rolling bearing

A technology of rolling bearings and rolling elements, applied in the field of rolling bearings, can solve problems such as reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below, identical or functionally equivalent elements are represented by the same drawing marks.

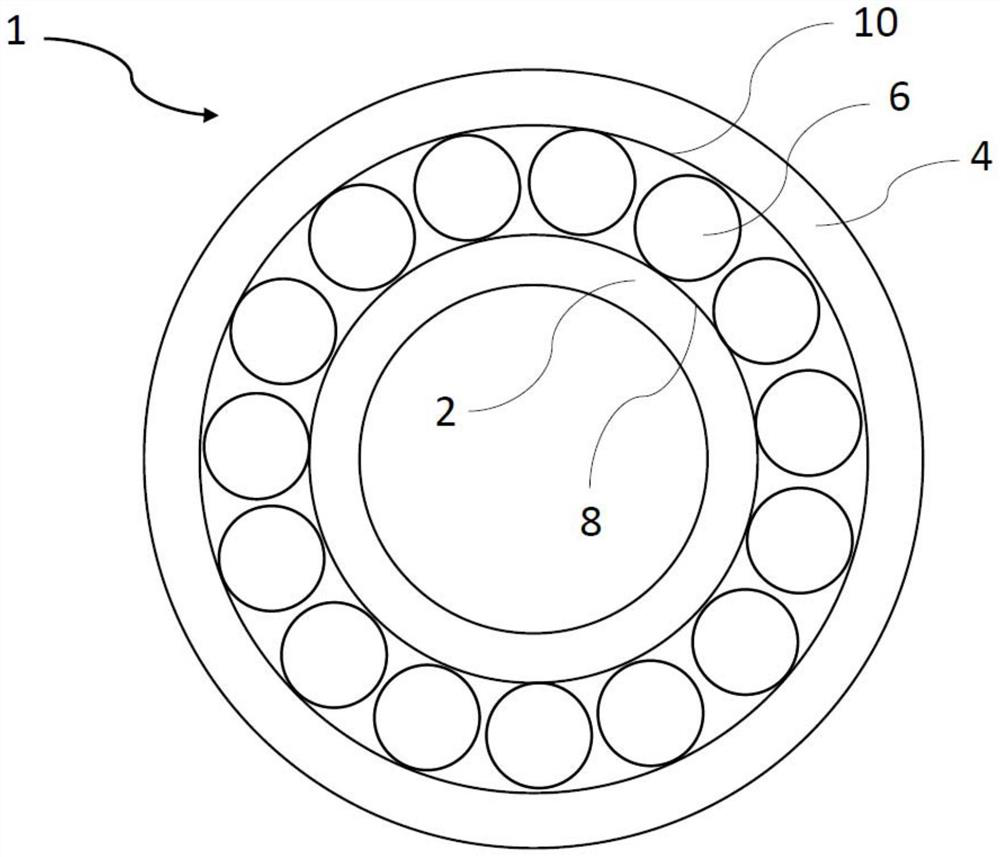

[0043] at Figure 1, the rolling bearing 1 is drawn in a very simplified profile. Rolling bearings 1 consist of an inner ring 2 and an outer ring 4. The rolling element 6 may be arranged rotatably between these two circles 2 and 4. Here, the rolling element 6 runs against the outer surface 8 of the inner ring 2 and the inner surface 10 of the outer ring 4 (run). In order to protect raceways 8, 10 and rolling elements 6 from wear, these (constituent parts) are each provided with a coating. Here, the coating of the rolling element 6 may have a greater hardness than the coating of raceway 8, 10. The coating of the rolling element 6 may, for example, be baked blue (bluing).

[0044] Circle raceways 8, 10 (preferably the entire circle 2, 4) is provided with a phosphate coating (phosphate coating), in order to provide a sliding layer for rolling elements 6. In particular, the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com