A kind of dental alginate impression material and its preparation method

A dental alginate and impression material technology, which is applied in the fields of dental impression materials, dental preparations, dentistry, etc., can solve the problems of difficult mixing, increasing the difficulty of dentist operation, affecting the accuracy of impression taking, etc., and reaching the working time Sufficient, not easy to be bitten through, and convenient for doctors to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

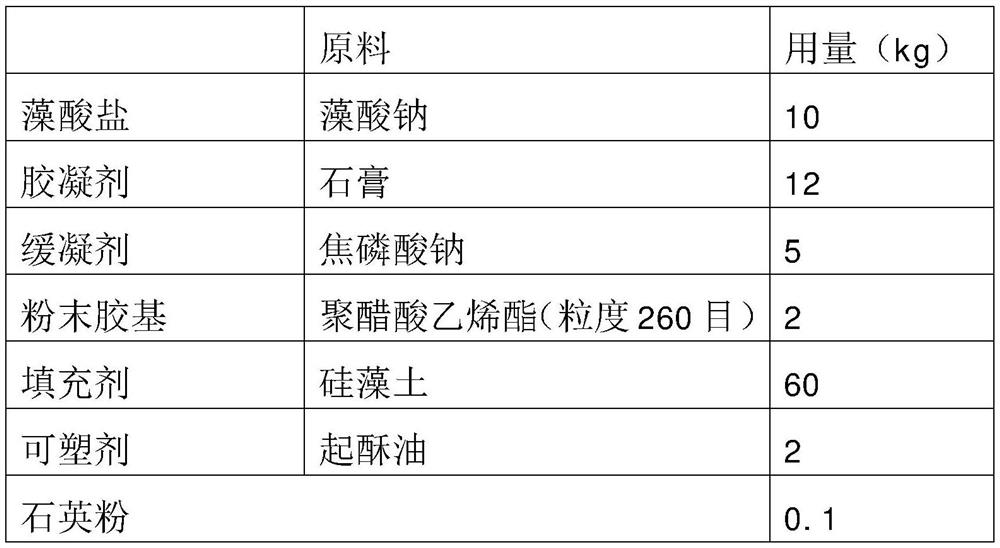

[0045] See Table 1 for the raw material composition and proportion of the impression material provided in Example 1.

[0046] The preparation method of the impression material provided in Example 1 is as follows:

[0047] Oil-soil mixing: Premix the plasticizer liquid paraffin and part of the filler diatomaceous earth in a mass ratio of 1:5 for 15 minutes according to the proportioning in Table 1 to obtain the oil-soil mixture;

[0048] Clay mixing: premix powdered gum-based polyvinyl acetate (260 meshes) and part of the filler diatomaceous earth in a mass ratio of 1:5 for 15 minutes to obtain a clay mixture;

[0049] Mixing: Mix the oil-soil mixture and the clay mixture, add the remaining filler and other raw materials, and mix for 15 minutes at a stirring speed of 200r / min to obtain the alginate impression material.

[0050] Raw material composition and proportioning of table 1 embodiment 1

[0051] raw material Dosage(kg) alginate sodium alginate 18 ...

Embodiment 2

[0053] The raw material composition and proportioning of the impression material provided in Example 2 are shown in Table 2, and the preparation method is the same as in Example 1.

[0054] Raw material composition and proportioning of table 2 embodiment 2

[0055] raw material Dosage(kg) alginate sodium alginate 15 gelling agent plaster 8 retarder sodium pyrophosphate 2 Powdered Gum Base Polyvinyl acetate (particle size 260 mesh) 1 filler diatomite 73 plasticizer liquid paraffin 2

