Tabletop level radio frequency microwave index screening equipment and control method thereof

A screening equipment and desktop-level technology, applied in the field of desktop-level RF microwave index screening equipment and its control, can solve problems such as low production efficiency, electrostatic damage to devices, and inability to debug and test, so as to improve production efficiency, reduce workload, and facilitate The effect of sorting and sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

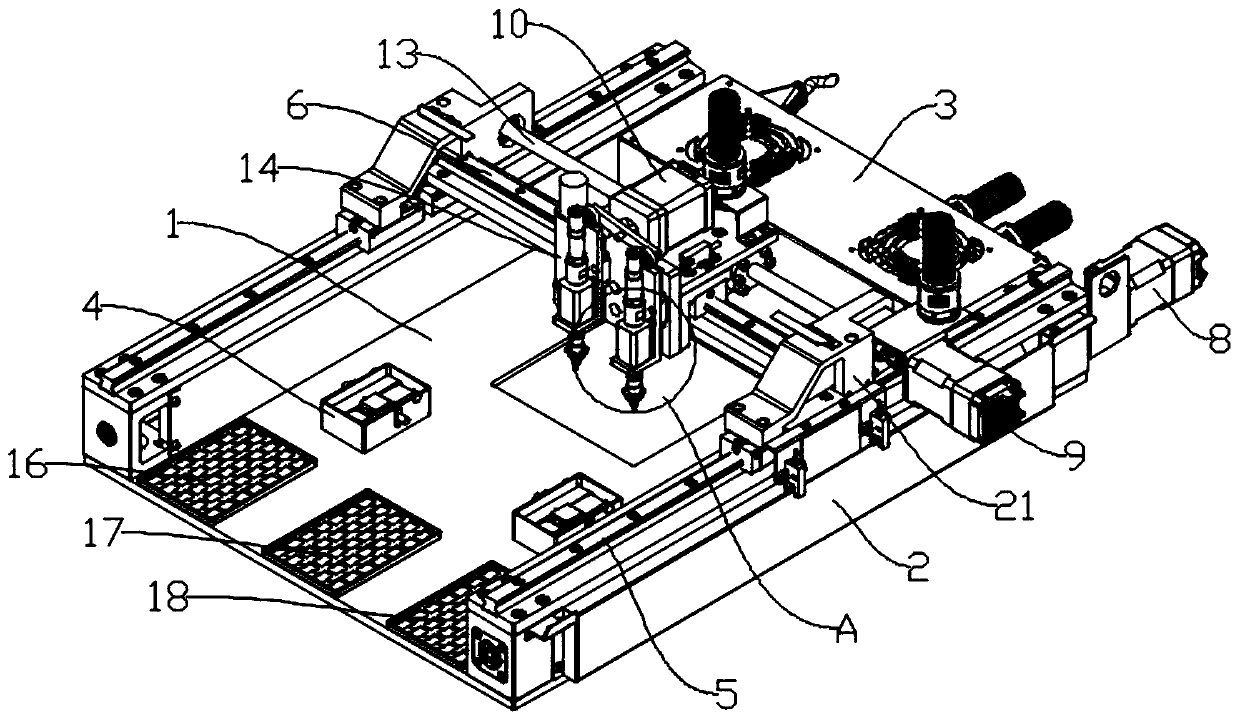

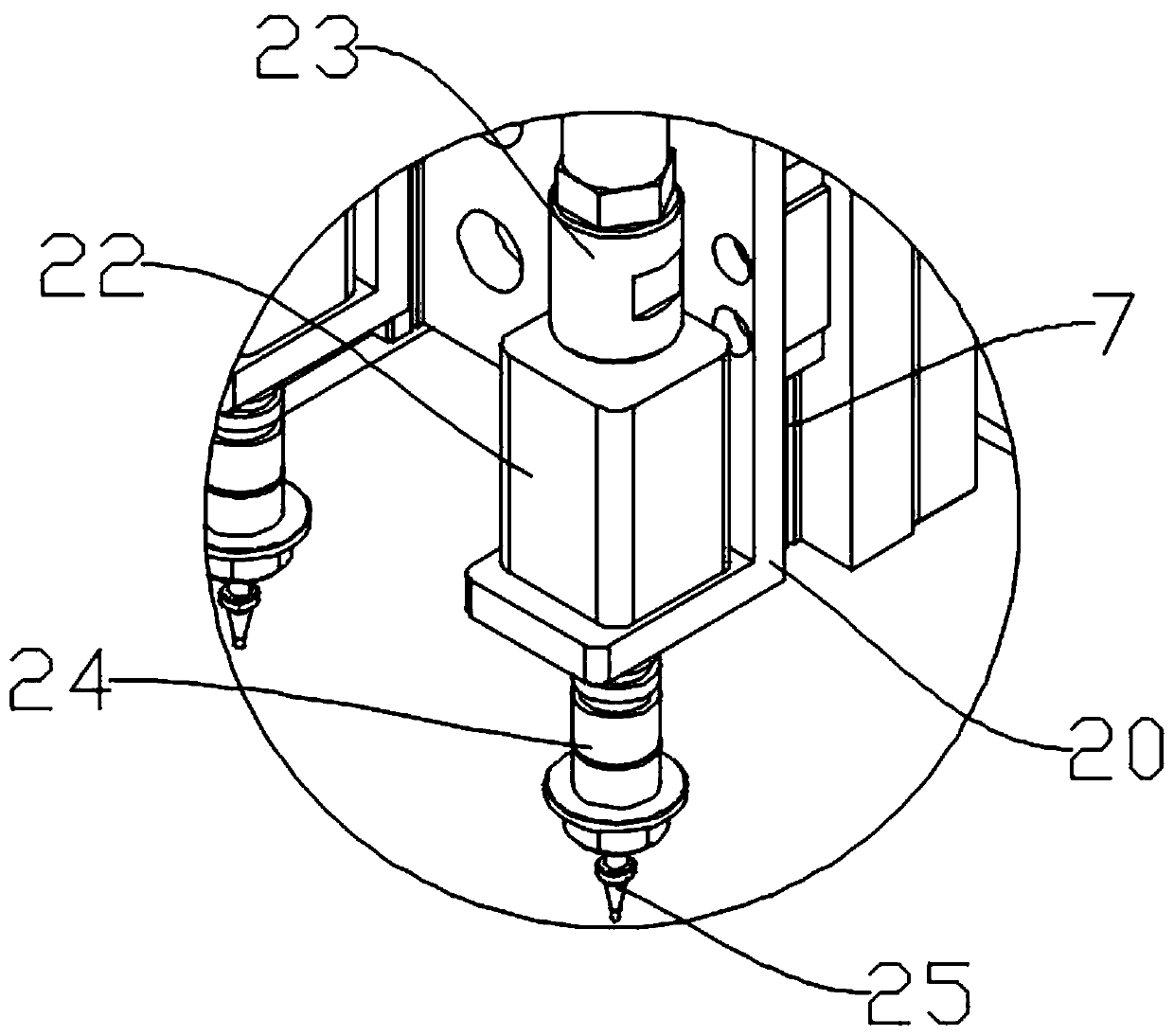

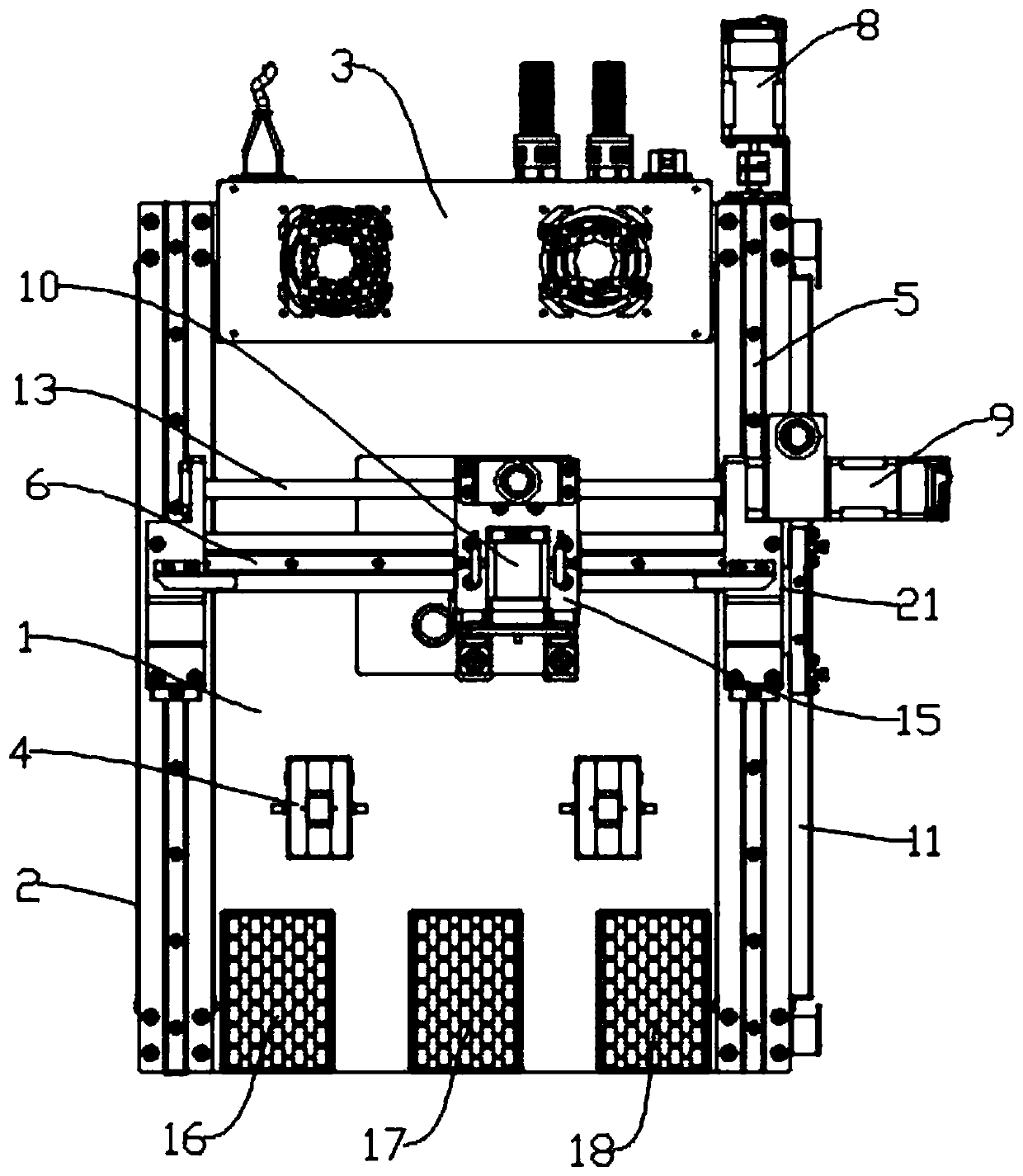

[0047] Such as Figure 1-Figure 7 As shown, a desktop-level radio frequency microwave index screening device includes a base 1, a transmission box 2 is provided on the left and right sides of the base 1, a Y-axis track 5 is provided on the top of the transmission box 2, and a Y-axis track 5 is slidably connected to a Slider 21, the inside of the transmission box 2 on the right is provided with a first screw mandrel parallel to the Y-axis track 5, the end of the first screw mandrel is connected with the output shaft of the first motor 8 arranged outside the transmission box 2 Connected by a coupling, the first motor 8 is installed on the rear side wall of the transmission box 2, and the top of the transmission box 2 is also provided with a slideway 11, the slideway 11 is as long as the Y-axis track 5, and the slide block on this side 21 is provided with connecting plate 26, and connecting plate stretches into the inside of transmission case 2 through slideway 11 and is connecte...

Embodiment 2

[0054] Such as figure 1 , image 3 and Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, the test disk includes a disk to be tested 16, an NG disk 17, and a disk 18 that has been tested. Unqualified devices are placed in the NG tray 17, and tested devices are placed in the tested tray 18, which facilitates the classification and arrangement of devices and improves production efficiency.

Embodiment 3

[0056] In this embodiment, on the basis of Embodiment 1, limit baffles are provided at both ends of the Y-axis track 5 to prevent the slider 21 from falling off from the Y-axis track 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com