Template machine and template in-position detection device thereof

A detection device and template machine technology, applied in cloth feeding mechanism, sewing machine components, textiles and paper making, etc., can solve the problems of complex structure and high cost of the detection device, and achieve the effect of simplifying the structure and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

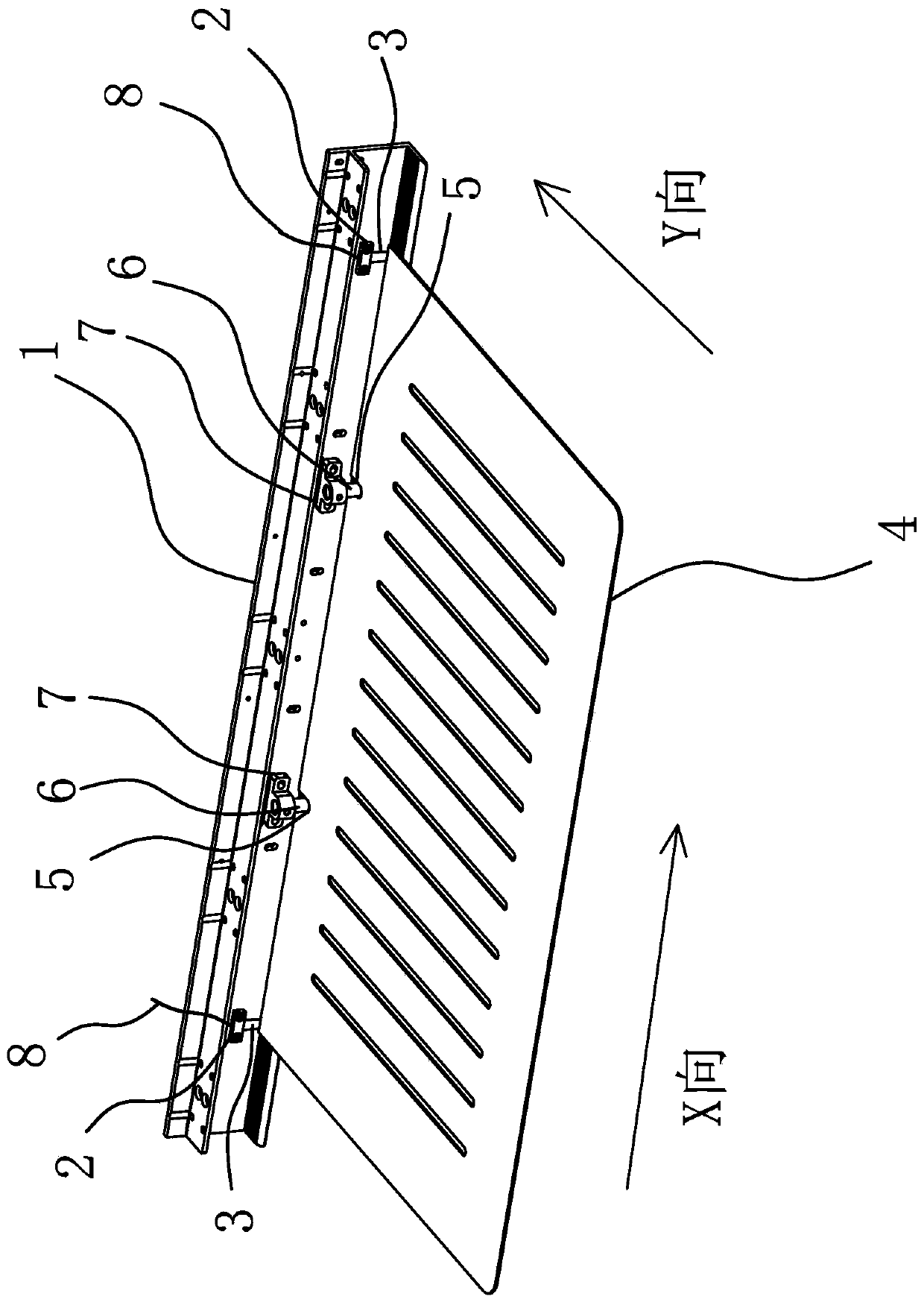

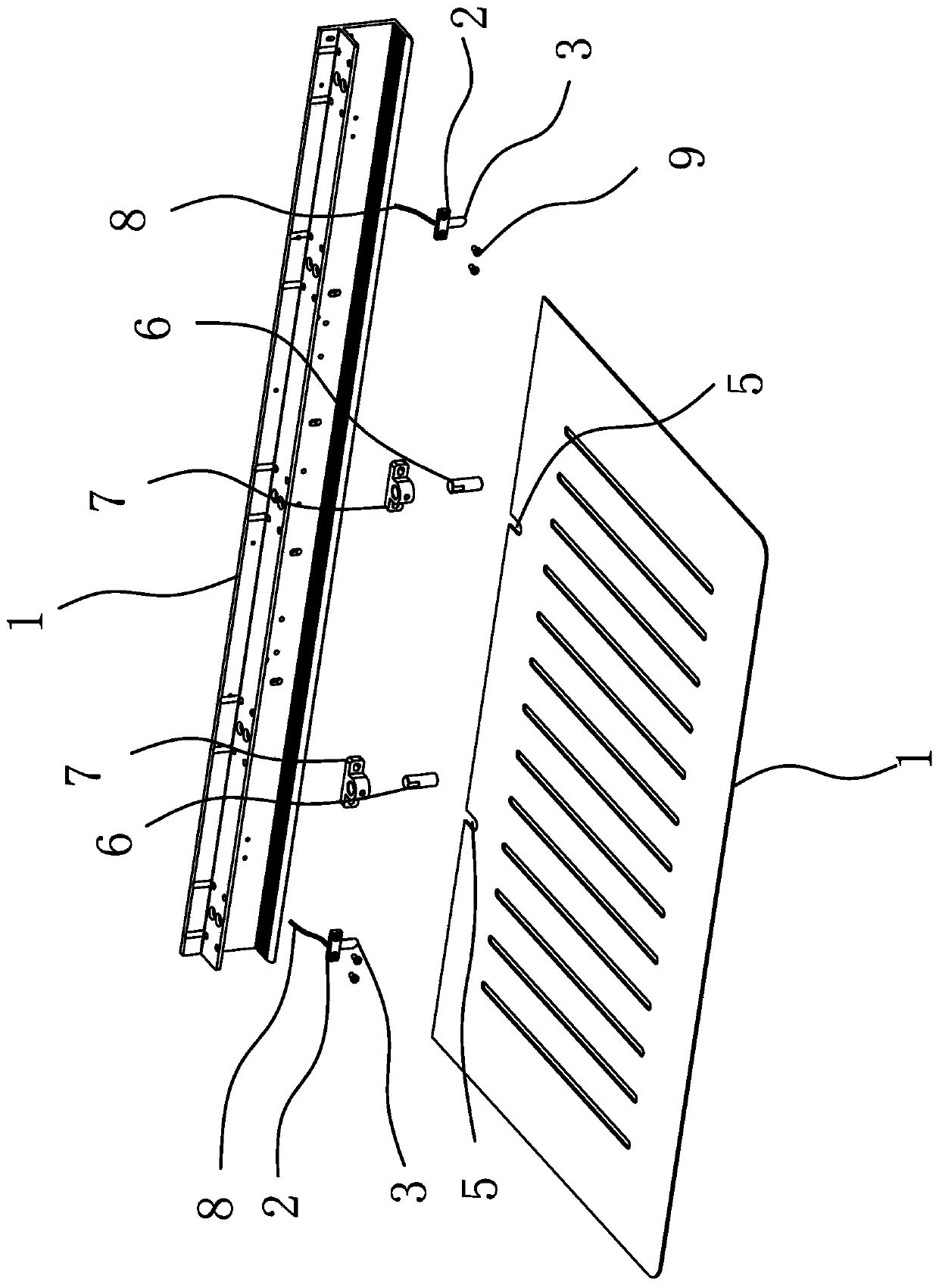

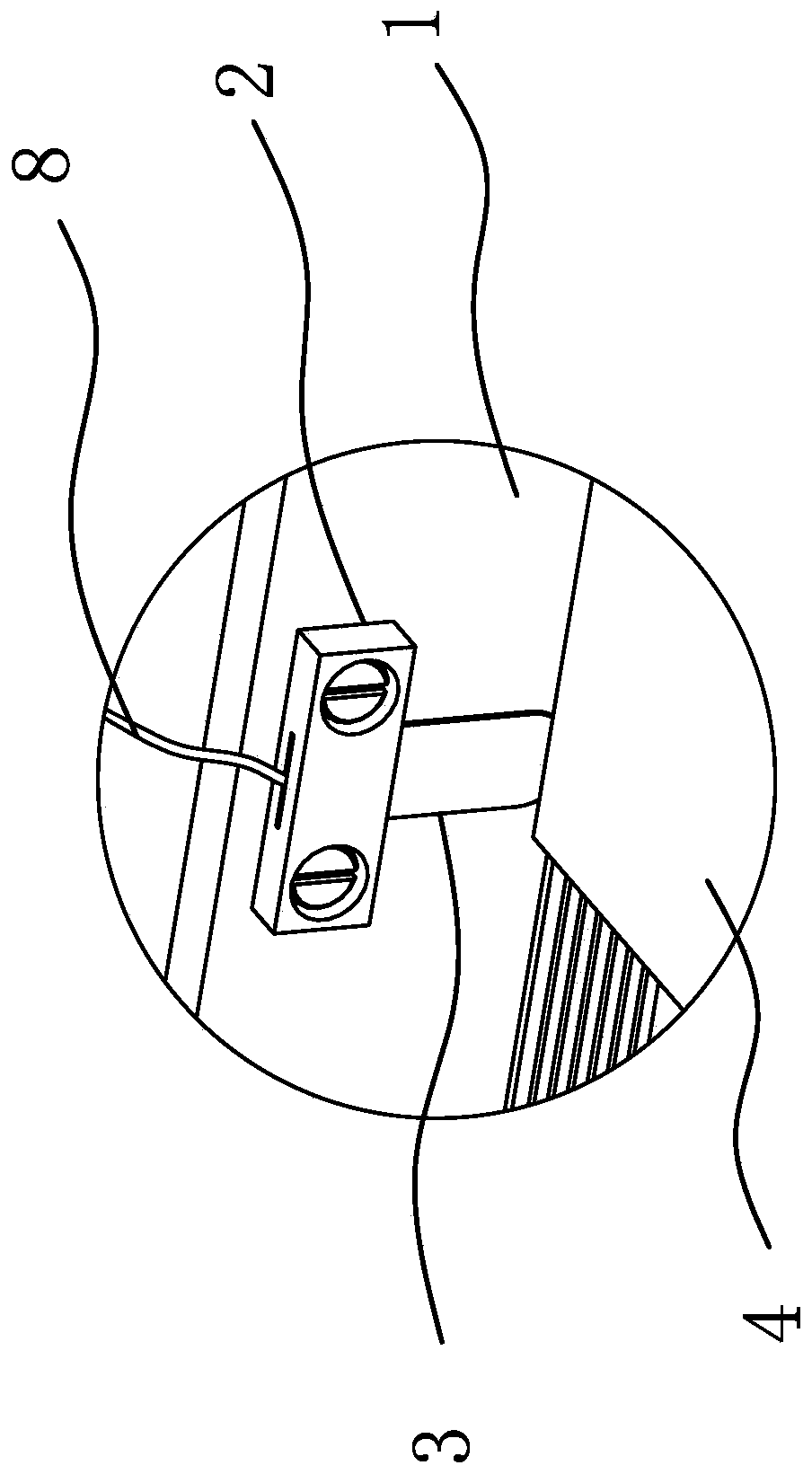

[0032] Such as figure 1 , figure 2 As shown, the template in-position detection device includes a pressure frame 1, an insulating seat 2, a conductive sheet 3, an electric control system and a template 4. Wherein, the press frame 1 is distributed along the X-direction of the template machine, and can conduct electricity. In this embodiment, the press frame 1 can be made of conductive metal. The insulating seat 2 is arranged on the pressure frame 1. In the present embodiment, the insulating seat 2 is preferably made of non-metallic insulating material, such as ceramics, and the installation of the insulating seat 2 can provide a through hole on the insulating seat 2, and the pressure frame Corresponding threaded holes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com