Pipe fitting seal ring assembling machine

A sealing ring, assembly machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low operation efficiency, difficult to pass pipe fittings, high labor intensity, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

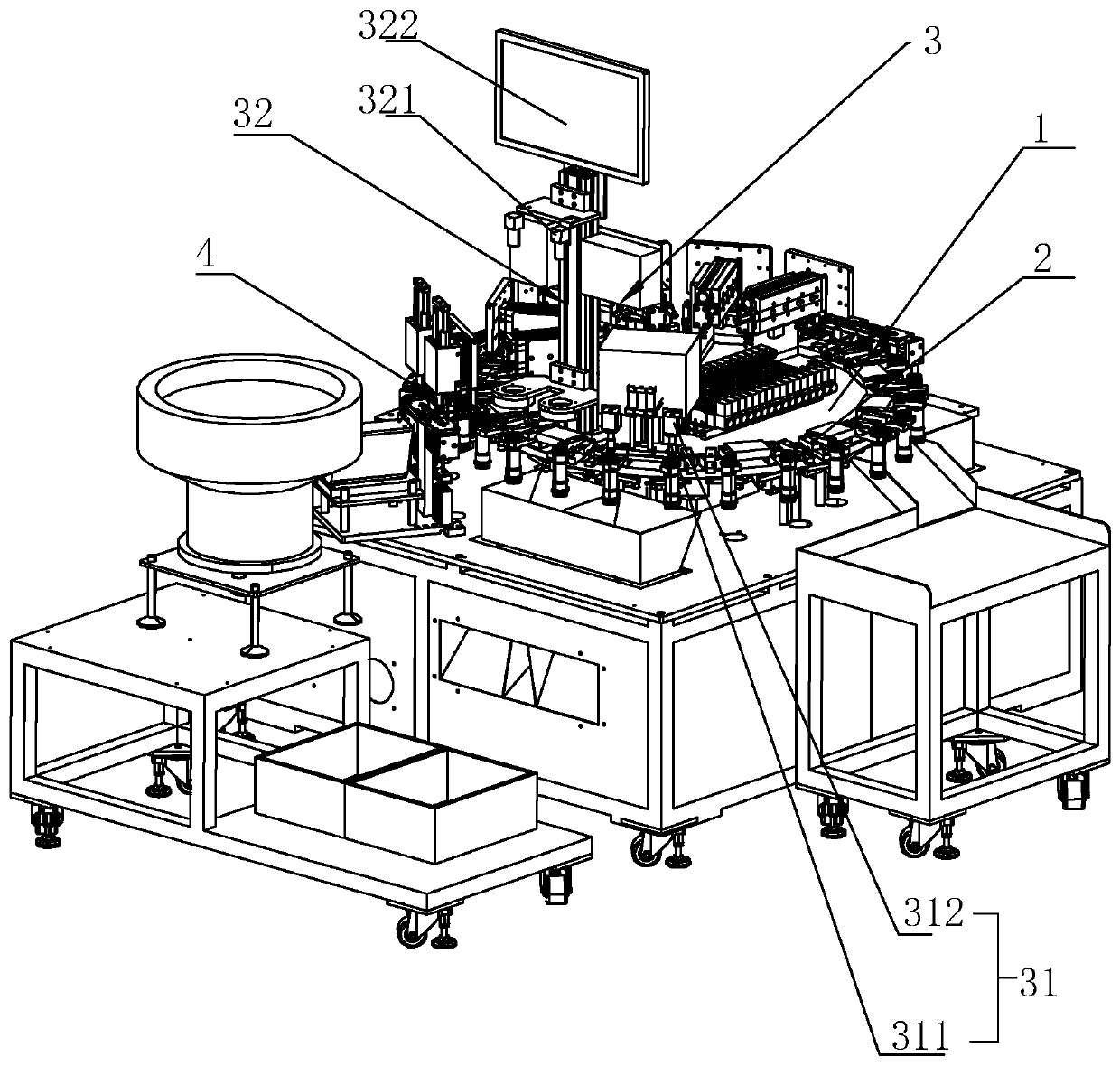

[0028] Refer to attached Figure 1 to Figure 5 The embodiment of a sealing ring assembly machine for pipe fittings of the present invention will be further described in detail.

