Method for measuring earth pressure on outer side of shield tunnel

A technology of shield tunneling and measurement methods, applied in force/torque/work measuring instruments, measuring devices, force sensors in holes in stressed structures, etc., can solve the problem of unsuitable long-term monitoring of earth pressure and inability to guarantee earth pressure The outer membrane of the box is in good contact with the test soil, and it is affected by the buried state of the soil pressure box, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments and drawings, but the protection scope of the present invention is not limited to the following embodiments.

[0036] In combination with the above-mentioned drawings, an implementation case of the earth pressure measurement device outside the tunnel is proposed.

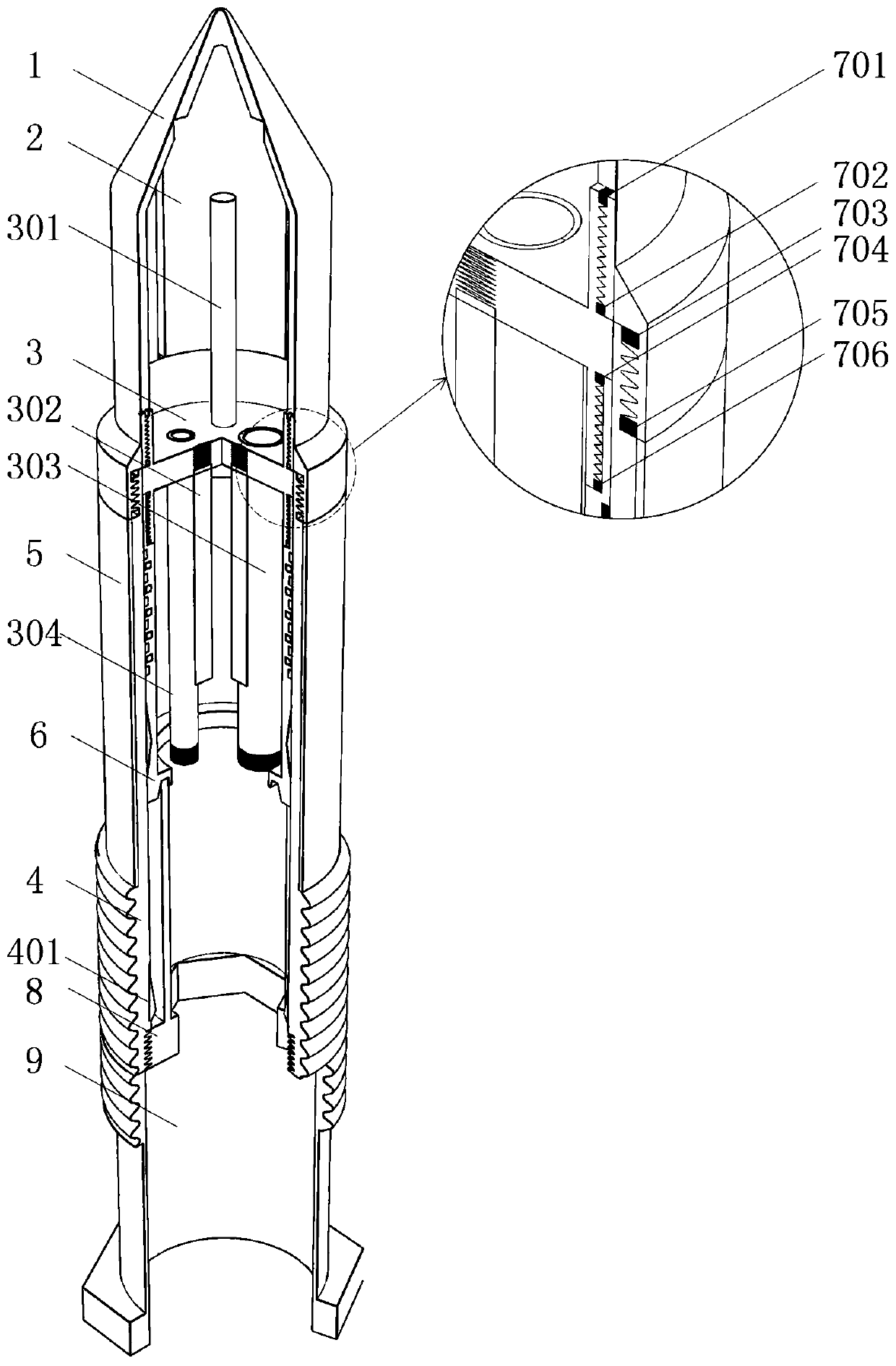

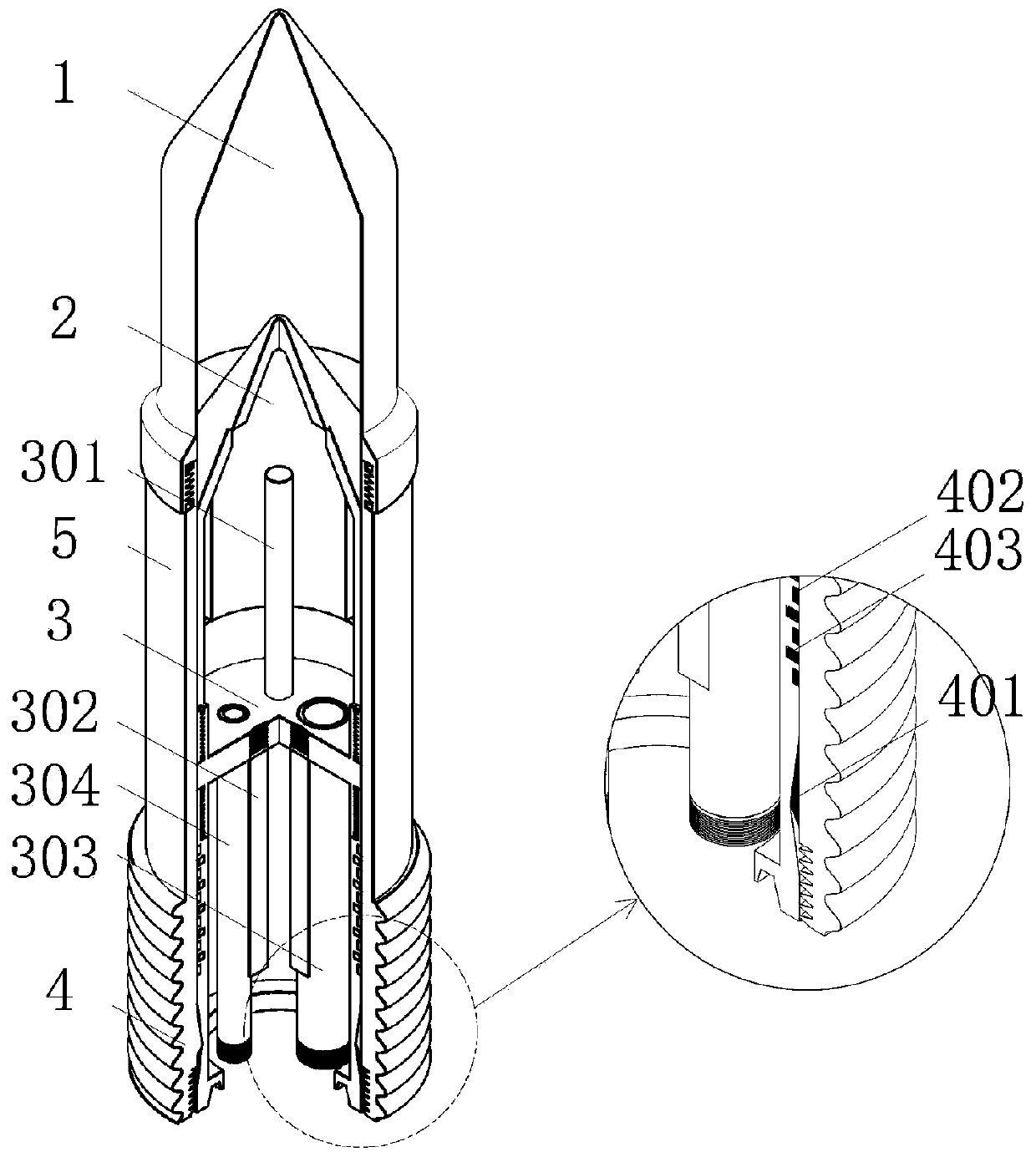

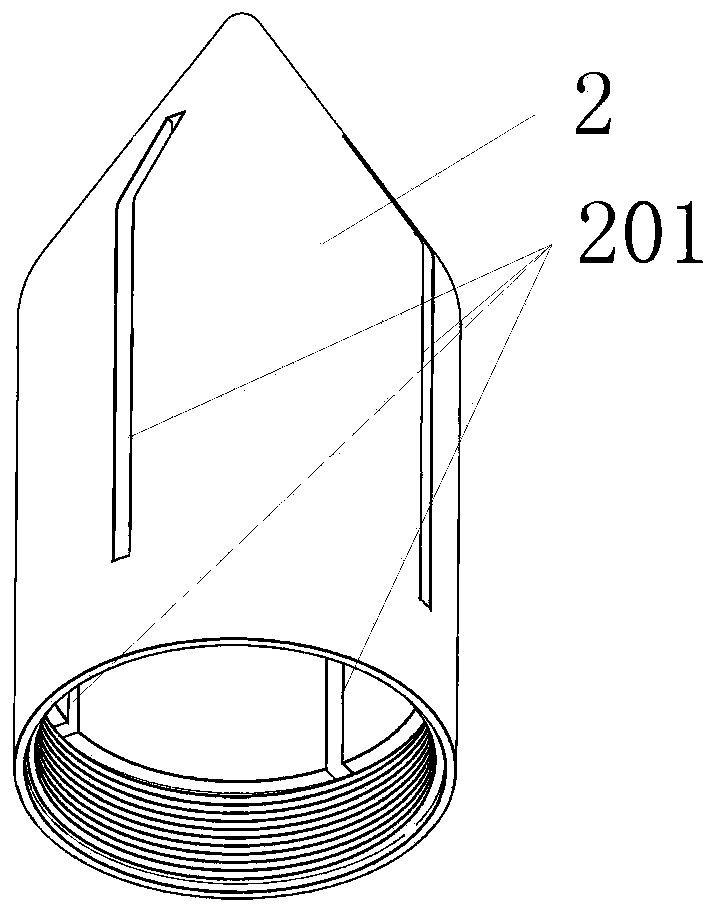

[0037] Such as figure 1 As shown, the earth pressure measuring device outside the shield tunnel of the present invention includes a TPU oil bag 1, the "upper" part 2 of the piston, a set pair wire 3, a heating rod 301, a pressure liquid level set temperature transmitter 302, an oil delivery pipe 303, Exhaust pipe 304, stainless steel cylinder 4, water-expandable rubber sleeve 5, piston "lower" part 6, silicone O-ring 7, piston installation support part 8, earth pressure measurement device installation support part 9.

[0038] The main function of the TPU oil bladder 1 is to sense the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com