Self-grouting and changeable floating collar and floating shoe device

A self-grouting and variable technology, which is used in wellbore/well valve devices, wellbore/well components, earth-moving drilling and mining, etc., can solve the problem that floating hoop and floating shoes do not have self-grouting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

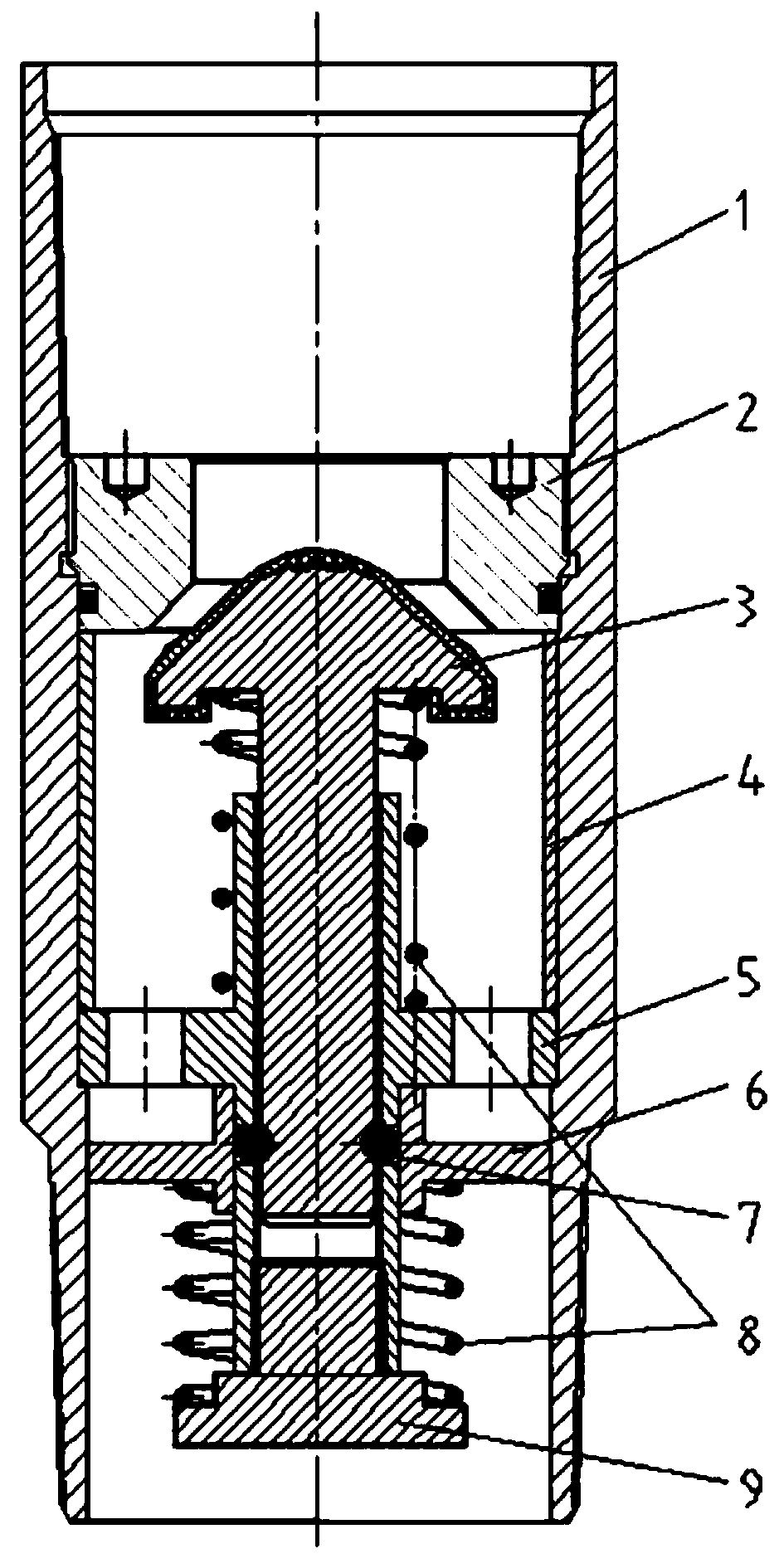

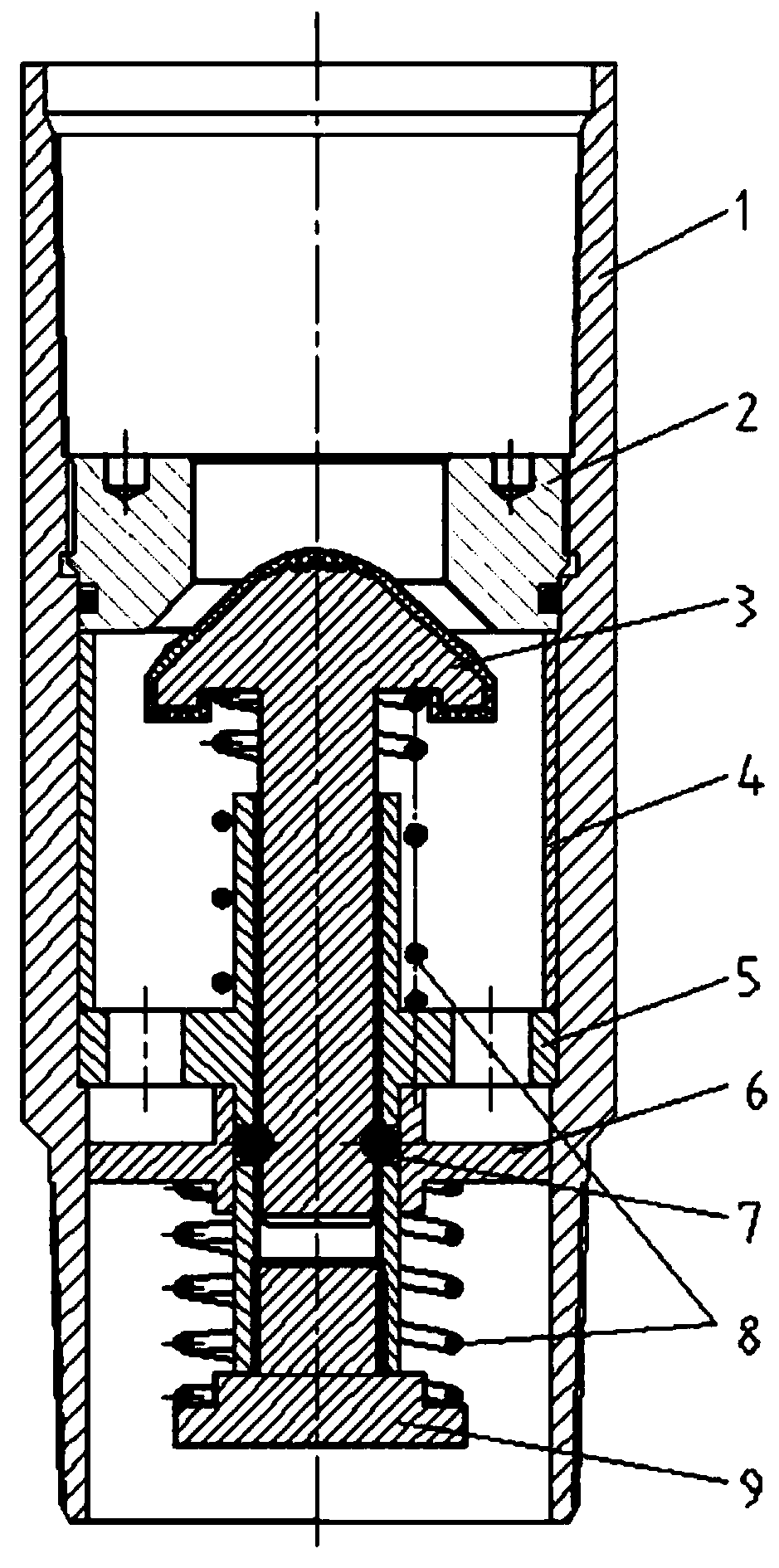

[0012] A self-grouting variable floating hoop floating shoe device, including a shell 1, a valve seat 2, a back pressure valve 3, a support sleeve 4, an orifice plate 5, a pressure sleeve 6, a copper ball 7, a spring 8, and a base 9; The housing 1 is cylindrical; the valve seat 2 is arranged in the middle and upper part of the housing 1; the middle part of the valve seat 2 is provided with a through hole; the support sleeve 4 is arranged on the inner wall of the middle part of the housing 1, and is located Below the seat 2; the orifice 5 is arranged below the support sleeve 4; the middle part of the orifice 5 is a cylindrical sleeve structure, and the orifice 5 on both sides of the cylindrical sleeve structure in the middle of the orifice 5 is provided with an orifice through hole. hole; the pressure sleeve 6 is arranged below the orifice plate 5, and the middle part of the pressure sleeve 6 is provided with a pressure sleeve through hole, and the cylindrical sleeve-like struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com