Vehicle tank and tank car

A tank and vehicle technology, applied in the field of liquefied natural gas transportation equipment, can solve the problems of inability to meet multiple unloading, low distribution efficiency, slow pressurization speed, etc., to improve distribution efficiency, high distribution efficiency, and reduce pressurization time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

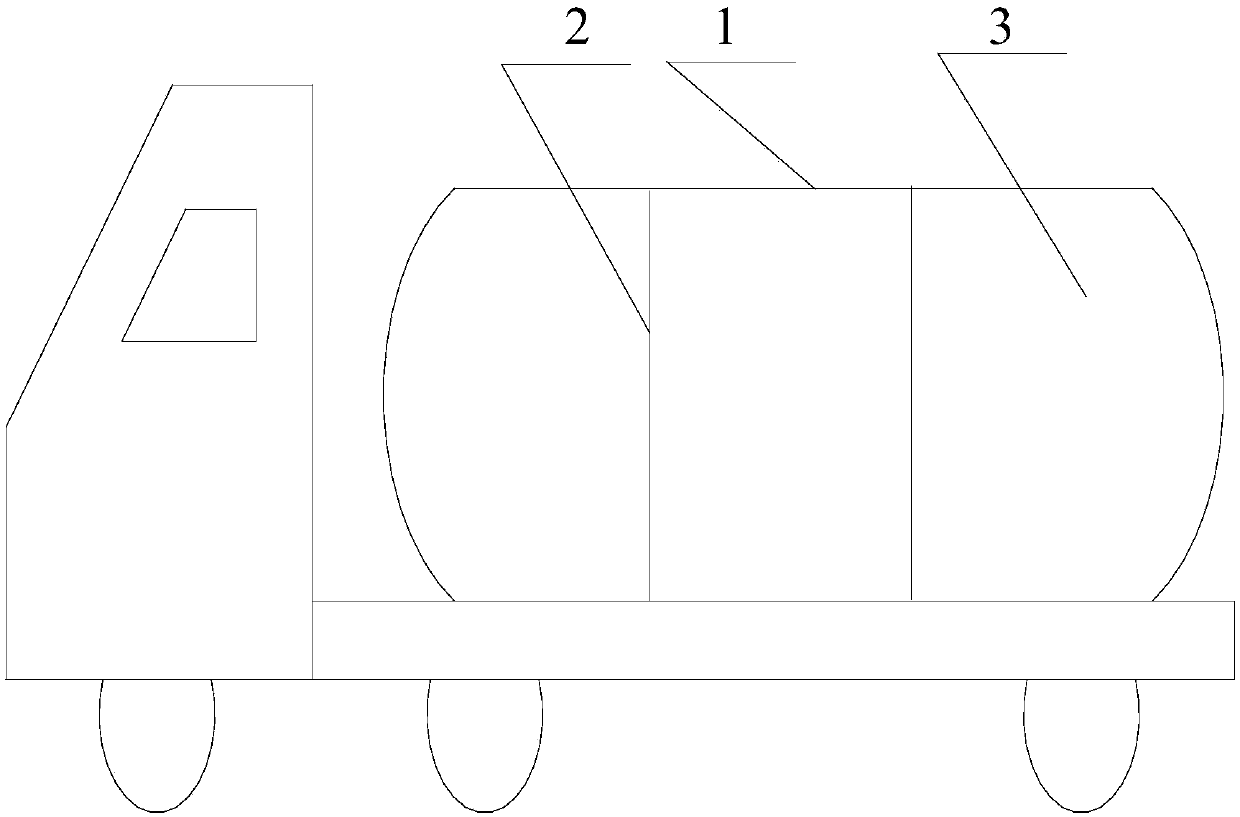

[0028] Such as figure 1 As shown, the present invention discloses a vehicle tank body, wherein the vehicle tank body includes a tank body body 1, a partition plate 2, a switch device and a supercharger.

[0029] The number of partitions 2 is multiple, and the plurality of partitions 2 are arranged in the tank body 1 to divide the tank body 1 into a first preset compartment 3 . It should be noted that the number of cabins 3 can be set according to actual needs.

[0030] The switch device is installed between the multiple compartments 3 , that is, the switch device can be installed between any two compartments 3 of the multiple compartments 3 , and the switch device can connect or close each compartment 3 .

[0031] The pressure booster can pressurize the gas in the tank main body 1 .

[0032] In the vehicle tank body disclosed by the present invention, a plurality of partitions 2 divide the vehicle tank body into a first preset cabin 3, and when in use, each cabin 3 can be cl...

Embodiment 2

[0034] In the second embodiment provided by the present invention, the vehicle tank body in this embodiment is similar in structure to the vehicle tank body in Embodiment 1, and the similarities will not be repeated, and only the differences will be introduced.

[0035] In this embodiment, it is specifically disclosed that the switch device is a valve. It should be noted that the switch device may also be other devices capable of closing or opening each compartment 3 .

[0036] Further, the present invention discloses that the number of superchargers is the same as the number of chambers 3 , and each supercharger communicates with one chamber 3 . That is, each compartment 3 is equipped with a separate supercharger, which can realize real-time pressurization of each compartment 3 .

[0037] In this embodiment, the number of cabins 3 is three as an example.

[0038] The present invention has the following advantages:

[0039] (1) It can be pressurized separately after subdivis...

Embodiment 3

[0042] In the third embodiment provided by the present invention, the vehicle tank body in this embodiment is similar in structure to the vehicle tank body in Embodiment 2, and the similarities will not be repeated, and only the differences will be introduced.

[0043] In this embodiment, it is specifically disclosed that the number of superchargers is one, and the superchargers communicate with the first preset compartments 3 respectively. That is to say, the cabins 3 are arranged in parallel with each other, and are pressurized by the same supercharger at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com