Asphalt foaming device and working method thereof

A foaming device and asphalt technology, applied in the directions of roads, road repair, roads, etc., can solve the problems of waste of resources, waste of resources, environment, water and soil loss, etc., to improve the mixing uniformity, improve the mixing effect, and increase the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

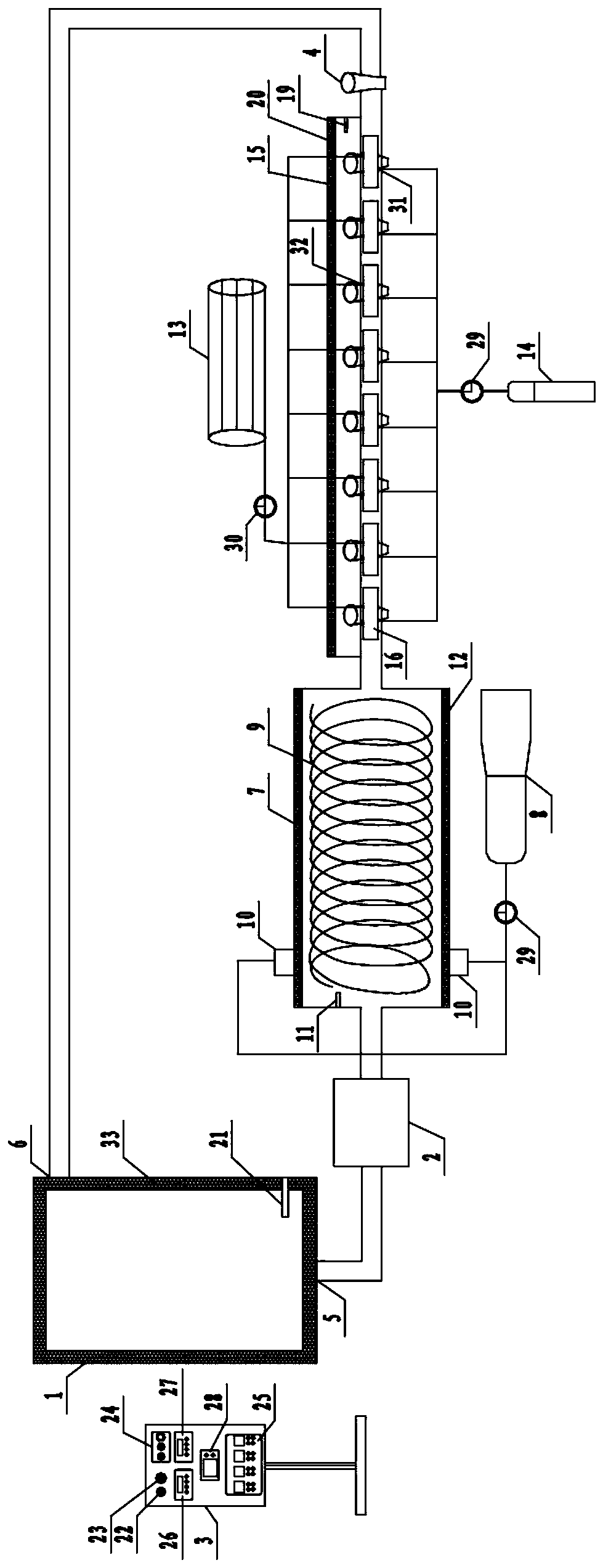

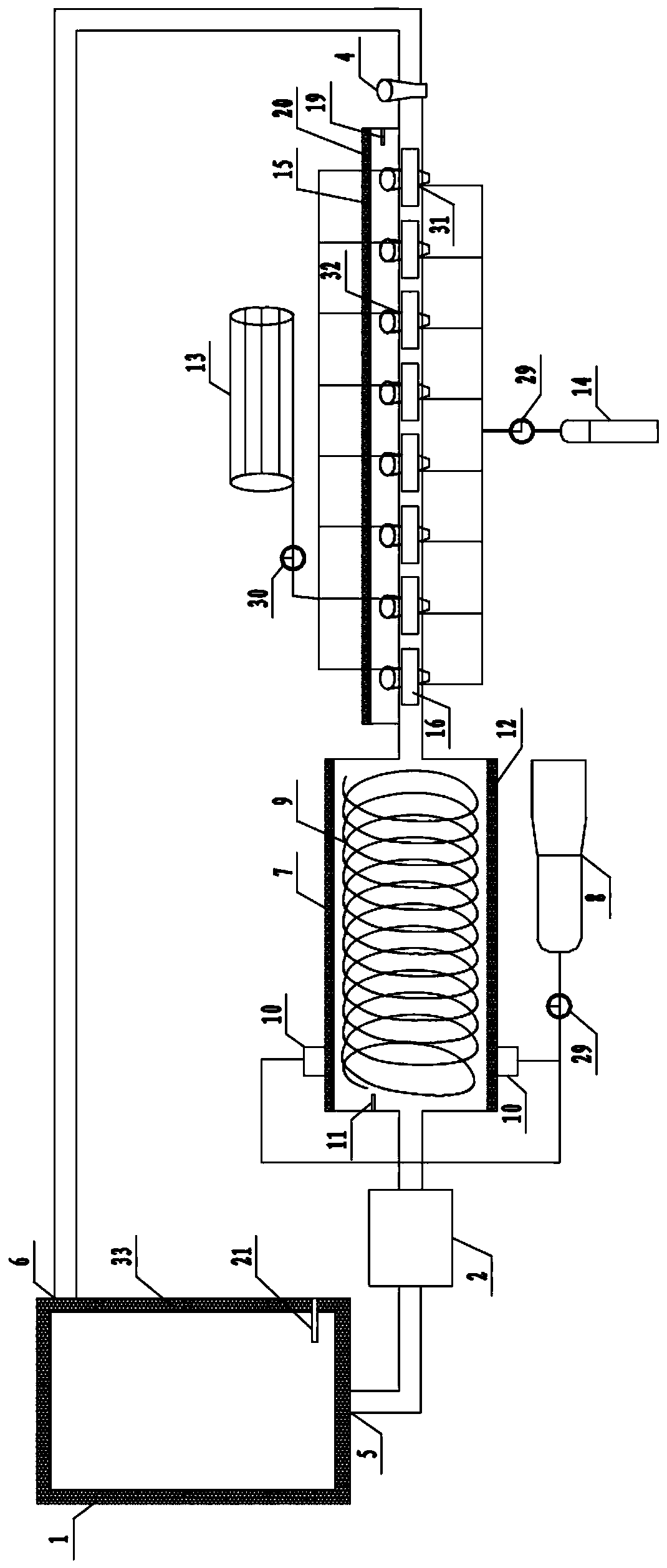

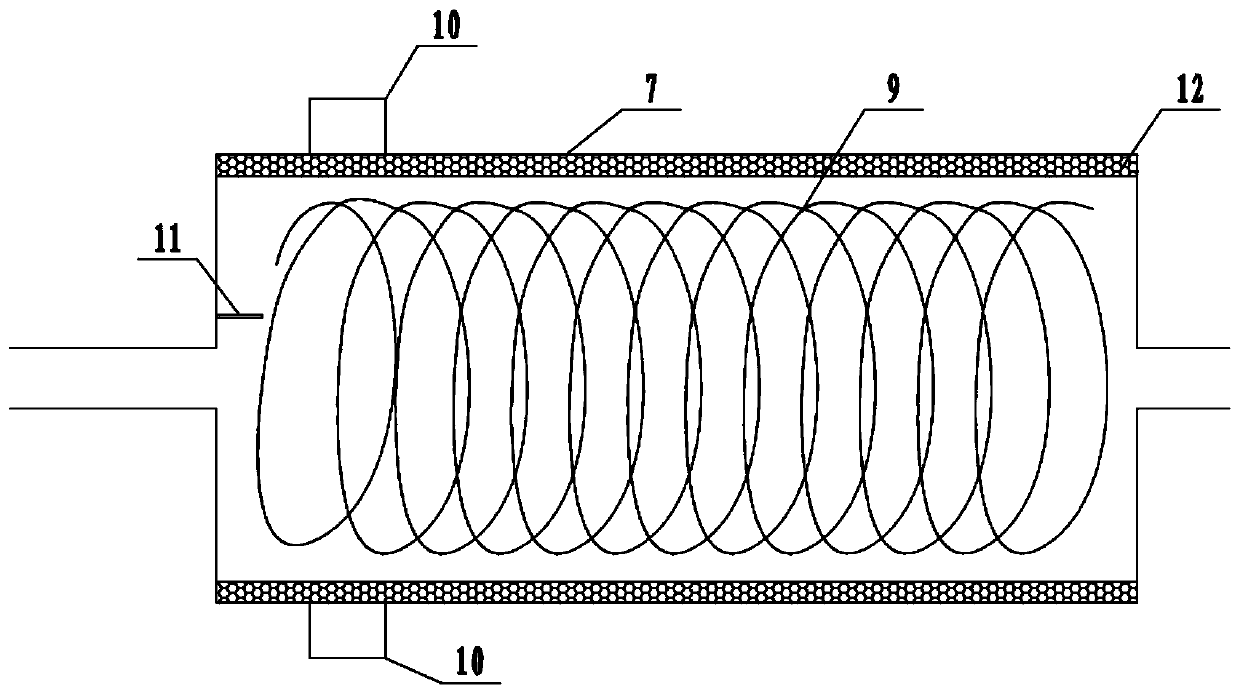

[0036] like Figure 1-Figure 5 The shown asphalt foaming device includes an asphalt tank 1, an asphalt pump 2, a centralized foaming module, a distributed foaming module, a shut-off valve 4 and an operating table 3; the first interface 5 of the asphalt tank 1 is connected to the asphalt pump The feed end of 2 is connected, the discharge end of the asphalt pump 2 is connected with the feed end of the centralized foaming module, and the discharge end of the centralized foaming module is connected with the feed end of the distributed foaming module , the discharge end of the distributed foaming module communicates with the second interface 6 of the asphalt tank 1, and the pipeline between the discharge end of the distributed foaming module and the second interface 6 of the asphalt tank 1 is installed with Stop valve 4; the bitumen tank 1, bitumen pump 2, centralized foami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com