Flat knitted bag and making method thereof

A flat knitting and knitting technology, used in weft knitting, knitting, handbags, etc., can solve the problems of difficult maintenance, cumbersome production process, limited pattern effect, etc., to maintain ecological sustainable development, enrich production methods, The effect of the production concept improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

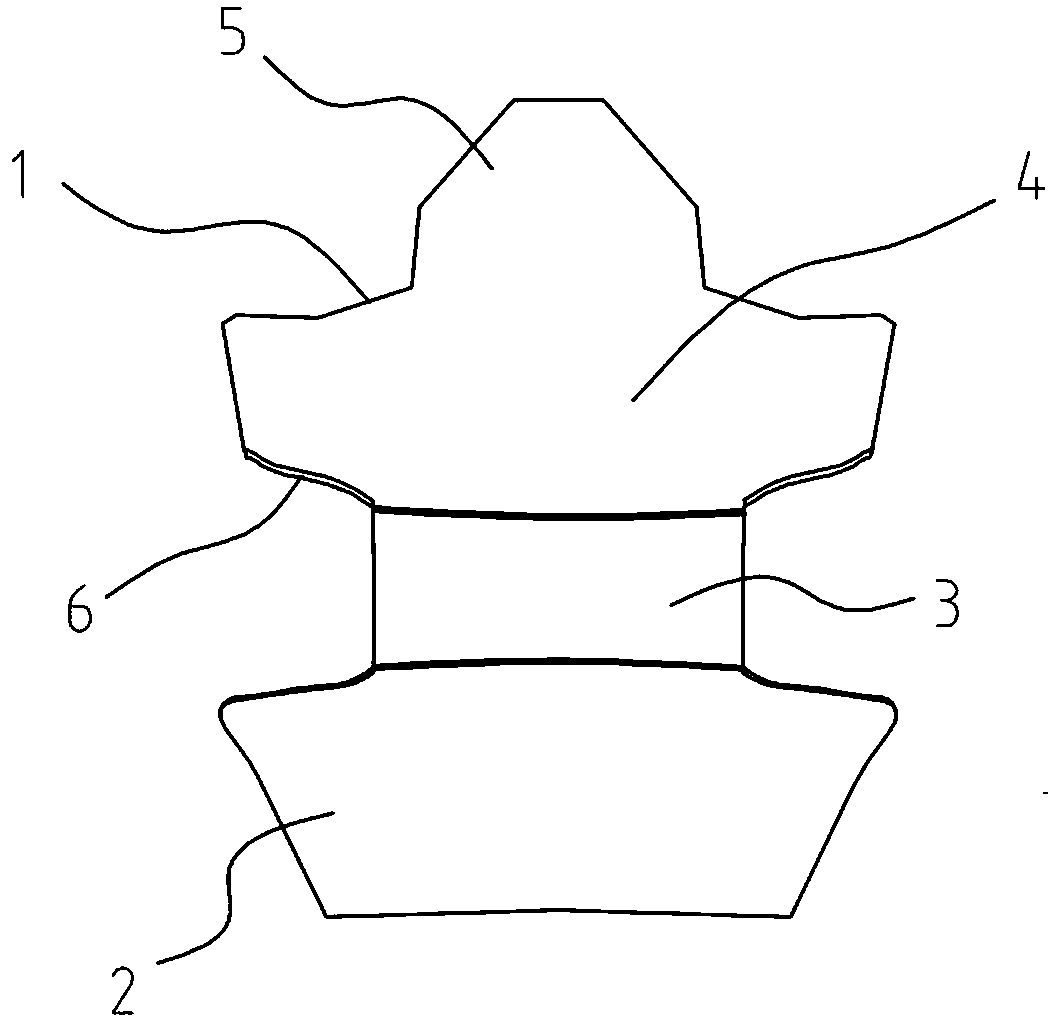

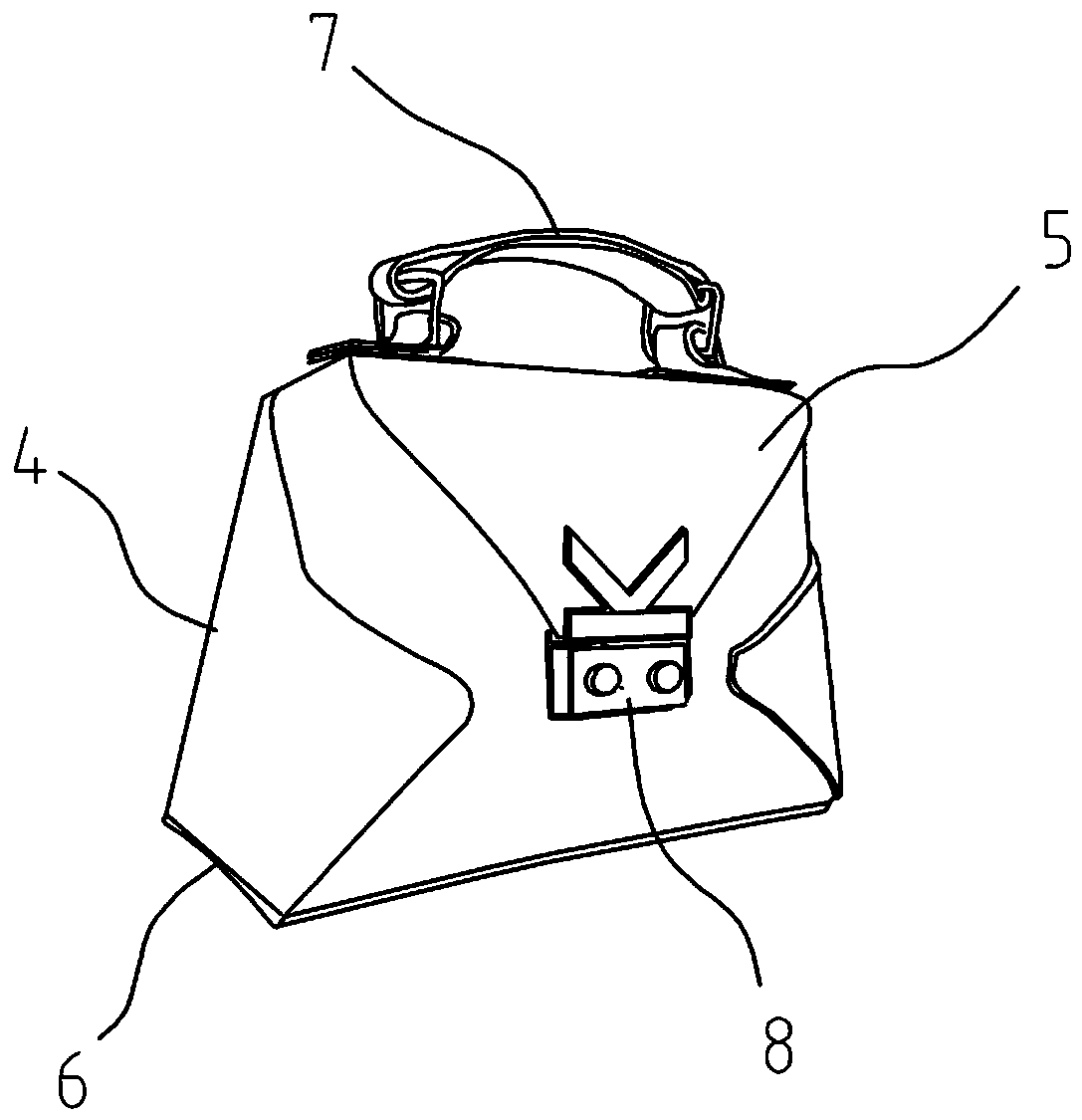

