Control flow homogenization silo and discharging method thereof

A technology to homogenize the warehouse and control the flow. It is applied in the directions of loading/unloading, transportation and packaging, which can solve the problems of energy waste and high floor height of the warehouse, and achieve the effect of reducing equipment investment, reducing production power consumption and reducing the length of the chute.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

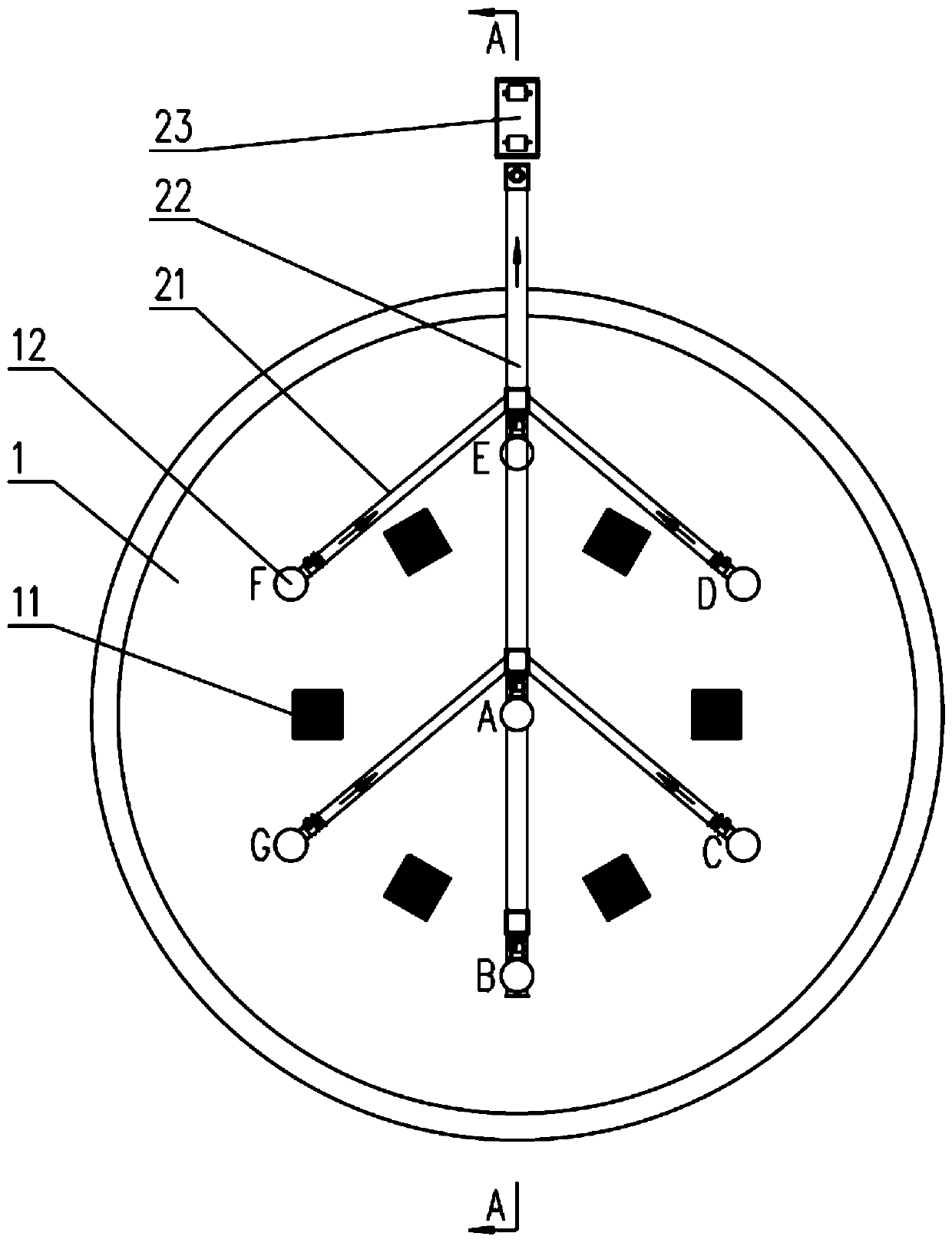

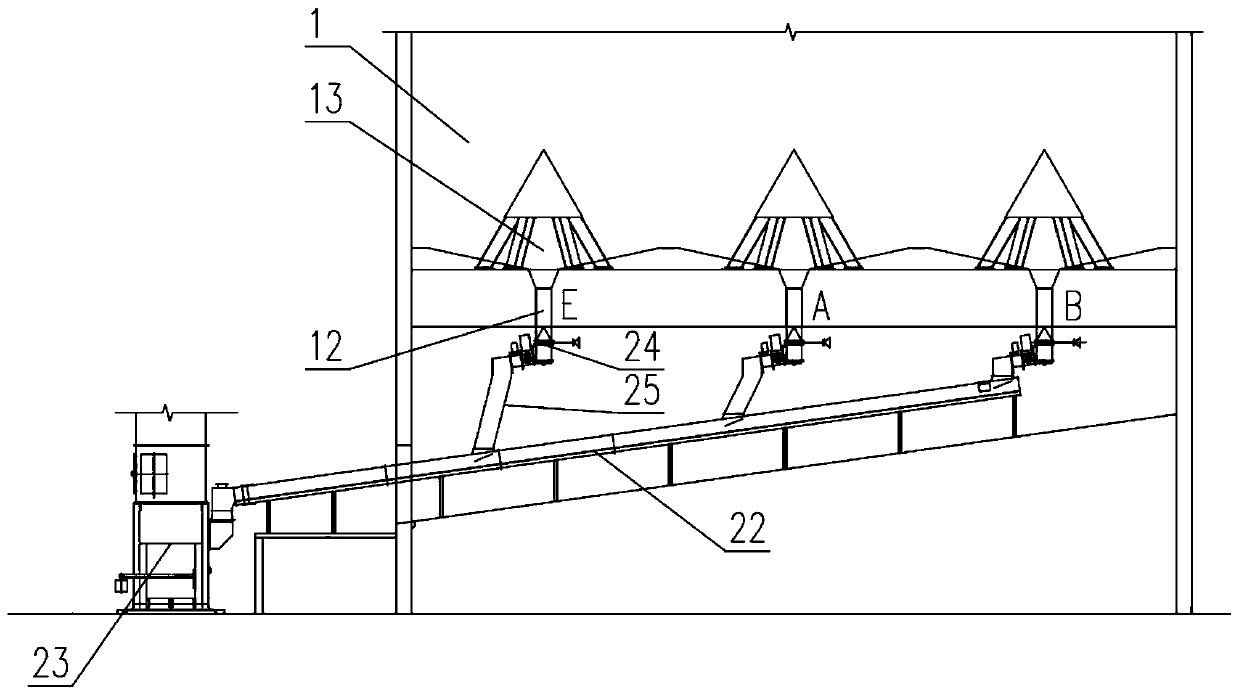

