High-performance bulletproof garment

A high-performance technology for body armor, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of heavy weight, short life, and complex structure of body armor, and achieve improved bulletproof performance, long life, and good protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

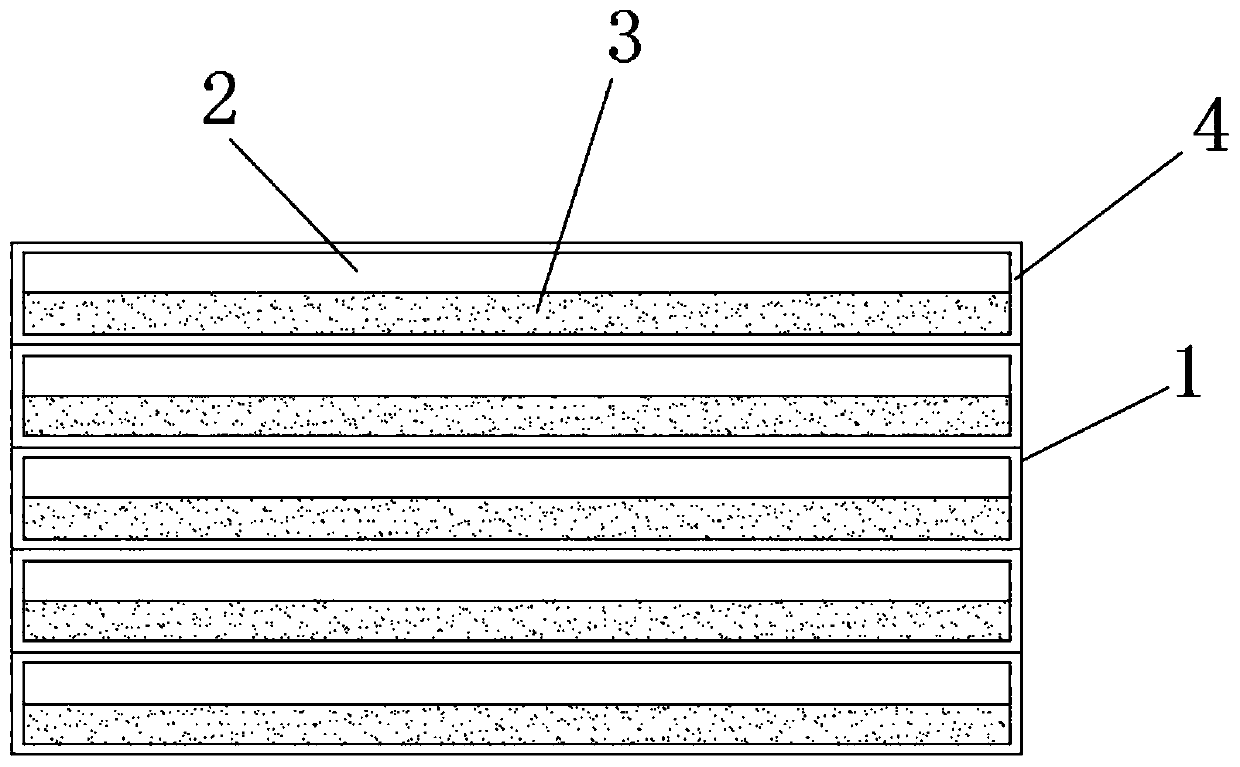

[0025] The invention discloses a high-performance body armor, which comprises a body armor body, the body armor body is filled with a body armor layer, and the body armor layer is composed of a polyurethane film layer and an ultra-high molecular weight polyethylene fiber cloth layer. The polyurethane film layer is located on the upper part of the ultra-high molecular weight polyethylene fiber cloth layer, and the polyurethane film layer and the ultra-high molecular weight polyethylene fiber cloth layer are connected to each other by a hot pressing process.

[0026] Further, the ultra-high molecular weight polyethylene fiber cloth layer is composed of an ultra-thin adhesive film made of water-based polyurethane resin and polyethylene fibers, and the ultra-thin adhesive film accounts for 20% by mass of the polyethylene fiber.

[0027] Further, the hot pressing temperature of the polyurethane film layer and the ultra-high molecular weight polyethylene fiber cloth layer is 130 degr...

Embodiment 2

[0038] The invention discloses a high-performance body armor, which comprises a body armor body, the body armor body is filled with a body armor layer, and the body armor layer is composed of a polyurethane film layer and an ultra-high molecular weight polyethylene fiber cloth layer. The polyurethane film layer is located on the upper part of the ultra-high molecular weight polyethylene fiber cloth layer, and the polyurethane film layer and the ultra-high molecular weight polyethylene fiber cloth layer are connected to each other by a hot pressing process.

[0039] Further, the ultra-high molecular weight polyethylene fiber cloth layer is composed of an ultra-thin adhesive film made of water-based polyurethane resin and polyethylene fibers, and the ultra-thin adhesive film accounts for 23% by mass of the polyethylene fiber.

[0040] Further, the hot pressing temperature of the polyurethane film layer and the ultra-high molecular weight polyethylene fiber cloth layer is 133 degr...

Embodiment 3

[0051] The invention discloses a high-performance body armor, which comprises a body armor body, the body armor body is filled with a body armor layer, and the body armor layer is composed of a polyurethane film layer and an ultra-high molecular weight polyethylene fiber cloth layer. The polyurethane film layer is located on the upper part of the ultra-high molecular weight polyethylene fiber cloth layer, and the polyurethane film layer and the ultra-high molecular weight polyethylene fiber cloth layer are connected to each other by a hot pressing process.

[0052] Further, the ultra-high molecular weight polyethylene fiber cloth layer is composed of an ultra-thin adhesive film made of water-based polyurethane resin and polyethylene fibers, and the ultra-thin adhesive film accounts for 25% by mass of the polyethylene fiber.

[0053] Further, the hot pressing temperature of the polyurethane film layer and the ultra-high molecular weight polyethylene fiber cloth layer is 135 degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com