A Multistage Multipurpose Hydraulic Booster With Variable Boosting Ratio

A technology of hydraulic booster and boosting ratio, which is applied in the direction of fluid pressure converters, mechanical equipment, etc., which can solve the problems of incapable of boosting, cumbersome disassembly process, and inability to achieve boosting with different fluids, so as to ensure boosting efficiency and precision, save boosting time, expand the use range and the effect of boosting environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

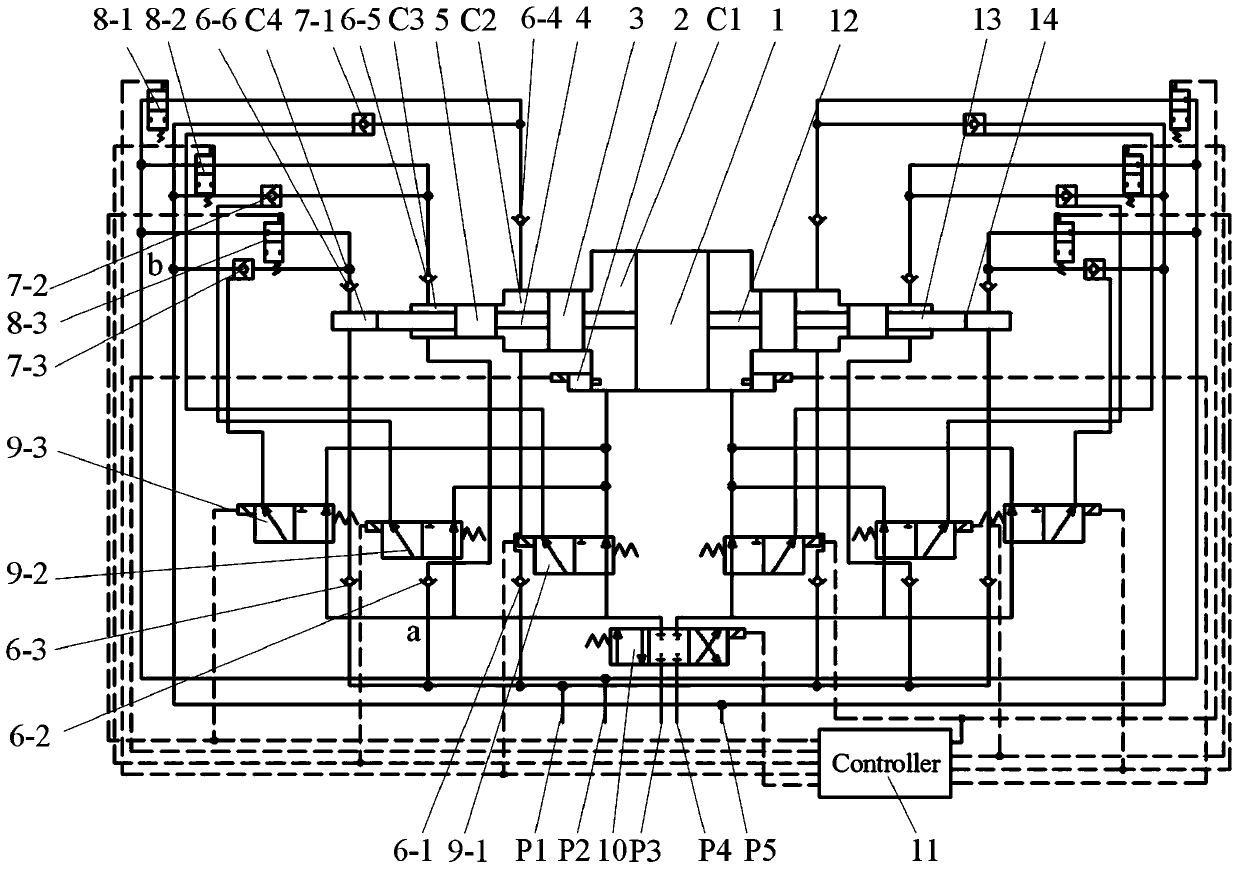

[0024] Such as figure 1As shown, a multi-stage multi-purpose hydraulic booster with a variable boost ratio includes a multi-stage boost structure, a hydraulic oil circuit and its control components, a boost fluid circuit and its control components; the multi-stage boost structure includes The supercharger casing, the high-pressure cylinder head connected to both ends of the supercharger casing, the casing is equipped with a piston, the piston rod installed at both ends of the piston and the connecting valve body, the fluid in the supercharged fluid circuit and the fluid in the hydraulic oil circuit The fluid uses the same or different media; the piston in the housing includes a transfer piston 1, two first-stage booster pistons 3, two second-stage booster pistons 5 and two third-stage booster pistons 14, and the transfer piston 1 is set at the In the middle of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com