Full automatic titrimeter applied to volumetric method titration and working method thereof

A fully automatic and titrator technology, which is applied in the direction of instruments, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. End-point discrimination bias and other issues, to achieve the effect of facilitating promotion and application, eliminating interference and human bias, and accurate color recognition results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

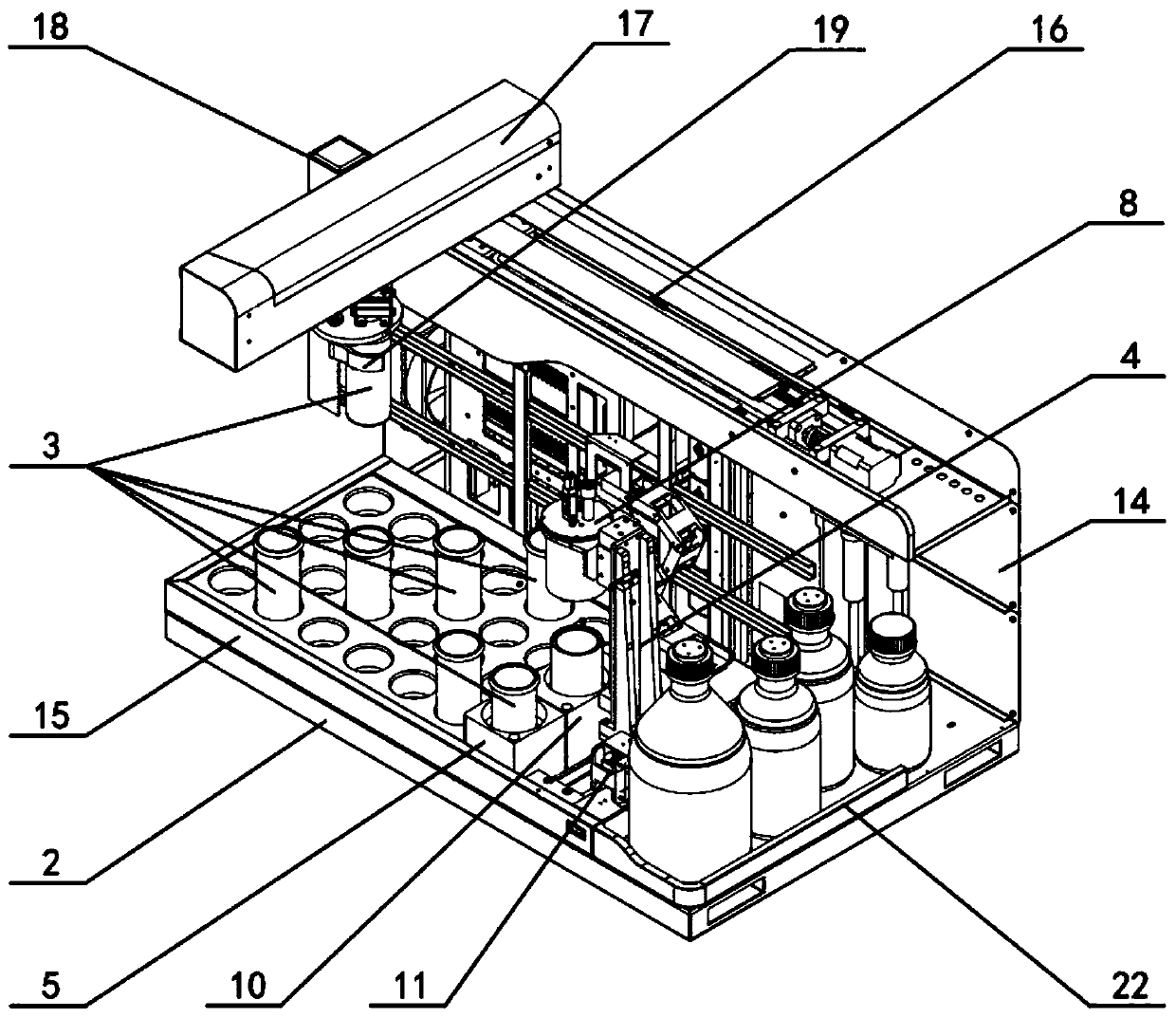

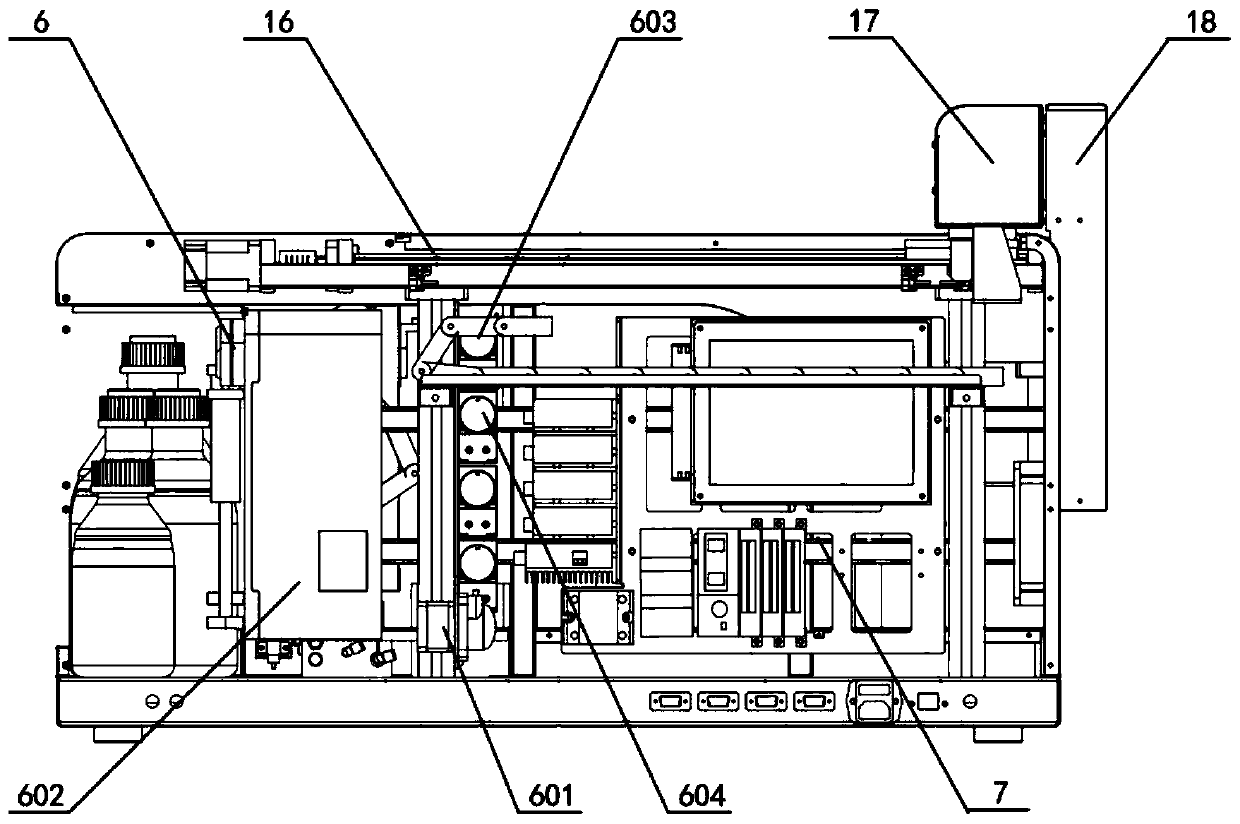

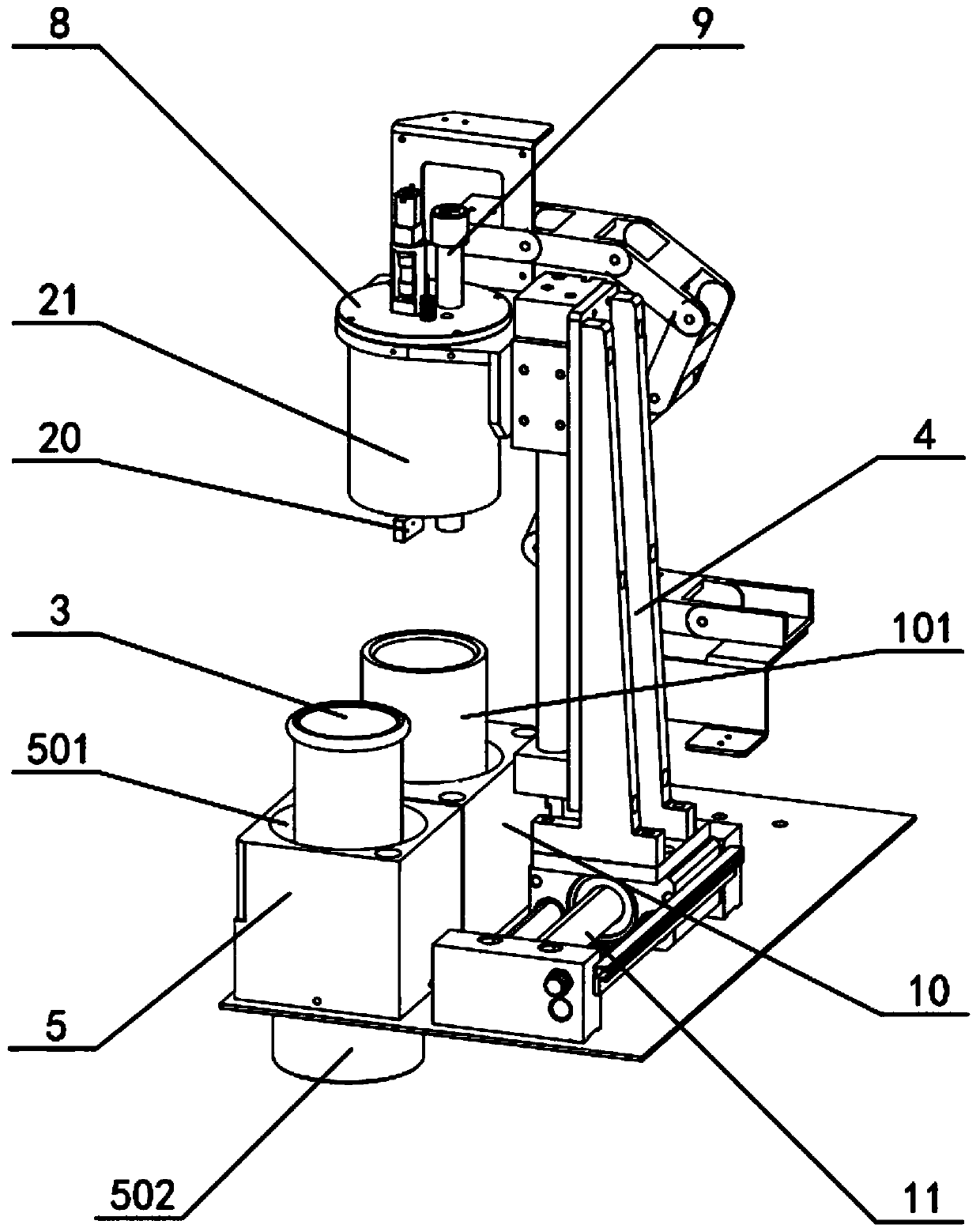

[0064] Such as Figure 1-8 As shown, the full-automatic titrator for volumetric titration provided in this embodiment includes a host computer, a base mounting plate 2 and several transparent test cups 3, and first Lifting mechanism 4, titration work position 5, pump body mounting frame 6 and control panel mounting frame 7; on the lifting part of the first lifting mechanism 4, a lifter that can be lifted directly above the titration work position 5 is fixedly installed. The titration mechanism mounting plate 8 is provided with a test cup placement groove 501 for placing the test cup 3 on the top surface of the titration work position 5, and a white light for shining upward is installed at the bottom of the test cup placement groove 501. The emission source 502 is equipped with a peristaltic pump 601, a syringe pump 602, and a switching valve for switching between pumping / injecting channels on the pump body mounting frame 6, and a control host is installed on the control board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com