Embodiment 3

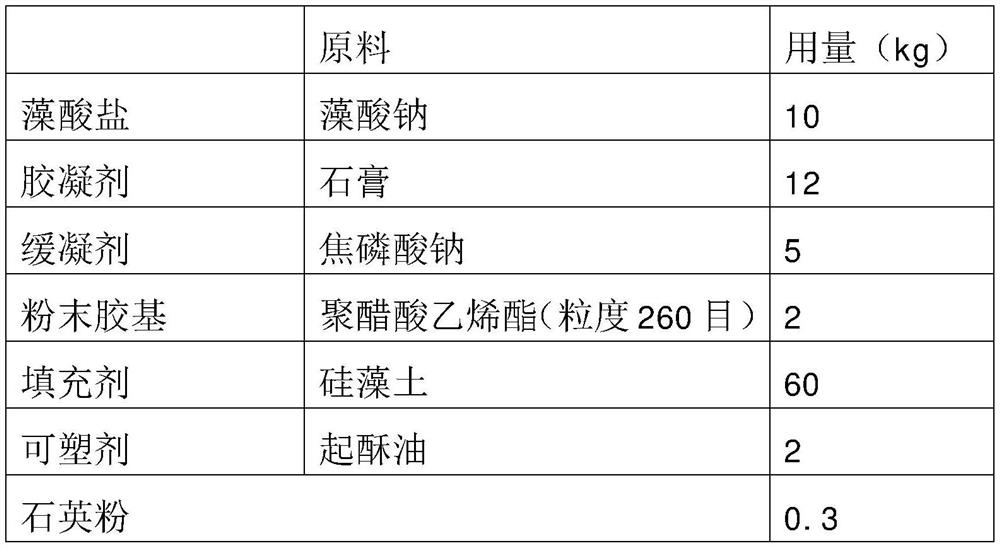

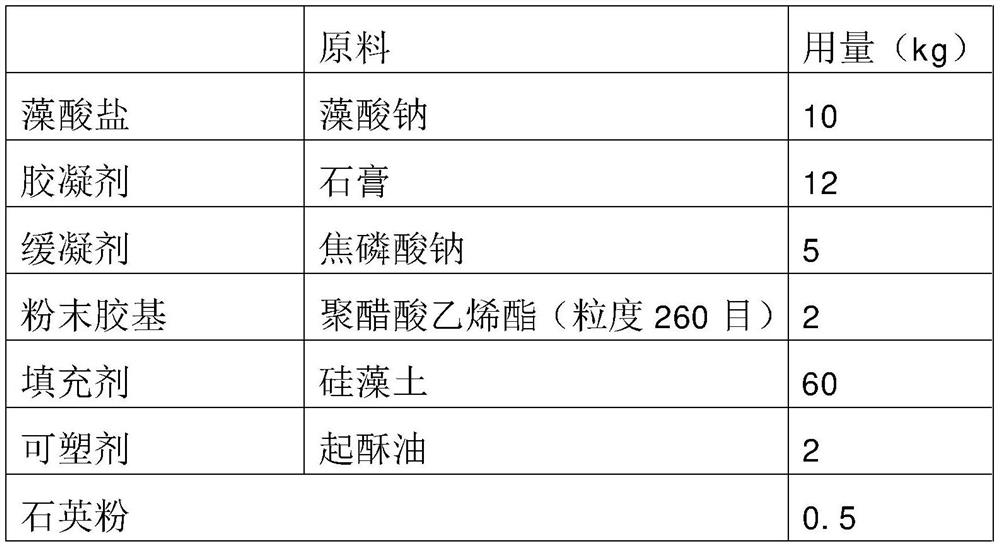

[0057] The raw material composition and proportioning of the impression material provided in Example 3 are shown in Table 3, and the preparation method is the same as in Example 1.

[0058] Raw material composition and proportioning of table 3 embodiment 3

[0059] raw material Dosage(kg) alginate sodium alginate 10 gelling agent plaster 12 retarder sodium pyrophosphate 2 Powdered Gum Base Polyvinyl acetate (particle size 260 mesh) 1 filler diatomite 73 plasticizer liquid paraffin 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap