Efficient book production process

A production process and book technology, applied in the field of high-efficiency book production technology, can solve problems such as reduced production efficiency and time-consuming, and achieve the effects of reducing workload, ensuring bonding firmness, and high cost-sharing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

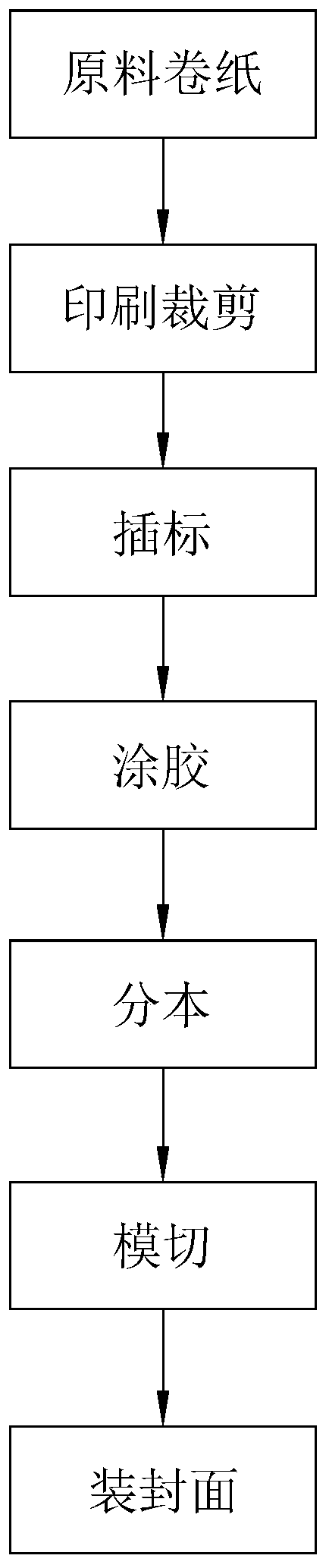

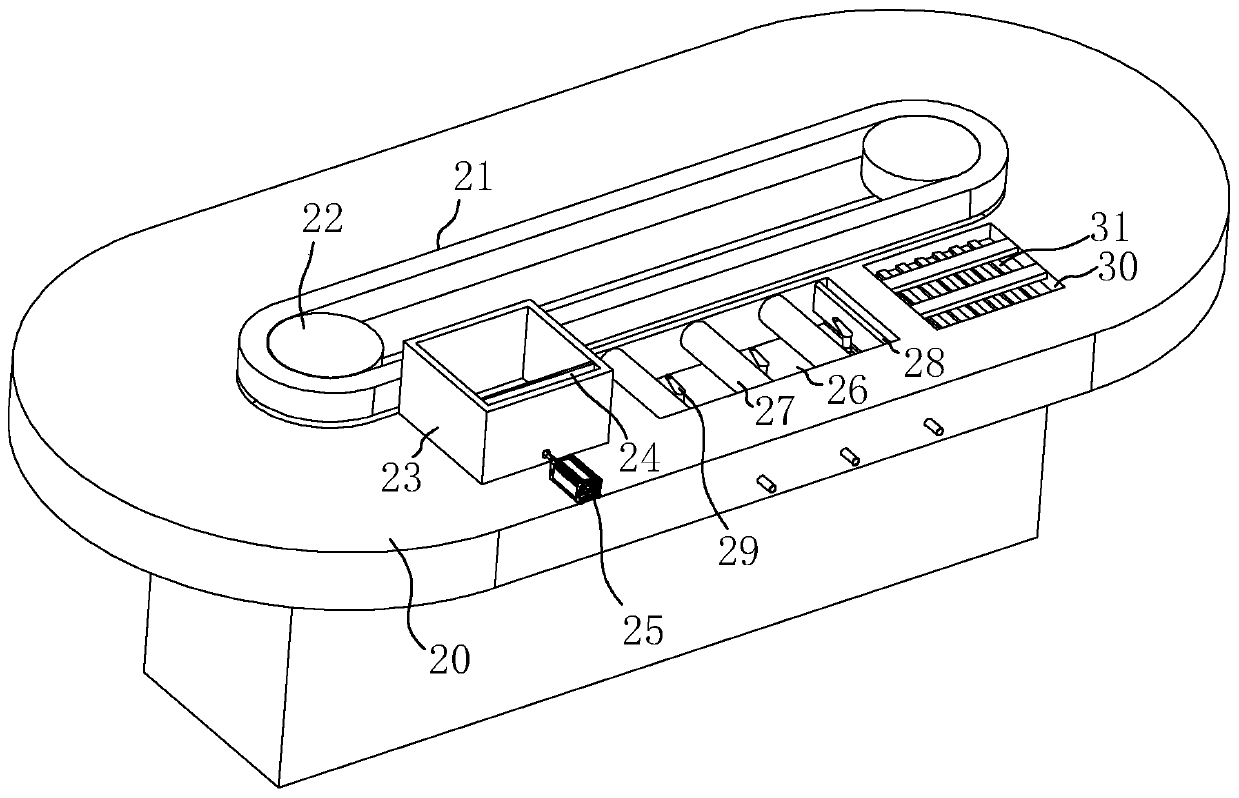

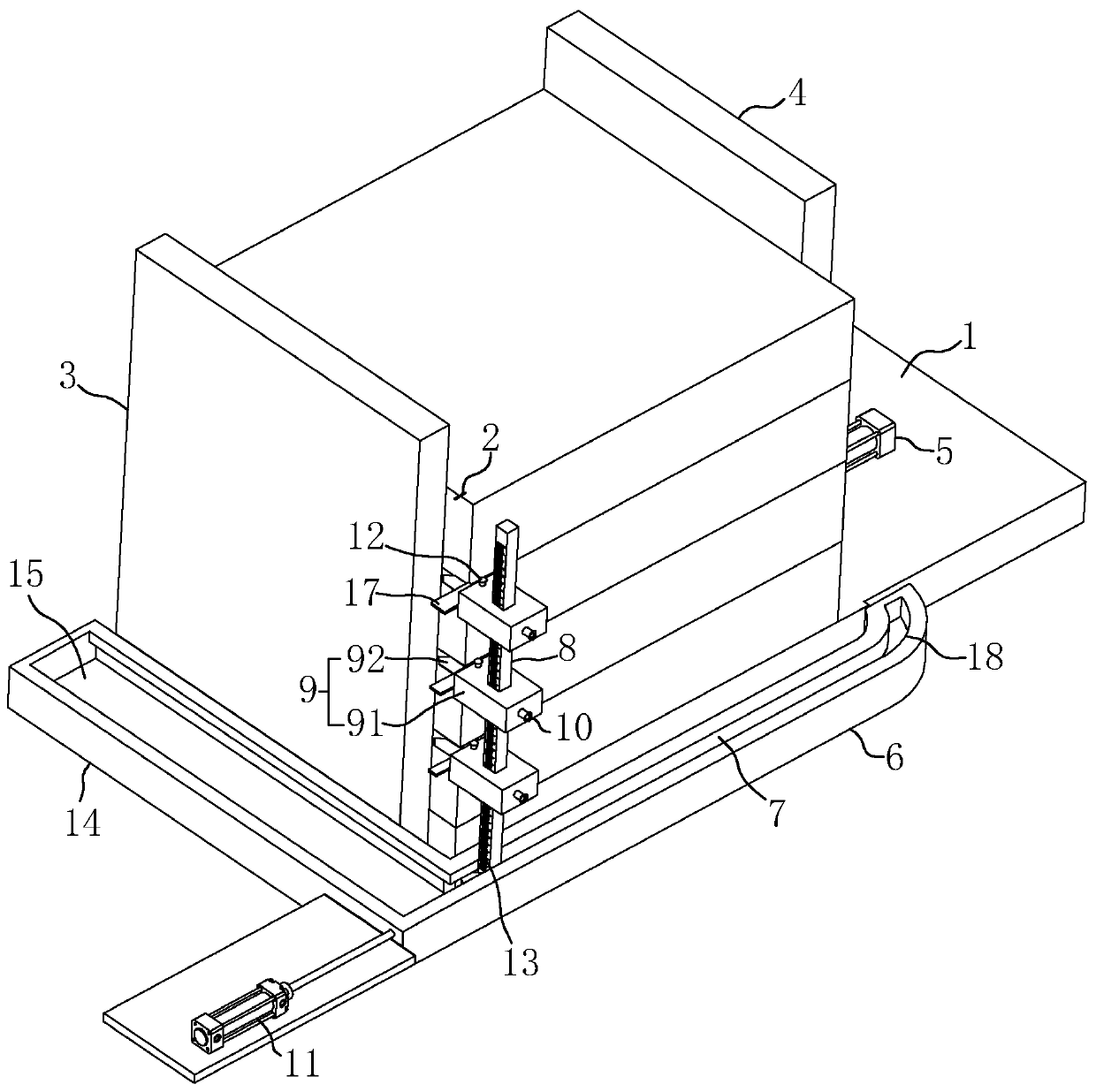

[0039] A book efficient production process such as figure 1 As shown, it mainly includes raw material roll paper, printing and cutting, label insertion, gluing, bookkeeping, die-cutting, and cover loading. The raw material roll paper is printed on an ink printing machine to realize the required graphic printing. On the roll paper, it is cut off by the cutting mechanism of the ink printing machine during the period, and the cut paper is stacked on the receiving place of the ink printing machine in turn, and an automatic label inserting machine is installed at the receiving place, and the automatic label inserting machine passes through Count and insert labels 2 between the same amount of paper to avoid the subsequent manual counting of the quantity, then place the stacked printed paper on the gluing machine and apply glue on one side, and use the dividing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com