Epoxy zinc-rich primer

An epoxy zinc-rich primer and epoxy resin technology, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of weakened anti-rust effect of zinc powder, brittle anti-crack expansion ability, easy cracking and other problems , to achieve the effect of improving protection, reducing cracking and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The preparation process of the toughened modified epoxy resin specifically includes the following process steps:

[0089] S1: Preparation of acrylate oligomers, specifically adding acrylic monomers into n-butanol solvent in proportion, heating to 100°C in a water bath under the protection of nitrogen, and reacting for 2.5 hours to obtain acrylate oligomers;

[0090] S2: Epoxy resin modification, specifically mixing the epoxy resin and the acrylate oligomer obtained in step S1 in proportion, adding DMP-30 accelerator and reacting at 100°C for 1 hour to obtain the toughened modified ring oxygen resin.

[0091] Additives in component A include the following components by weight percentage:

[0092] Organic bentonite 20%;

[0093] Auxiliary 10%;

[0094] Anti-rust material 35%;

[0095] Filler 35%.

[0096] Among them, organic bentonite is produced by Tianlong Organic Soil Bentonite Co., Ltd.

[0097] Auxiliary agent then comprises the component of following weight pe...

Embodiment 1

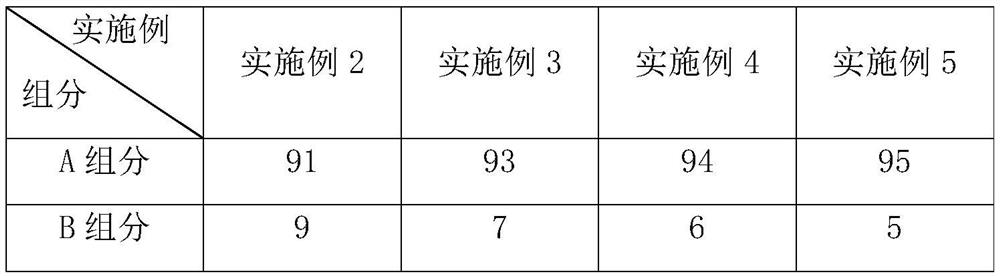

[0126] The difference between embodiments 15-18 and embodiment 1 is that the weight percentage of each component in the toughened modified resin is calculated as the following table:

[0127]

[0128] The difference between embodiment 19-20 and embodiment 1 is that the weight percent of each component in the acrylate oligomer is calculated as the following table:

[0129]

[0130] The difference between Embodiment 21-26 and Embodiment 1 is that the weight percent of each component in the acrylic monomer is calculated as the following table:

[0131]

[0132] The difference between Examples 27-30 and Example 1 is that in the preparation process of the toughened modified epoxy resin, each parameter is calculated as the following table:

[0133]

[0134]

[0135] The difference between embodiments 31-37 and embodiment 1 is that the weight percent of each component in the additive is calculated as the following table:

[0136]

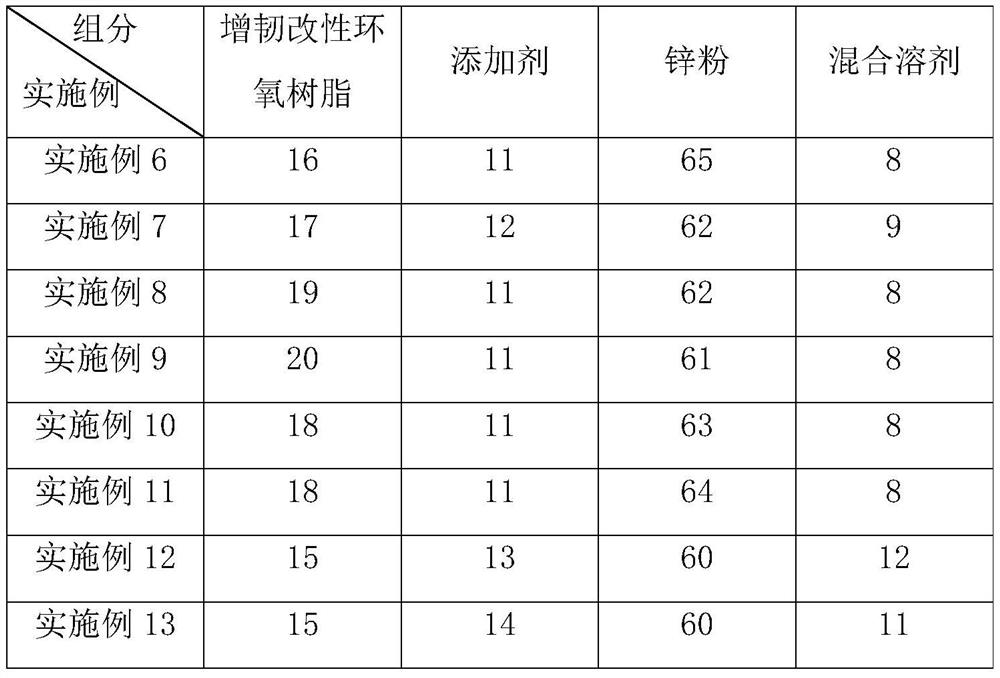

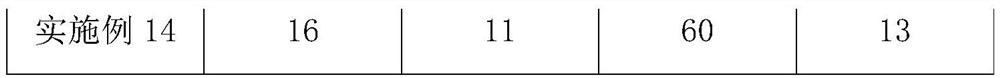

[0137] The difference between embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com