Hot and spicy sauce continuous production system and method

A technology of production system and production method, which is applied in the field of food processing, can solve the problems of unsatisfactory diversified packaging, lax sealing, and inconvenient bottle filling, etc., and achieve the effects of reducing human participation, ensuring sealing quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

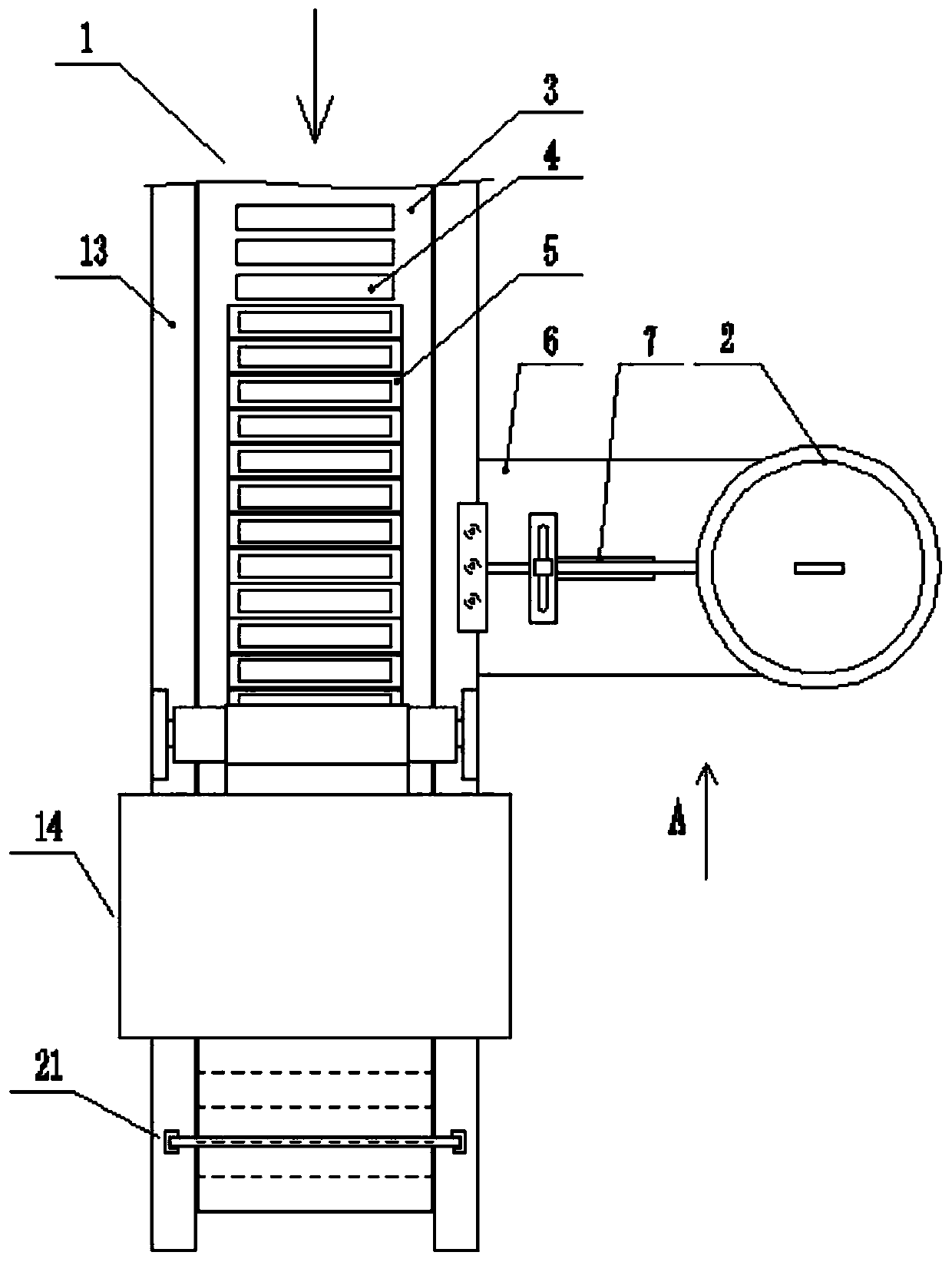

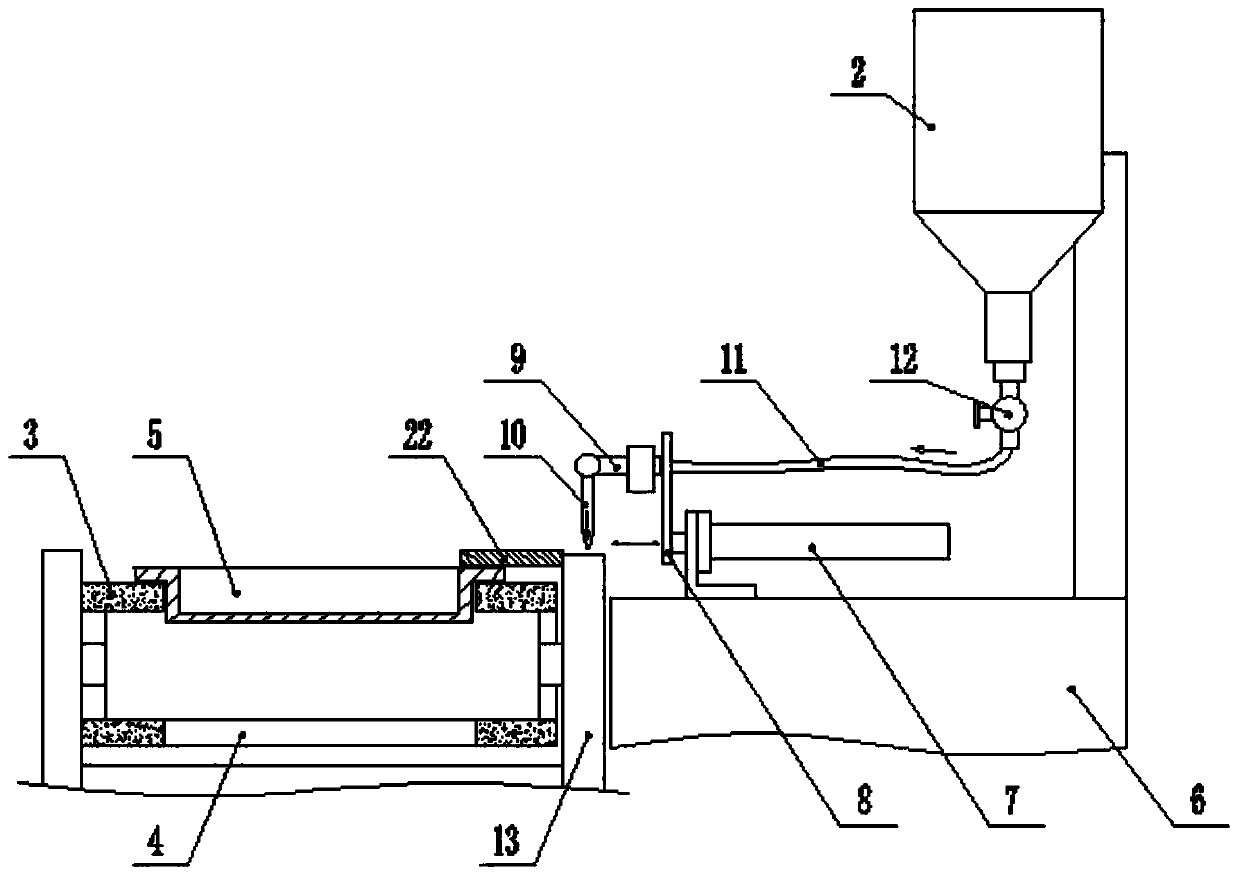

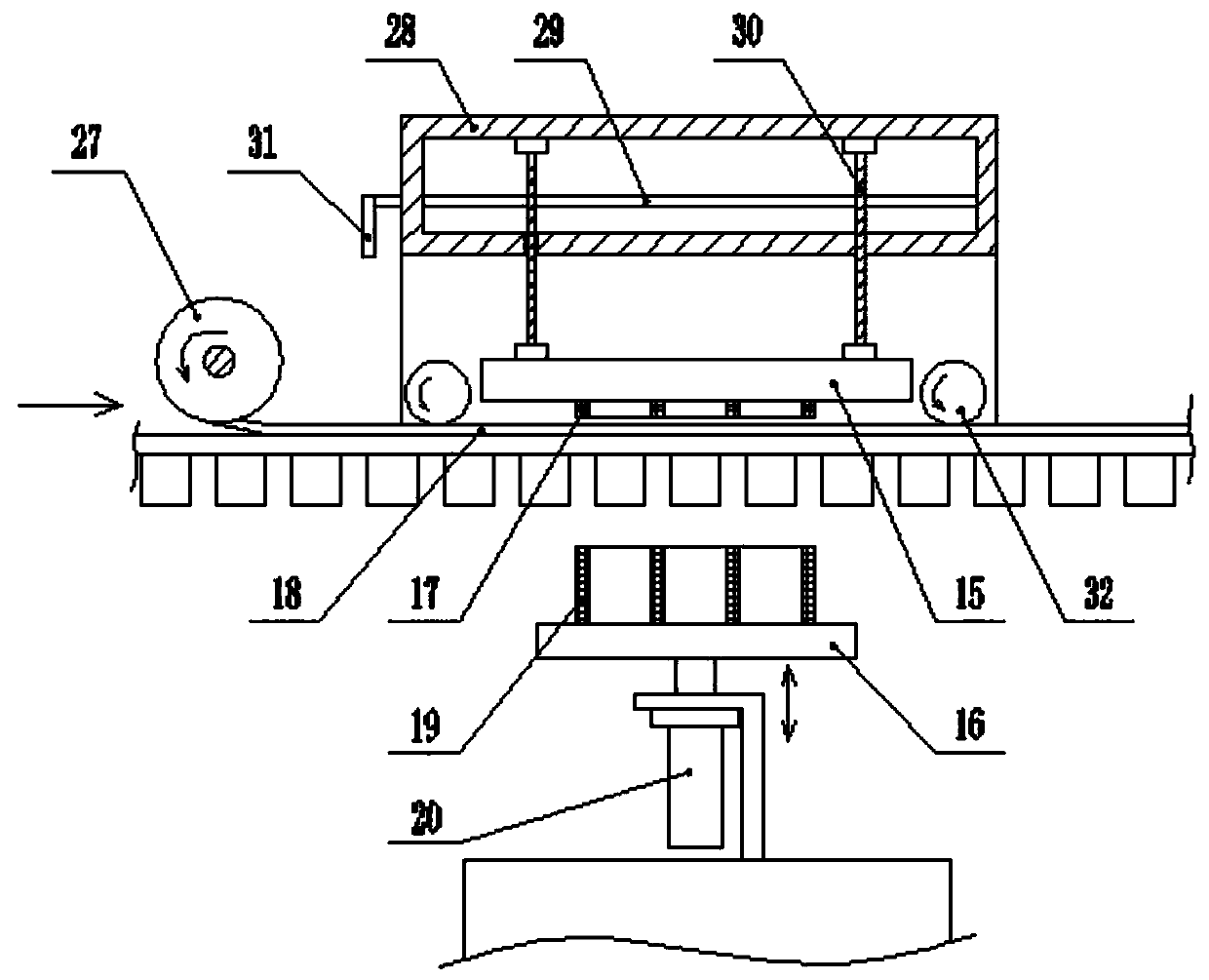

[0025] Such as Figure 1-Figure 4 Shown, the concrete structure of the present invention is: a kind of fragrant hot sauce continuous production system, and it comprises conveyor 1, material barrel 2; Described conveyor 1 preferably adopts chain conveyor, to facilitate steps such as perforation, cutting, On the chain plate of the chain plate conveyor, a storage hole 4 for placing the packaging box 5 is provided. The upper end of the packaging box 5 is open and the outer edge of the upper end is larger than the inner diameter of the storage hole 4; one side of the conveyor 1 is provided with a discharge ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap