Container box board forming method, device and moulding machine

A molding device and molding method technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of complicated processing, high labor cost, low processing efficiency, etc. The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

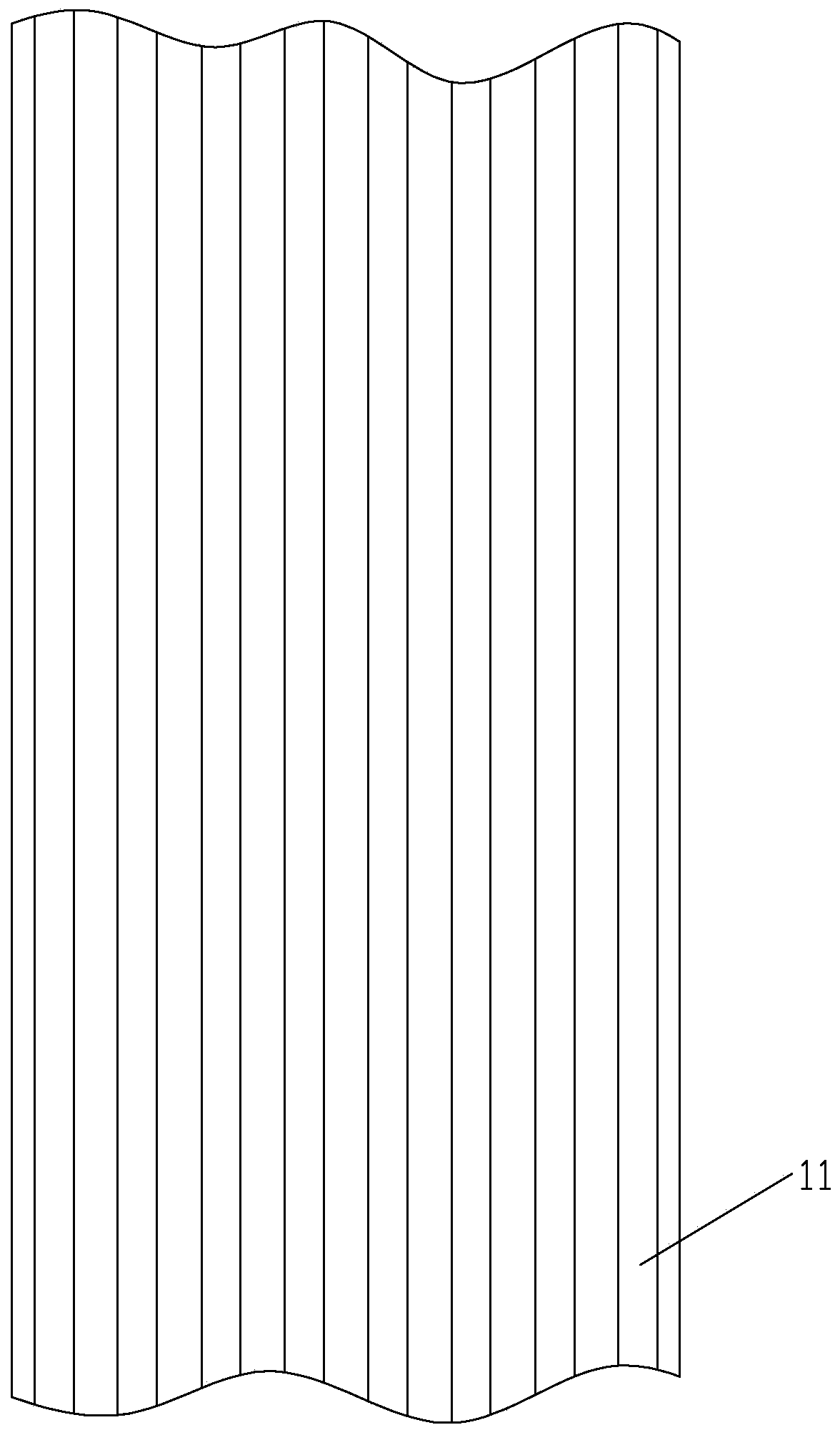

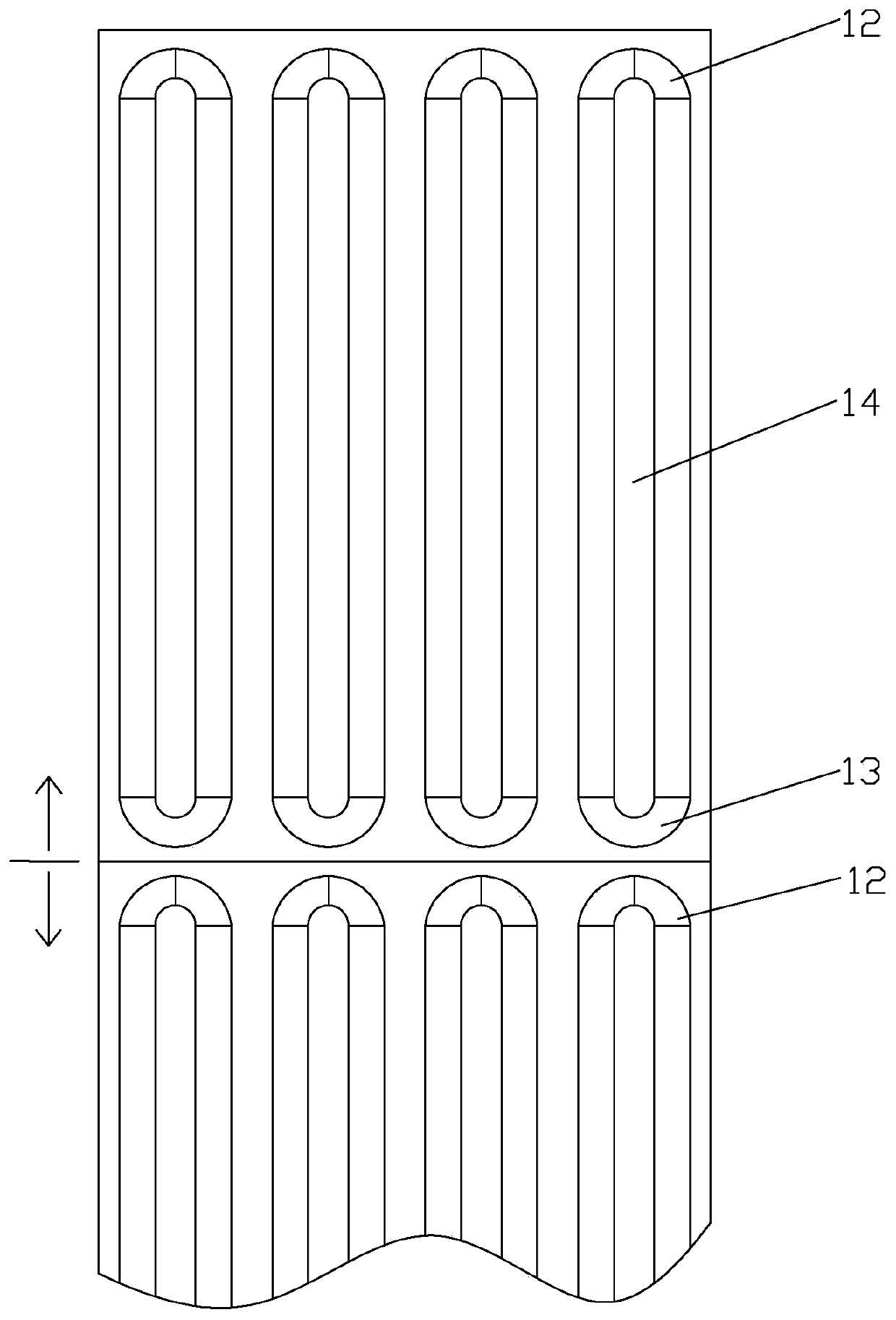

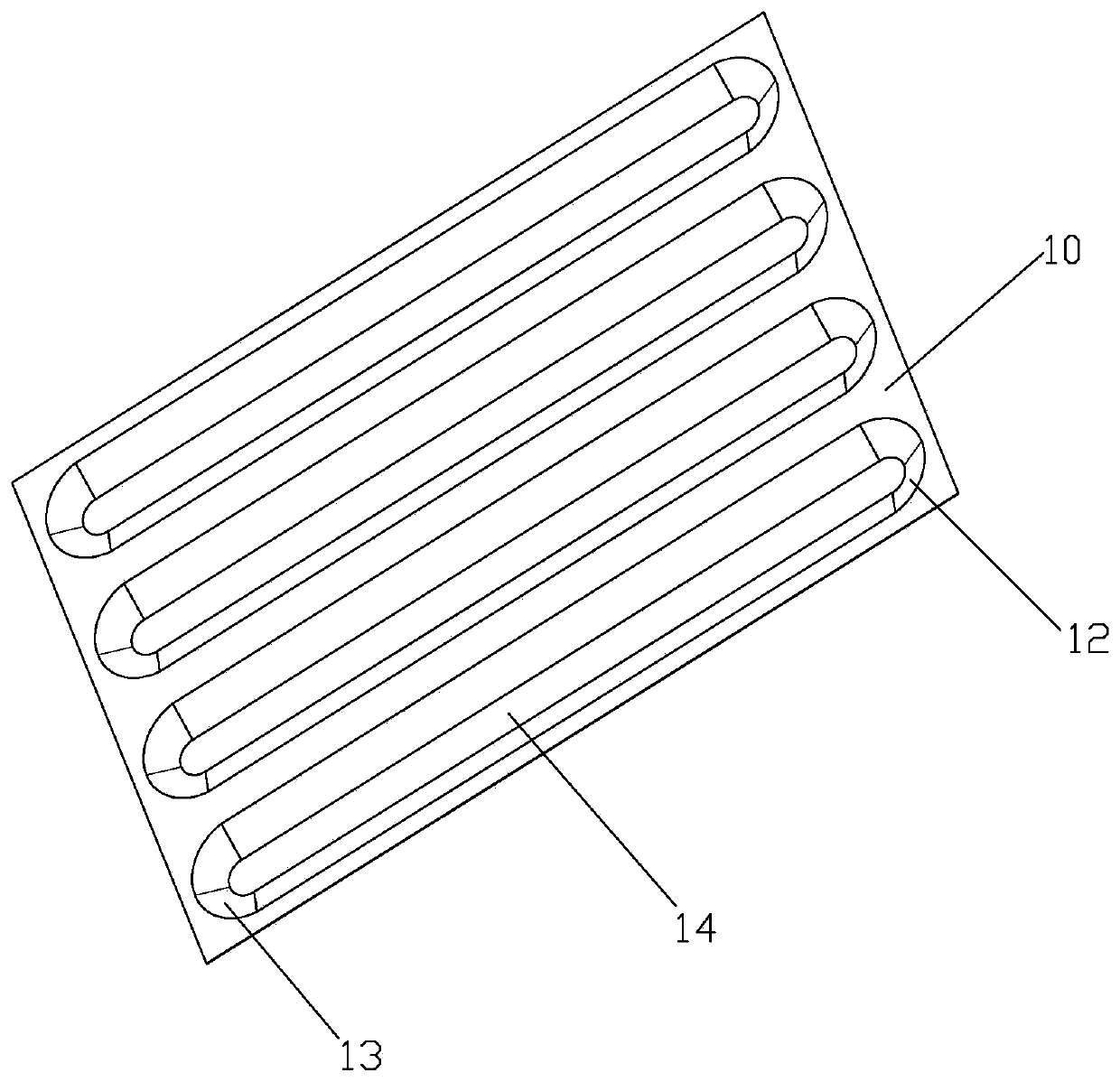

[0040] A method for forming container box panels, used for forming container box panels 10, extruding continuous strip-shaped grooves 11 from continuously rolled sheets through a first forming machine, and then forming continuous strip-shaped grooves 11 through a second forming machine. Extrude the groove head 12 and the groove tail 13. In this embodiment, the shape of the groove head 12 and the groove tail 13 is consistent, and the groove head 12 and the groove tail 13 divide the continuous strip groove 11 into independent closed strips Groove 14, at last the continuous plate is cut into independent container box plate 10, that is, the traditional cut-off, molding