Method for monitoring falling off of distributing chute of blast furnace

A technology for distributing chute and blast furnace, applied in blast furnace, blast furnace details, furnace and other directions, can solve problems such as heavy losses of enterprises, blast furnace production hazards, no alarm function of chute operation status, etc., and achieve the effect of improving safety factor and reducing blast furnace losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

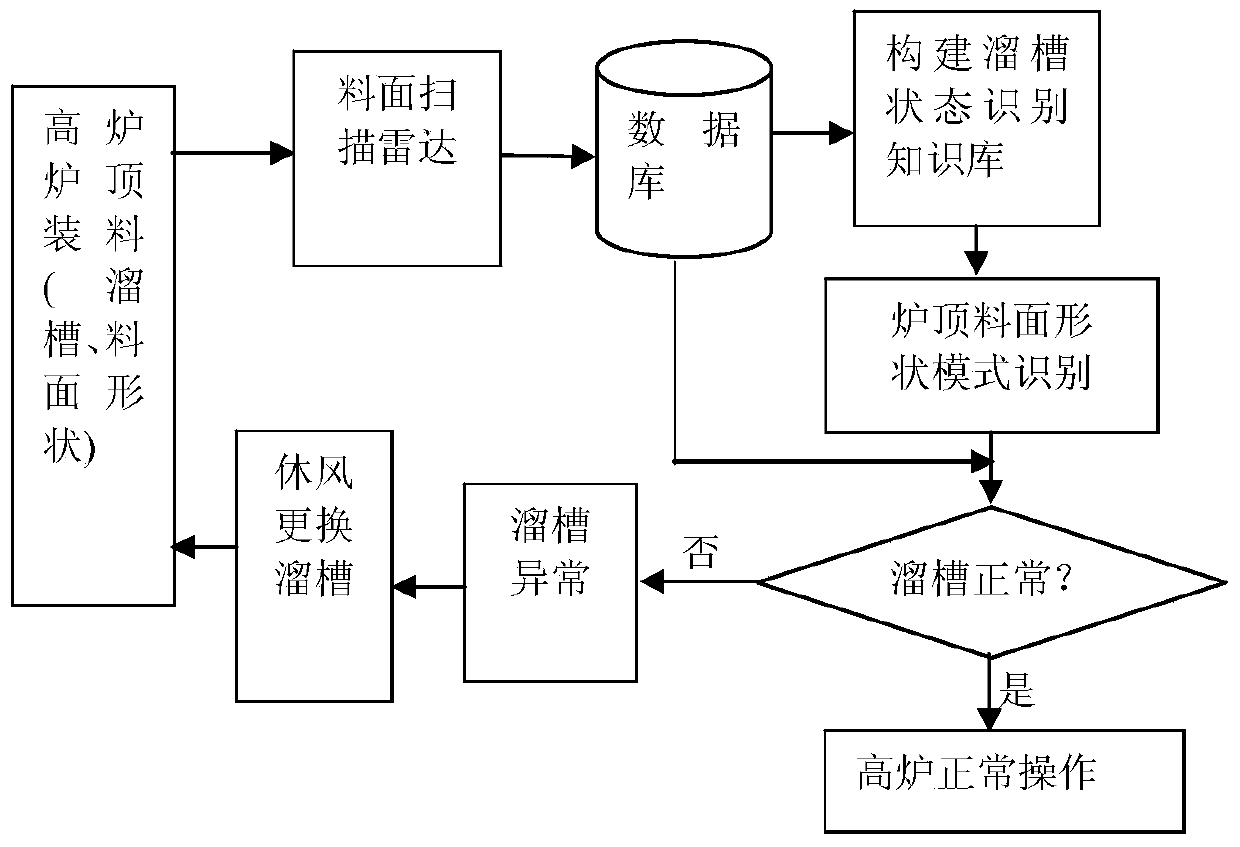

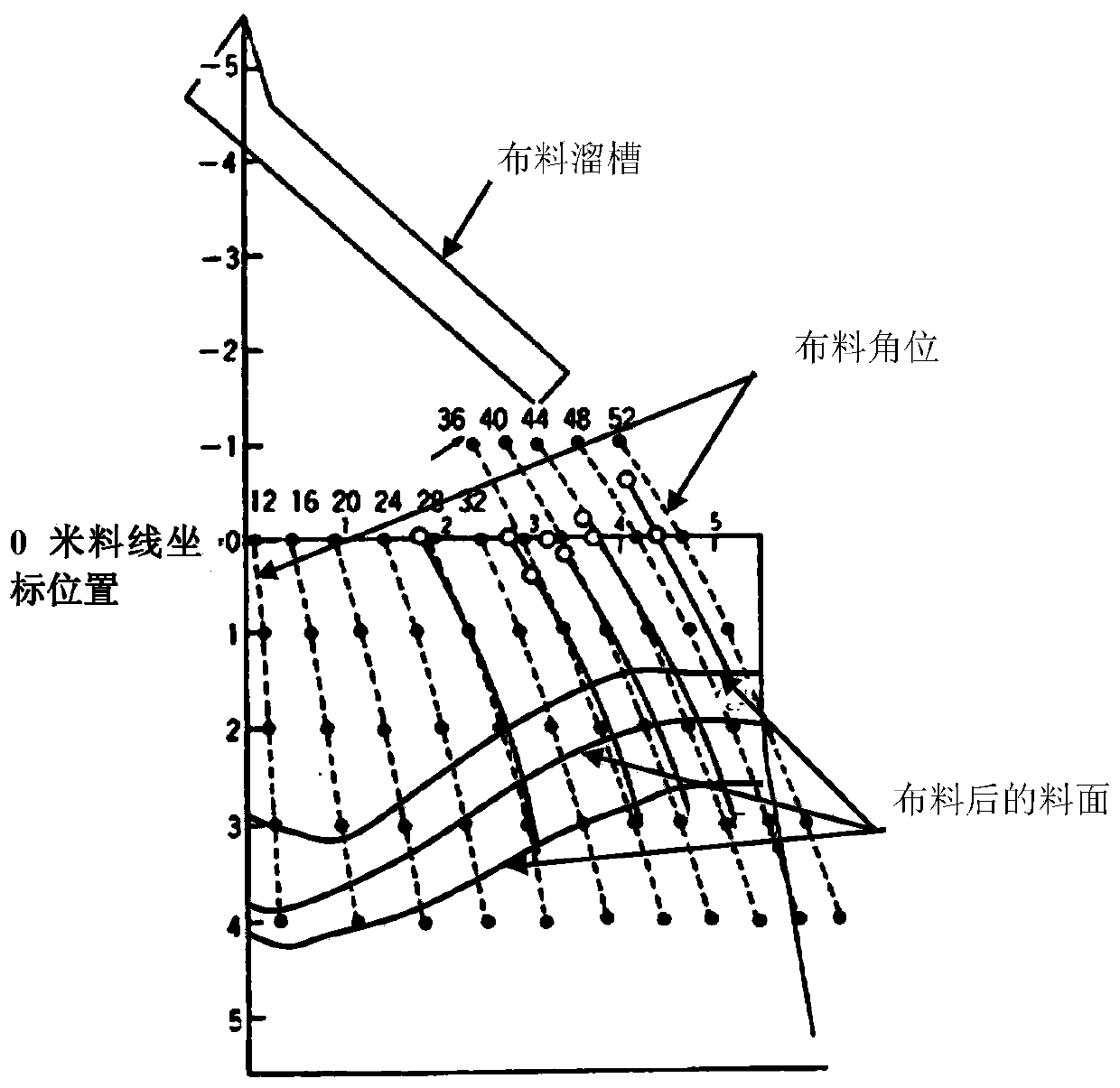

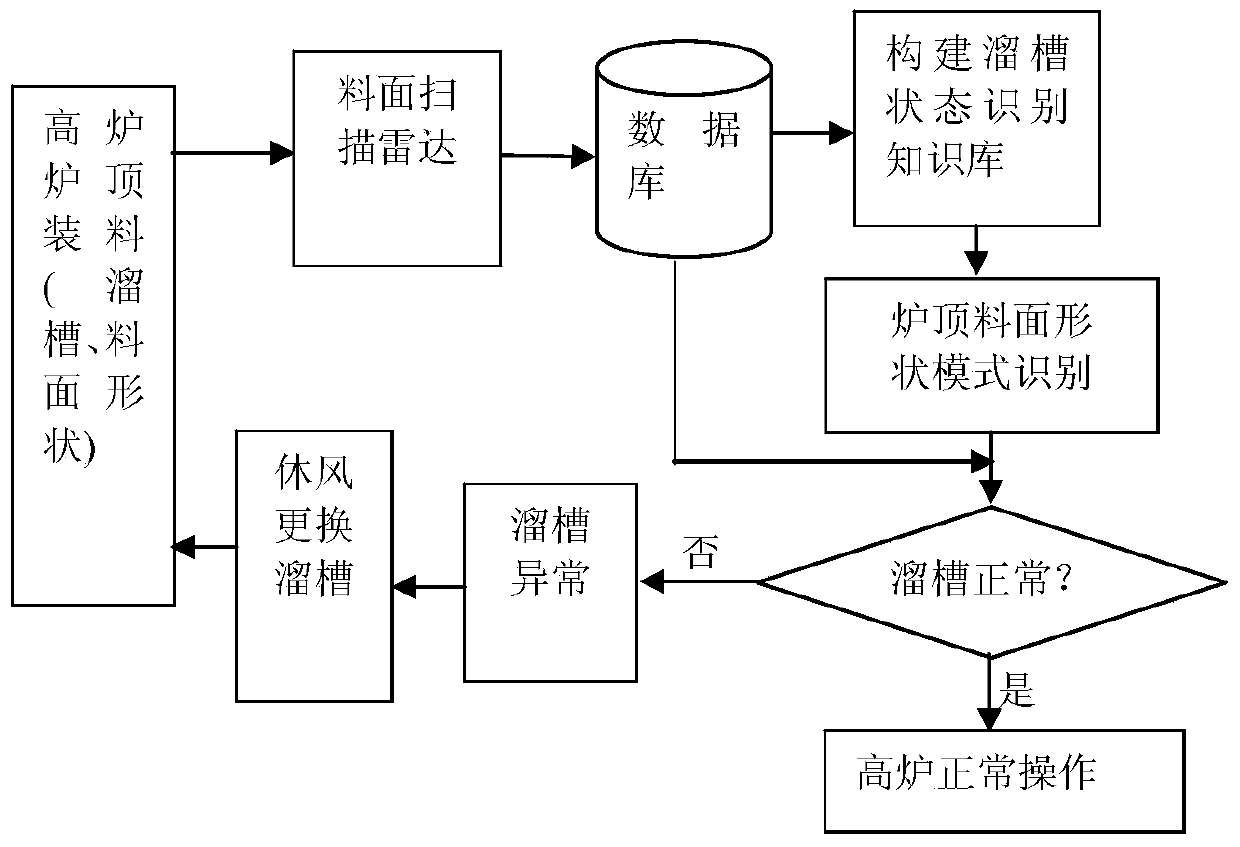

[0029] Such as figure 1 , figure 2 As shown, this embodiment uses 3200m 3 Taking a blast furnace as an example, a method for monitoring the falling of a blast furnace distribution chute of the present invention will be described in detail.

[0030] In this embodiment, the radius of the furnace top circumference is 4.5m, the chute length is 4m, and the semicircular chute is used for distributing.

[0031] The typical cloth matrix is shown in the table below. A batch of materials includes coke and ore, and the coke and ore need to be filled with a set number of turns in the chute.

[0032] Table 1: Typical cloth matrix

[0033] Chute angle1110987654321 Coke, the number of cloth loops00332210003 Ore, cloth circle number00332200000

[0034] In this embodiment, the batch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com