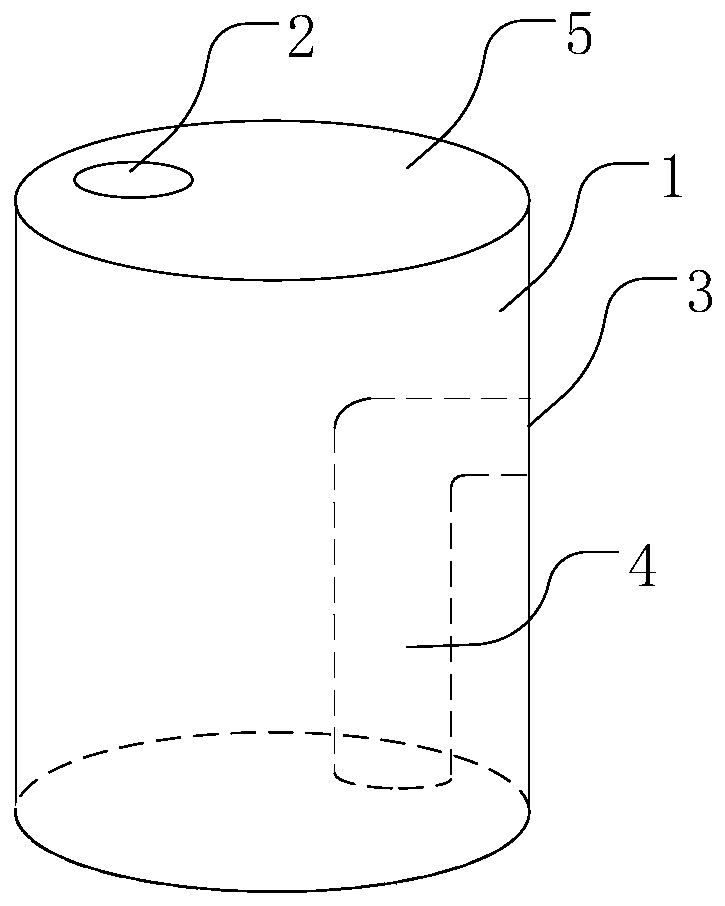

[0041] The difference between this embodiment and the first embodiment is that the refrigerant inlet 3 in this embodiment is arranged on the side wall of the tank body 1 , and the conduit 4 is an elbow connecting the refrigerant inlet 3 to the bottom of the tank body 1 .

Embodiment 3

[0043] The difference between this embodiment and the second embodiment is that the conduit 4 in this embodiment is a straight pipe arranged obliquely, connecting the refrigerant inlet 3 to the bottom of the tank body 1

[0044] The invention eliminates the leakage and waste of the refrigerant through the simple structure design of the oil separation tank, maintains a healthy working environment, and reduces the environmental pollution caused by the leakage of the refrigerant; the cost of the refrigerant is reduced by at least 10,000 yuan per year; It takes half an hour for natural leakage, and the recovery time is 5-8 minutes by using the oil separation tank, which improves the efficiency by at least 80%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap