Aluminum plate processing device and processing method

A processing device and aluminum plate technology, applied in the direction of shearing device, metal processing equipment, manufacturing tools, etc., can solve the problems of continuous production and processing, waste of manpower and material resources, etc., to improve the shearing effect, improve accuracy, and improve leveling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

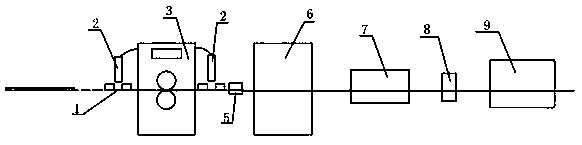

[0044] like figure 1 and figure 2 As shown, the aluminum plate processing device includes:

[0045] The carrying platform 1 is used to carry the aluminum plate through various processes for processing in sequence;

[0046] Leveler 3, used to level the aluminum plate;

[0047] Edge trimming device 5 is used for edge trimming of the aluminum plate;

[0048] The cleaning device 6 is used to clean the surface of the aluminum plate;

[0049] The surface treatment device 7 is used to treat the surface of the aluminum plate;

[0050] Transverse shearing device 8, used for transversely cutting the aluminum plate;

[0051] The slitting device 9 is used for longitudinally cutting the aluminum plate;

[0052] The carrying platform 1 carries the aluminum plate through the leveler 3, the trimming device 5, the cleaning device 6, the surface treatment device 7, the transverse shearing device 8 and the longitudinal shearing device 9;

[0053] It also includes a detection device 2, a ...

Embodiment 2

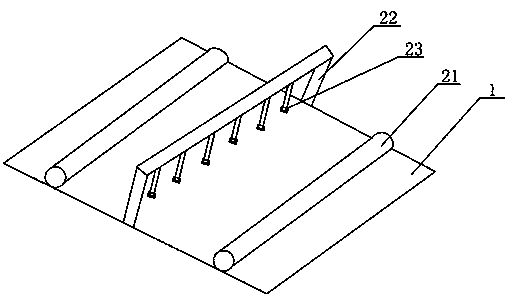

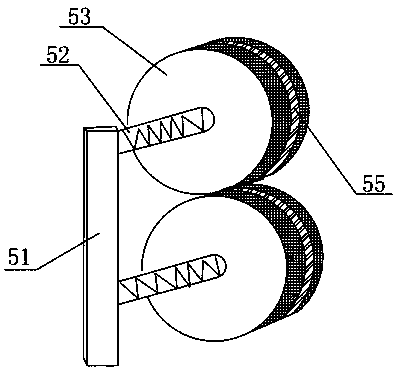

[0056] like figure 1 and image 3 As shown, for embodiment 1, the edge trimming device is optimized in this embodiment.

[0057] The trimming device 5 comprises a second fixing part 51, a first screw rod 52, a trimming roller 53 and a trimming tool 55, and the carrying platform 1 both sides are provided with a second fixing part 51, and two fixing parts 51 are fixed on the second fixing part 51. The first screw 52, the other end of the first screw 52 is rotatably connected with a trimming roller 53, the surface of the trimming roller 53 is provided with an annular trimming tool 55, and the trimming roller 53 clamps and cuts the aluminum plate carried by the carrying platform 1 . The edge trimming tool 55 can be made up of cemented carbide material, and its hardness will be much higher than the hardness of the cut aluminum plate, and the edge trimming tool 55 can be welded on the roller surface of the edge trimming roller 53; Cutter installation groove, trimming cutter 55 ...

Embodiment 3

[0061] like figure 1 and Figure 4 As shown, for the above-mentioned embodiments, this embodiment optimizes the cleaning device.

[0062] The cleaning device 6 comprises a cleaning device body 61, a first spray gun 62, a second spray gun 63, a heating net 64 and a first dividing plate 65, and the carrying platform 1 runs through the cleaning device body 61, and the cleaning device body 61 is divided into upper, upper, and lower parts. In the lower part, the cleaning device body 61 is provided with a first partition 65, which divides the cleaning device body 61 into a cleaning cavity and a drying cavity, and the first partition 65 is provided with a through hole for passing through the carrying platform 1 , the upper and lower parts in the cleaning chamber are respectively provided with a number of first spray guns 62 and second spray guns 63, the first spray guns 62 and the second spray guns 63 are ejected towards the plane of the carrier platform 1, and the upper and lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com