A method of forced moulting to improve the production performance of meat breeding ducks

A technology of forced moulting and production performance, which is applied in animal husbandry and other fields, can solve the problems of low fertilization rate and high death rate, and achieve the effects of reducing death rate, avoiding injury and improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

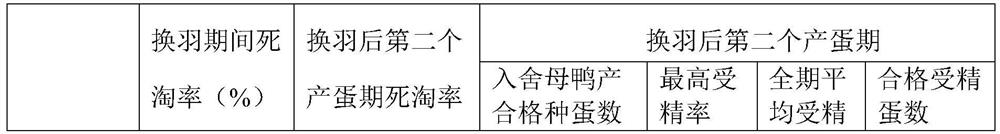

Examples

Embodiment 1

[0028] A method of forced molt to improve the production performance of meat breed ducks. The total number of meat breed ducks is 5000, including 915 male ducks and 4085 female ducks. The specific method is as follows:

[0029] (1) Preparation before forced moulting: Eliminate all overweight, underweight and disabled breeding ducks 7 days before feed cut-off, so as to reduce the death rate during forced moulting and reduce economic losses. Renovate and strengthen the partitions in the house to prevent breeding ducks from crossing fences, overhaul drinking water facilities and lighting fixtures, and replace damaged light bulbs. Select the male ducks 3 days before the cut-off, place them in No. 9-10 pens and confirm the quantity, and evenly divide the female ducks into No. 1-8 pens and count the quantity. 1 day before the feed is cut off, remove all the feeding boxes and egg-laying boxes in the house, thoroughly clean the duck manure, duck feathers, dust and spider webs in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com