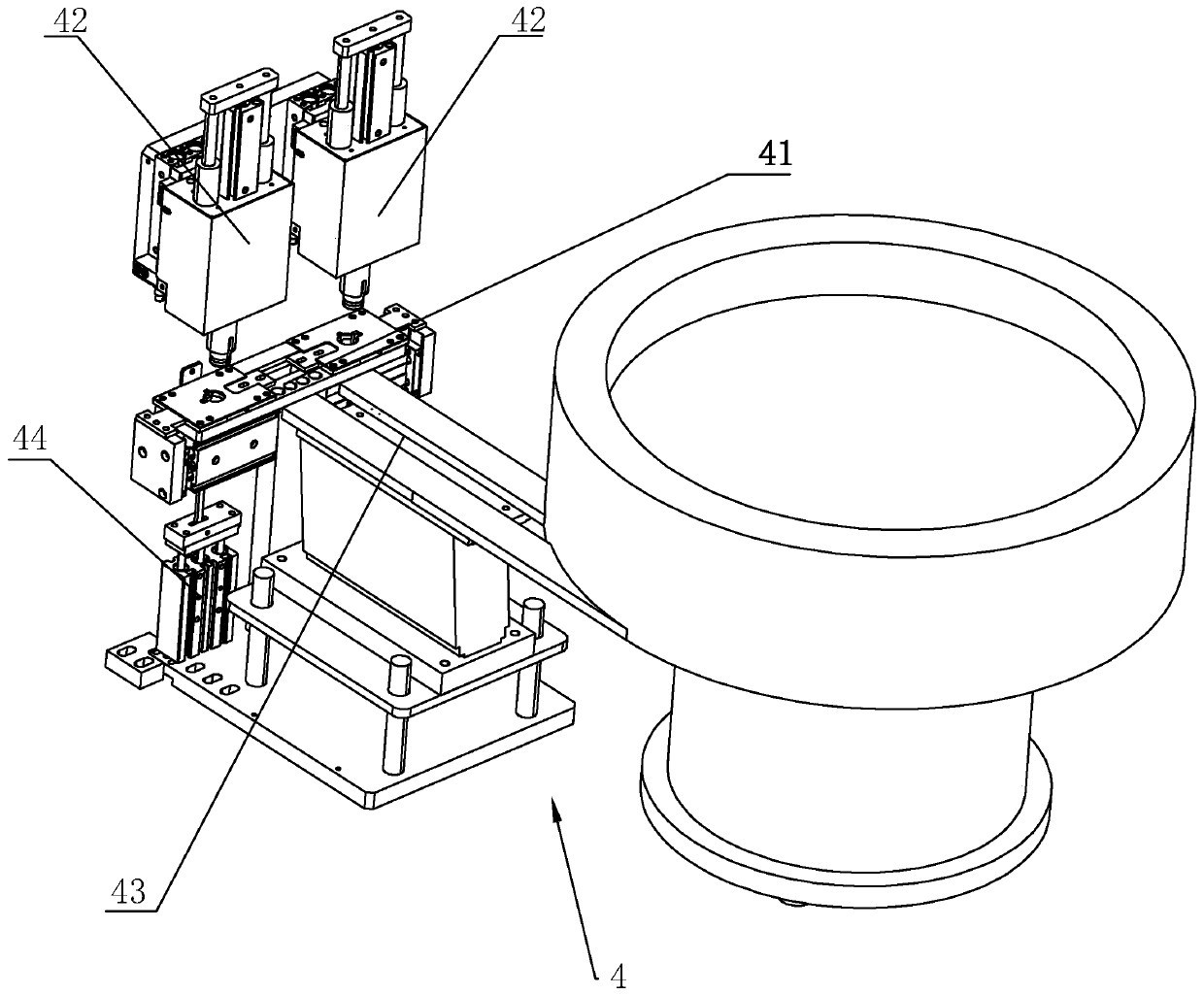

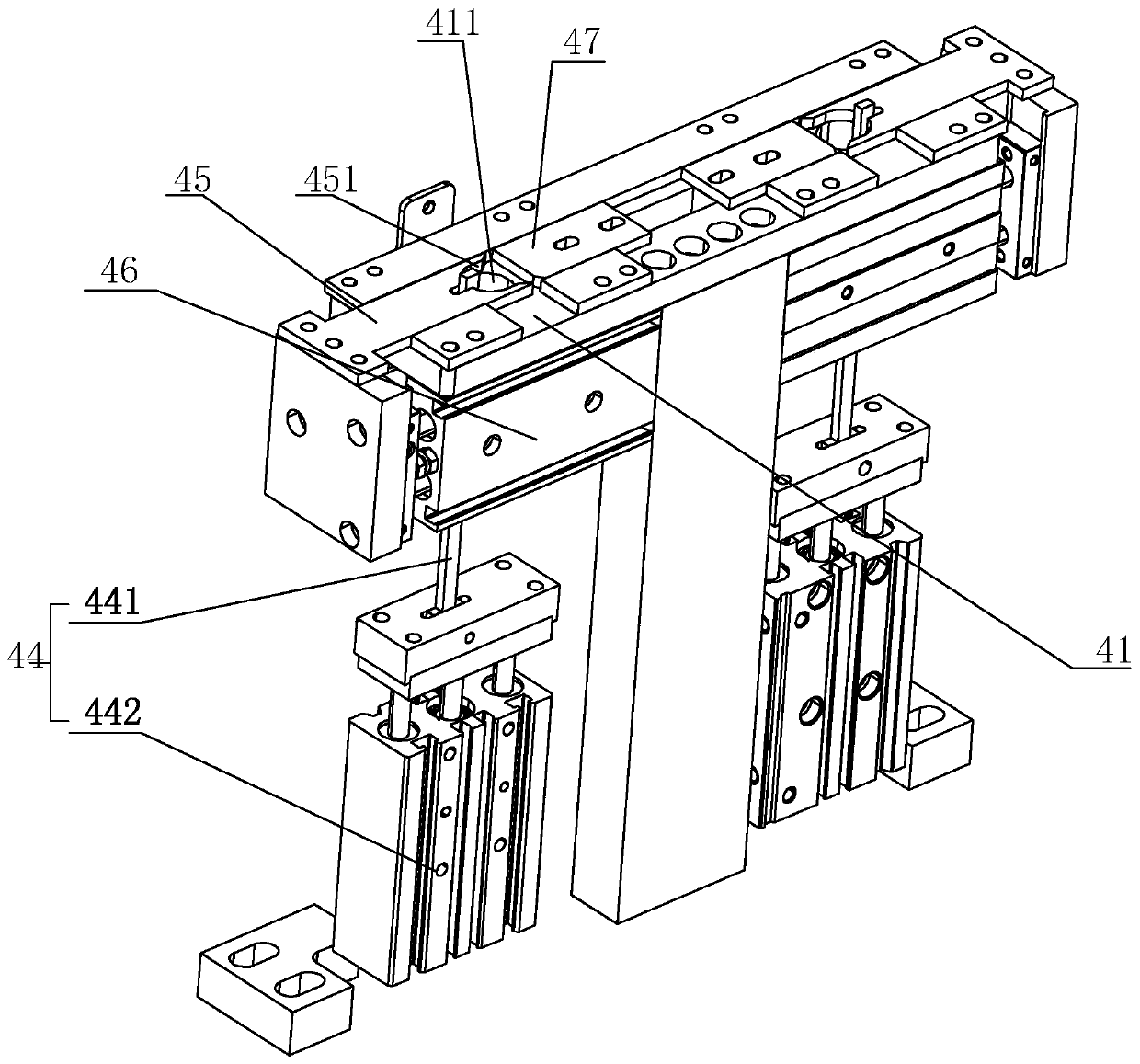

[0029] A pipe sealing ring assembly machine, including an assembly platform 1 and an assembly driver that drives the assembly platform 1 to rotate, on the edge of the assembly platform 1, several clamping manipulators 2 for clamping pipe fittings are arranged; on one side of the assembly platform 1 An inspection mechanism 3 for inspecting the manufacturing dimensions of the pipe fittings and a sealing ring retrieving and assembling mechanism 4 for assembling the sealing ring on the pipe fittings are provided; the inspection mechanism 3 includes a general gauge detection station 31 for the inner diameter of the pipe fitting socket and inspection of the pipe fitting socket The visual inspection station 32 of the inner diameter and the outer diameter of the socket is provided with unqualified collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com