Aqueous dispersion of coenzyme q10 and preparation method thereof

A dispersion and coenzyme technology, applied in the biological field, can solve problems such as unsafe factors, excessive dosage, and potential safety hazards, and achieve the effects of wide adaptability, good effect, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

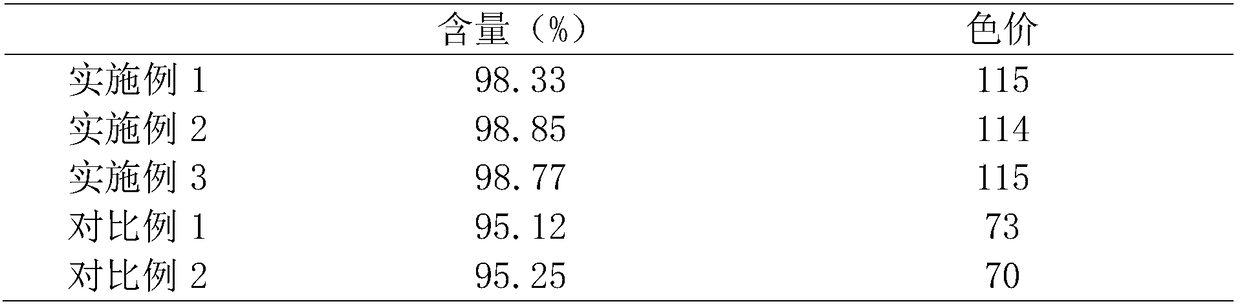

Examples

Embodiment 1

[0032] Coenzyme Q10 aqueous dispersion and preparation method thereof, specifically comprising the following steps:

[0033] 1) Preparation of raw materials: Prepare coenzyme Q10, gum arabic, lactose, emulsifier, soluble starch, co-solvent, and water according to the weight ratio of 1:0.20:0.04:0.004:0.06:0.02;

[0034] 2) Dissolve gum arabic in water, then add soluble starch, lactose, and Tween, heat to 55°C to dissolve, stir evenly, and set aside;

[0035] 3) Heat polyethylene glycol to dissolve, then add coenzyme Q10, heat to 55°C to dissolve, and set aside;

[0036] 4) Pressure treatment: put the materials processed in step 2) and step 3) into a high-pressure tank, and pressurize to 4kg / cm 2 , to make the pressure uniform, and keep it for 5-10min, and then return to normal pressure within 1-3s to obtain a mixed solution;

[0037] 5) Spray-dry the mixed solution obtained in step 4) to obtain coenzyme Q10 aqueous dispersion powder;

[0038] The coenzyme Q10 described in s...

Embodiment 2

[0045] Coenzyme Q10 aqueous dispersion and preparation method thereof, specifically comprising the following steps:

[0046] 1) Preparation of raw materials: Prepare coenzyme Q10, gelatin, D-galactose, emulsifier, soluble starch, co-solvent, and water according to the weight ratio of 1:0.30:0.02:0.006:0.04:0.04;

[0047] 2) Dissolve the gelatin with water, then add soluble starch, D-galactose, and Tween, heat to 60°C to dissolve, stir evenly, and set aside;

[0048] 3) Heat polyethylene glycol to dissolve, then add coenzyme Q10, heat to 60°C to dissolve, and set aside;

[0049] 4) Pressure treatment: put the materials processed in step 2) and step 3) into a high-pressure tank, and pressurize to 4kg / cm 2 , to make the pressure uniform, and keep it for 5-10min, and then return to normal pressure within 1-3s to obtain a mixed solution;

[0050] 5) Spray-dry the mixed solution obtained in step 4) to obtain coenzyme Q10 aqueous dispersion powder;

[0051] The coenzyme Q10 descri...

Embodiment 3

[0058] Coenzyme Q10 aqueous dispersion and preparation method thereof, specifically comprising the following steps:

[0059] 1) Preparation of raw materials: Prepare coenzyme Q10, gum arabic, lactose, emulsifier, soluble starch, co-solvent, and water according to the weight ratio of 1:0.25:0.03:0.005:0.05:0.03;

[0060] 2) Dissolve gum arabic in water, then add soluble starch, lactose, sucrose ester, heat to 55°C to dissolve, stir evenly, and set aside;

[0061] 3) Heat the poloxamer to dissolve, then add coenzyme Q10, heat to 60°C to dissolve, and set aside;

[0062] 4) Pressure treatment: put the materials processed in step 2) and step 3) into a high-pressure tank, and pressurize to 4kg / cm 2 , to make the pressure uniform, and keep it for 5-10min, and then return to normal pressure within 1-3s to obtain a mixed solution;

[0063] 5) Spray-dry the mixed solution obtained in step 4) to obtain coenzyme Q10 aqueous dispersion powder;

[0064] The coenzyme Q10 described in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com