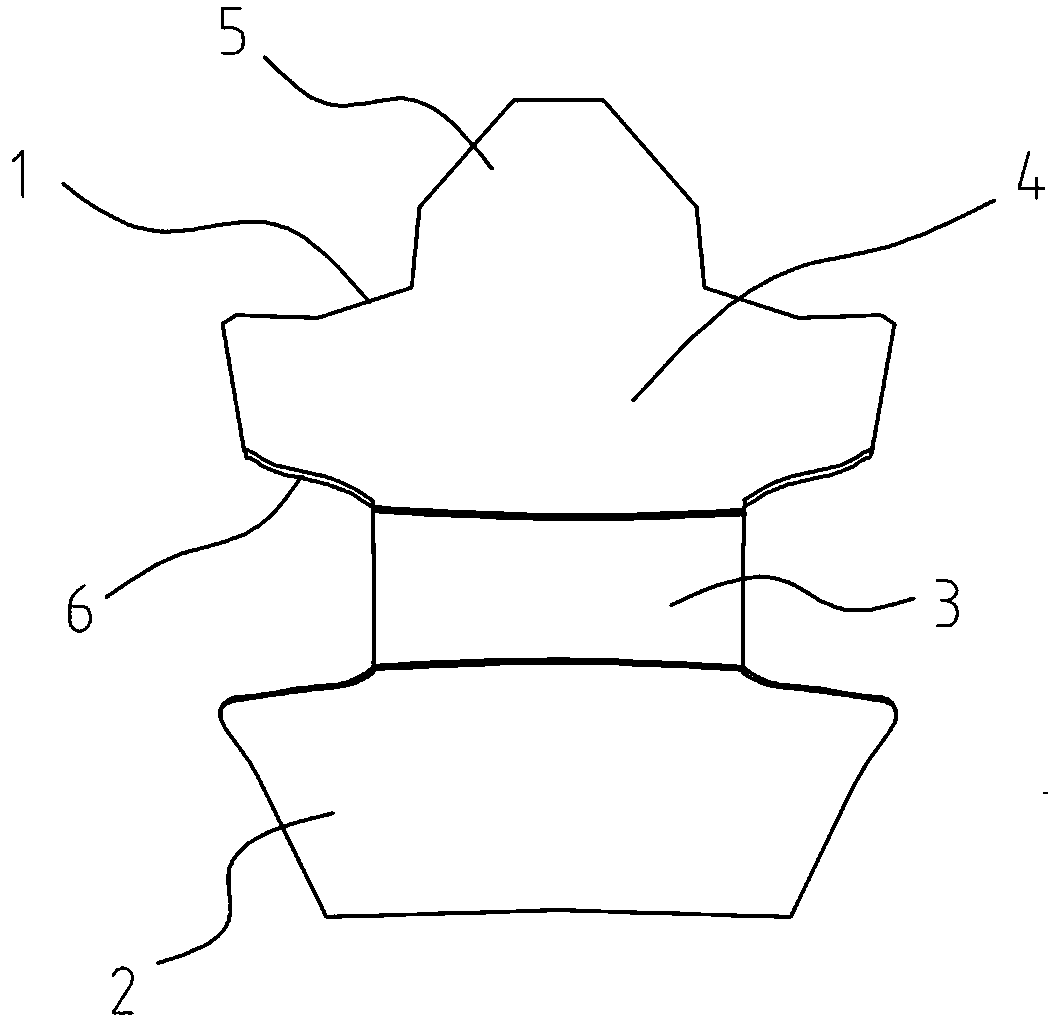

[0022] Such as Figures 1 to 2 As shown, a flat-knitted knitted bag described in this embodiment includes a body body, and the body body is composed of an outer body layer 1 and an inner body layer that are closely attached to each other, and the outer body layer 1 is One-piece or several-piece two-dimensional shaped knitted fabrics.

[0023] The main body outer layer 1 includes a wrapping front 2, a wrapping bottom 3, a wrapping back 4, and a hijab 5. The edge of the main body outer layer 1 is sewn with a wrapping 6, and the main body inner layer is a leather layer.

[0024] The flat-knitting bag also includes handles 7 and hardware components 8 .

[0025] A method for making a flat knitting bag, characterized in that the specific steps are:

[0026] (a) Determine the flat knitting yarn, determine the style composition, version size, organizational ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com