Large-diameter round pipe rotary type cutting robot

A cutting robot and rotary technology, which is applied in the direction of pipe shearing device, shearing device, and attachment of shearing machine, etc., can solve the problems of poor cutting of round pipes, scratches, etc., and achieve the goal of improving safety and convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

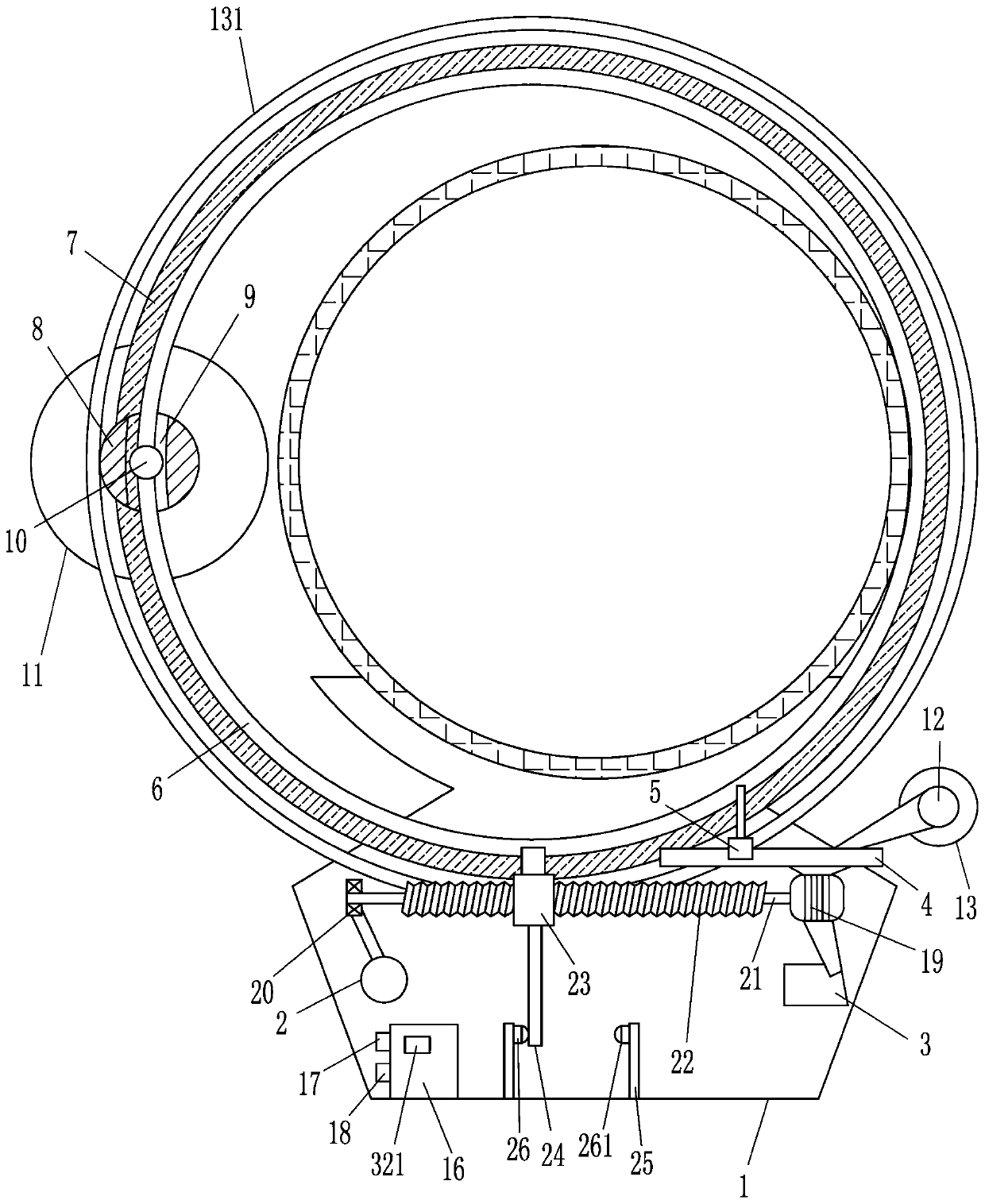

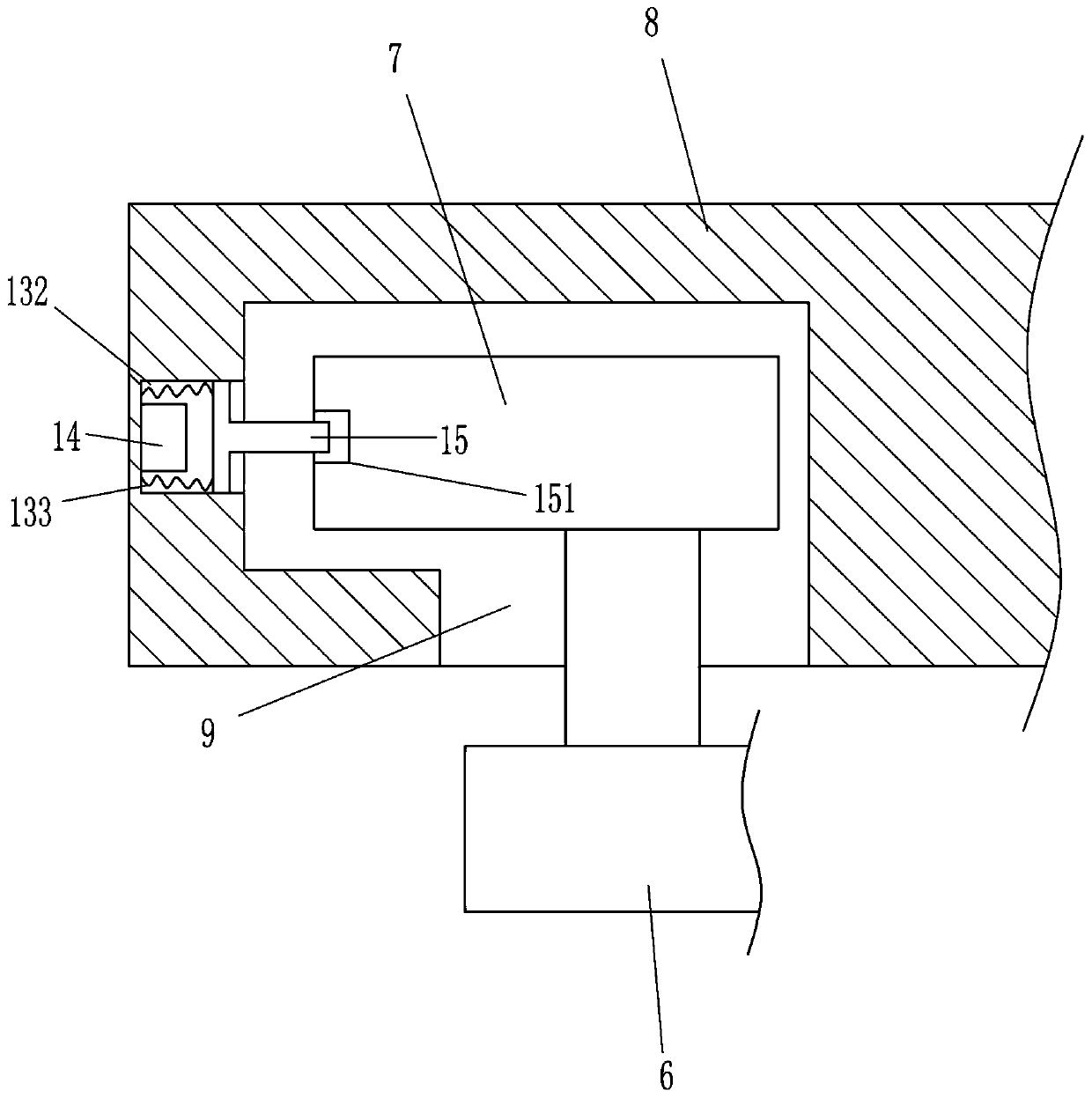

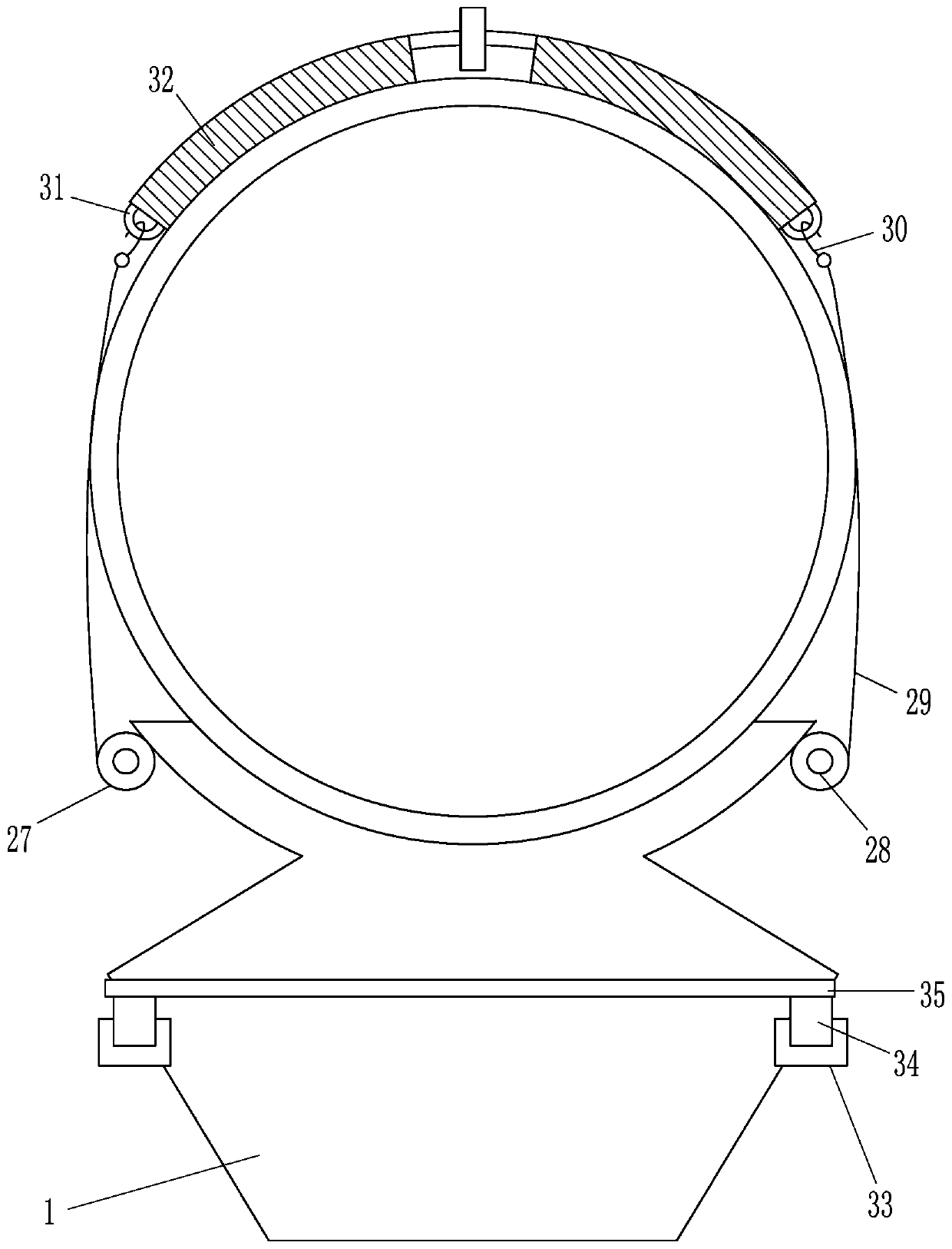

[0018] A large-diameter circular pipe rotary cutting robot, such as Figure 1-5 As shown, it includes a mounting table 1, a left mounting block 2, a right mounting block 3, a first sliding rail 4, a first sliding block 5, a moving ring rod 6, a ring clamping plate 7, a rotating block 8, a grip rod 10, a cutting Wheel 11, deceleration motor 12, gear 13, ring gear 131, spring 133, electromagnetic block 14, iron rod 15, control box 16, first switch 17 and second switch 18, mounting table 1 front side middle part left and right sides are respectively provided with left The mounting block 2 and the right mounting block 3, the top of the right mounting block 3 is provided with