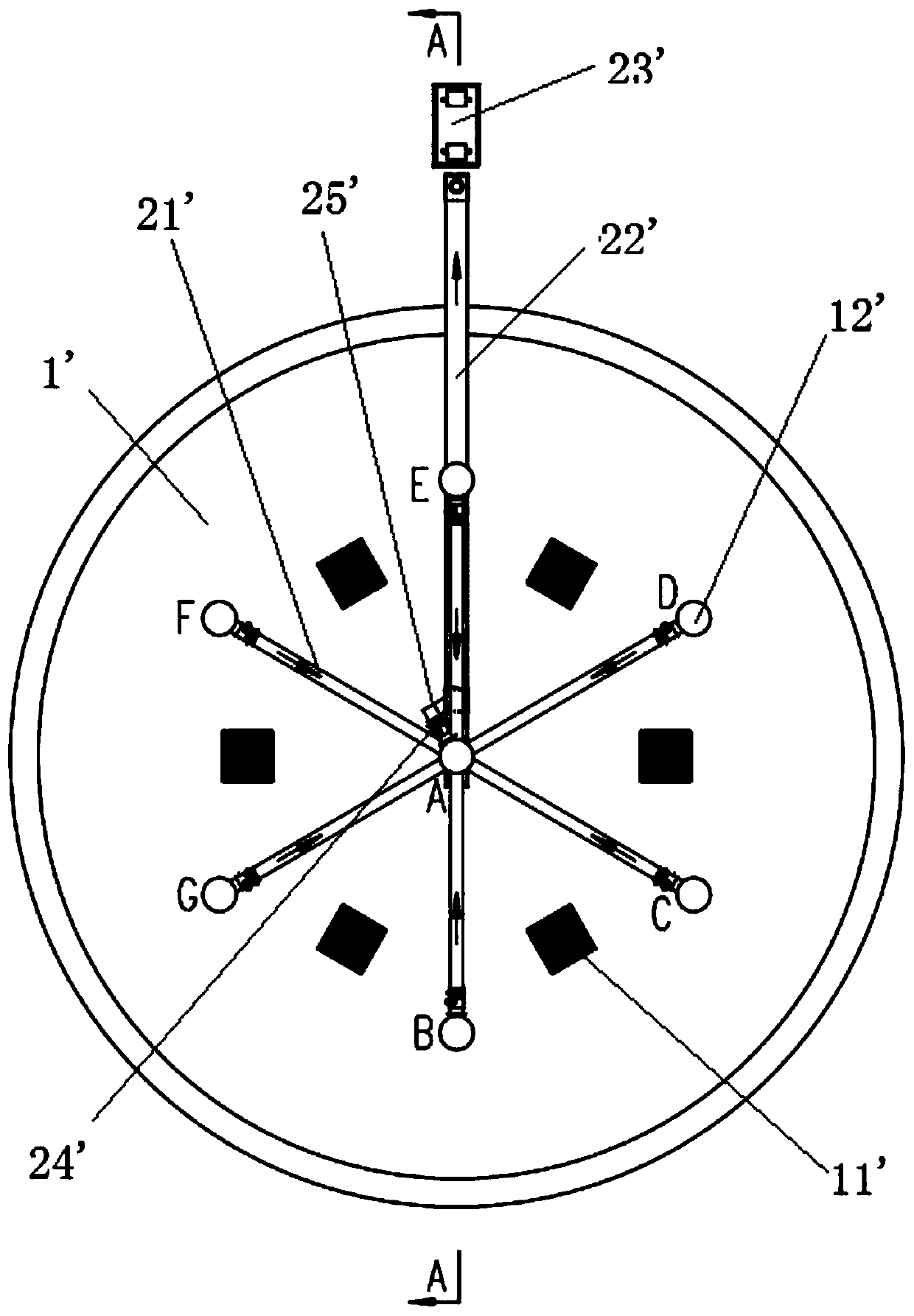

[0031] In order to avoid ineffective transportation of materials in the control flow homogenization storehouse and effectively save costs, the present invention arranges a main air conveying chute just below the unloading areas A, B, and E of the control flow homogenization storehouse. The material is directly fed into the main air conveying chute through the chute, and the raw material discharged from the C, D, F, G unloading areas is conveyed to the main air conveying chute by the four secondary air conveying chutes, and the four secondary air conveying chutes make the four secondary air conveying chutes The lower inclined end of the conveying chute is arranged biased towards the direction of the bucket elevator. Since the conveying direction of the raw meal in the secondary air conveying chute and the conveying direction of the raw meal in the main air conveying chute are both towards the direction of the bucket elevator, it can avoid the ineffective conveying of the raw mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com