is changed into, the first molding, the second molding, cutting, please refer to the figure Figure 1 to Figure 4 , figure 1 Corresponding to the first molding, figure 2 Corresponding to the second molding, image 3 and Figure 4 Corresponding to the complete container board 10 . The cutting off step can be with ...

Embodiment 2

[0045] A container box plate forming device, for the above-mentioned container box plate forming method, includes a first forming machine (not shown), a second forming machine and a cutting mechanism installed in sequence.

[0046] The first forming machine extrudes continuous bar-shaped grooves 11 on the continuous plate, and the number of bar-shaped grooves 11 is set according to actual needs or standards, and the present embodiment is four.

[0047] The second molding machine extrudes a groove head 12 and a groove tail 13 on the continuous strip groove 11 , and the groove head 12 and groove tail 13 surround the strip groove 11 into an independent closed strip groove 14 .

[0048] The cutting mechanism cuts continuous boards into independent container panels 10, and the cutting mechanism is installed on the second forming machine, or, in other embodiments, the cutting mechanism is installed independently.

[0049] In this embodiment, the first molding machine includes extrus...

Embodiment 3

[0059] A molding machine is the second molding machine in the above-mentioned embodiments.

[0060] From the above description of the present invention, it can be seen that compared with the prior art, a container box plate forming method, device and forming machine of the present invention perform the first forming, the second forming and cutting of the continuously rolled plates. , to replace the traditional process of cutting first and forming again, overcome the problems of manual or mechanical handling and repositioning before forming after the plate is cut first in the traditional process, reduce the complexity and forming load of the forming machine, and improve the box plate The degree of automation of processing improves the processing efficiency and quality stability of products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com