a first slide rail 4, the right mounting block 3 is connected with the first slide rail 4 by means of bolt connection, and the sliding type on the first slide rail 4 is provided with the first slide rail 4. A slider 5, the top rear side of the first slider 5 is provided with a moving ring bar 6, the first slid...

Embodiment 2

[0020] A large-diameter circular pipe rotary cutting robot, such as Figure 1-5 As shown, it includes a mounting table 1, a left mounting block 2, a right mounting block 3, a first sliding rail 4, a first sliding block 5, a moving ring rod 6, a ring clamping plate 7, a rotating block 8, a grip rod 10, a cutting Wheel 11, deceleration motor 12, gear 13, ring gear 131, spring 133, electromagnetic block 14, iron rod 15, control box 16, first switch 17 and second switch 18, mounting table 1 front side middle part left and right sides are respectively provided with left The mounting block 2 and the right mounting block 3, the top of the right mounting block 3 is provided with a first slide rail 4, the first slide rail 4 is slidably provided with a first slide block 5, and the rear side of the top of the first slide block 5 is provided with a moving ring Rod 6, the middle part of the left front side of the moving ring rod 6 is provided with a grip bar 10, the rear side of the moving...

Embodiment 3

[0023] A large-diameter circular pipe rotary cutting robot, such as Figure 1-5As shown, it includes a mounting table 1, a left mounting block 2, a right mounting block 3, a first sliding rail 4, a first sliding block 5, a moving ring rod 6, a ring clamping plate 7, a rotating block 8, a grip rod 10, a cutting Wheel 11, deceleration motor 12, gear 13, ring gear 131, spring 133, electromagnetic block 14, iron rod 15, control box 16, first switch 17 and second switch 18, mounting table 1 front side middle part left and right sides are respectively provided with left The mounting block 2 and the right mounting block 3, the top of the right mounting block 3 is provided with a first slide rail 4, the first slide rail 4 is slidably provided with a first slide block 5, and the rear side of the top of the first slide block 5 is provided with a moving ring Rod 6, the middle part of the left front side of the moving ring rod 6 is provided with a grip bar 10, the rear side of the moving ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap