Continuous high-grade biosafety laboratory wastewater inactivating device and method

A biosafety and laboratory technology, applied in the field of wastewater treatment equipment, can solve problems such as large biological risks, uneven heating, and dead angles, and achieve the effects of reducing biological risks, ensuring reliability, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

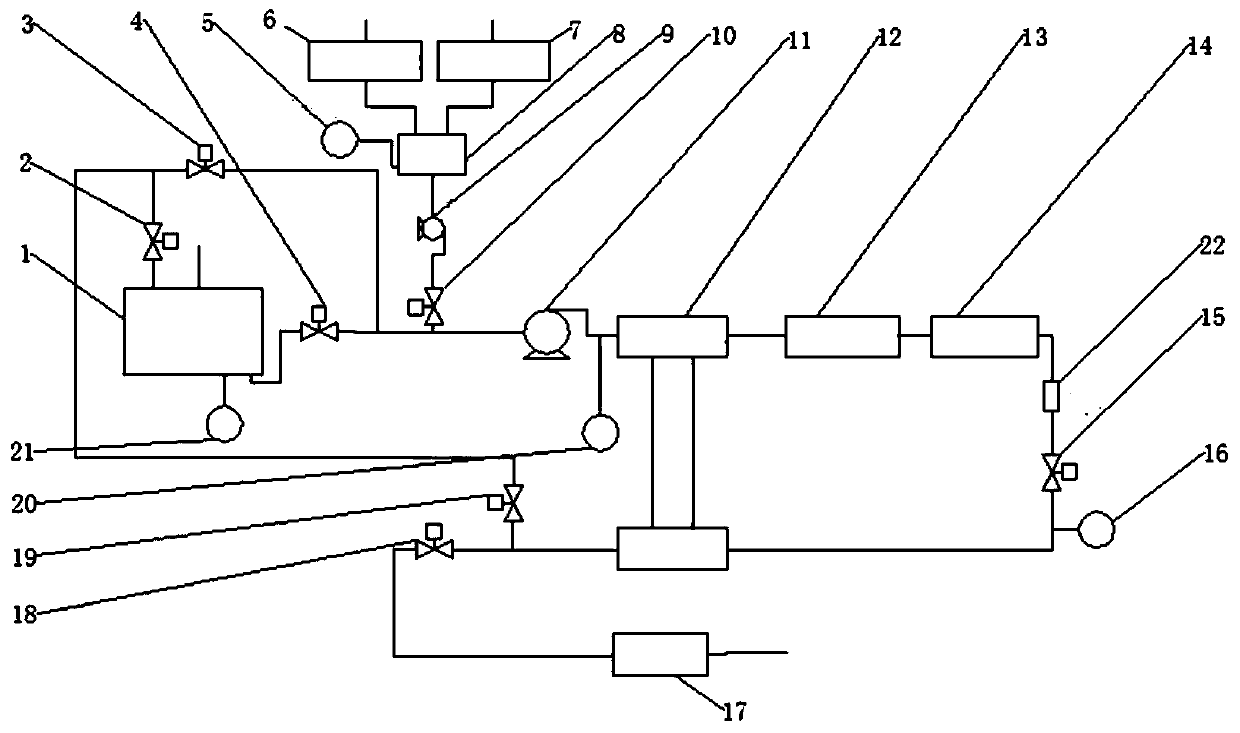

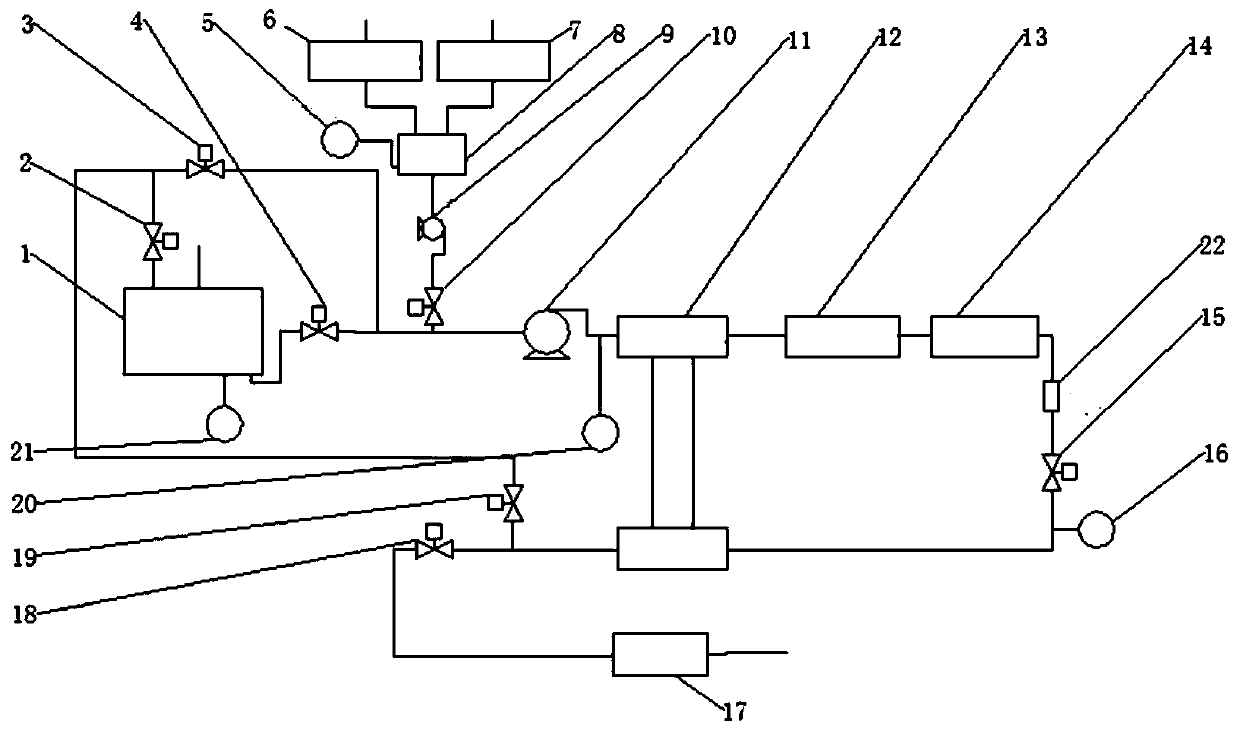

[0025] Such as figure 1 As shown, a continuous high-level biosafety laboratory wastewater inactivation device includes a wastewater collection tank 1 and a storage tank 8, which is connected to a second electric heater 6 and a freezer 7 through pipelines, and the storage tank The tank 8 is provided with a second thermometer 5, the storage tank 8 is connected to one end of the second on-off valve 10 through the second electric pump 9, and the other end of the second on-off valve 10 is connected to one end of the first on-off valve 4 and the sixth on-off valve 3 respectively. One en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com