Cooling water jacket

A cooling water jacket and waterway technology, applied in the field of cooling water jacket, can solve the problems of lowering the temperature of the needle valve area, stagnant water in the cooling water jacket, disadvantages, etc., and achieve the effect of improving product quality and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

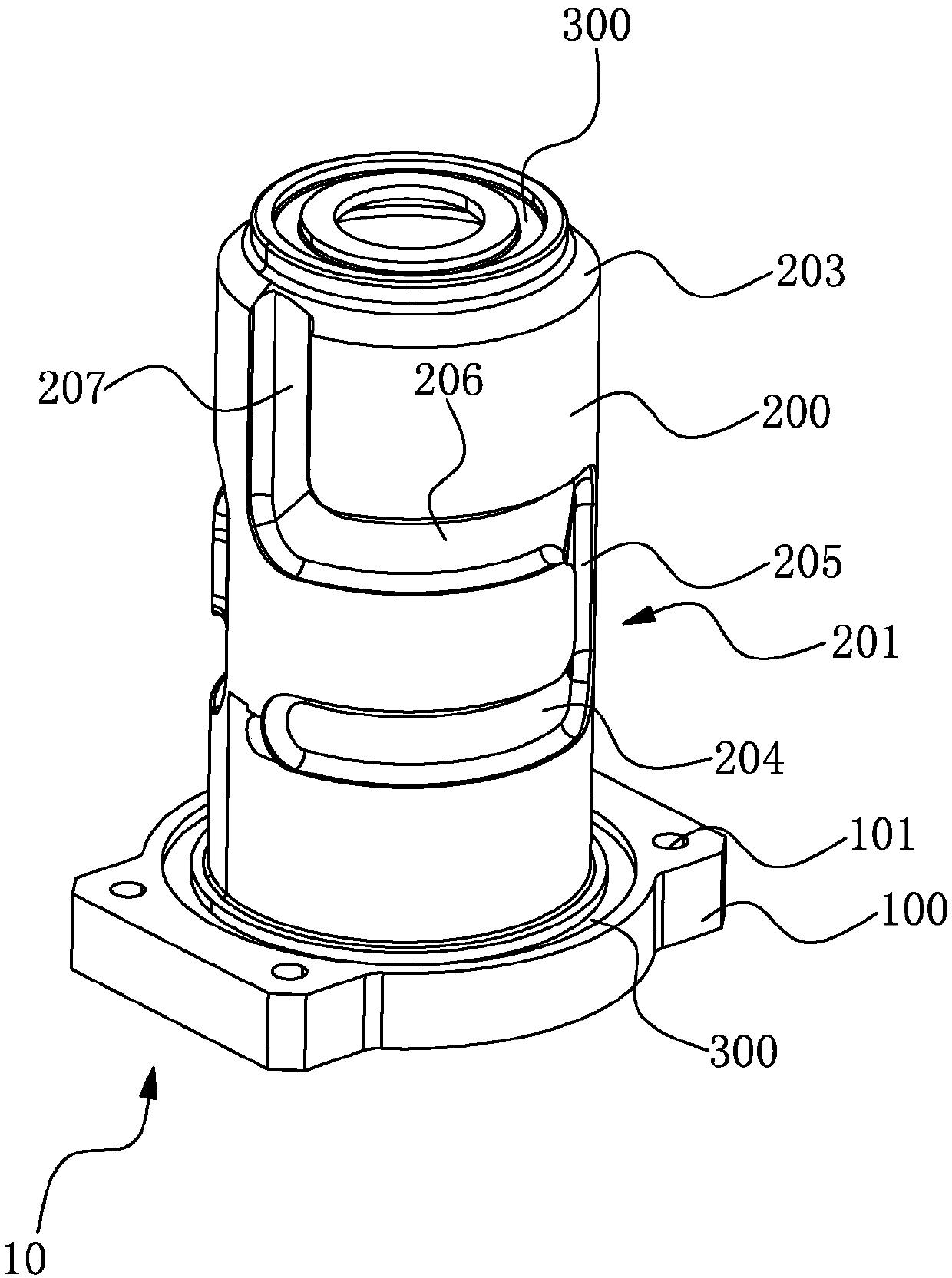

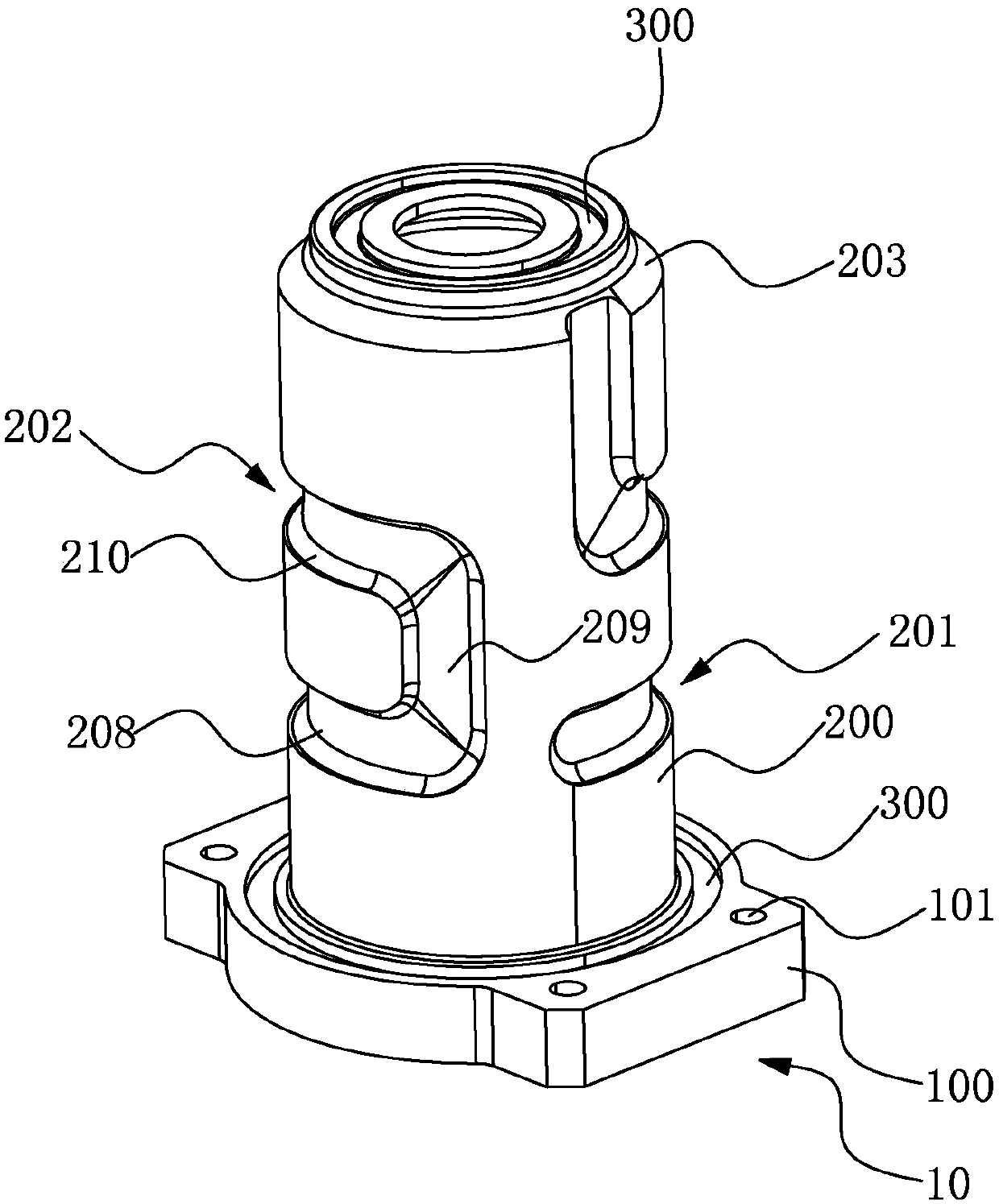

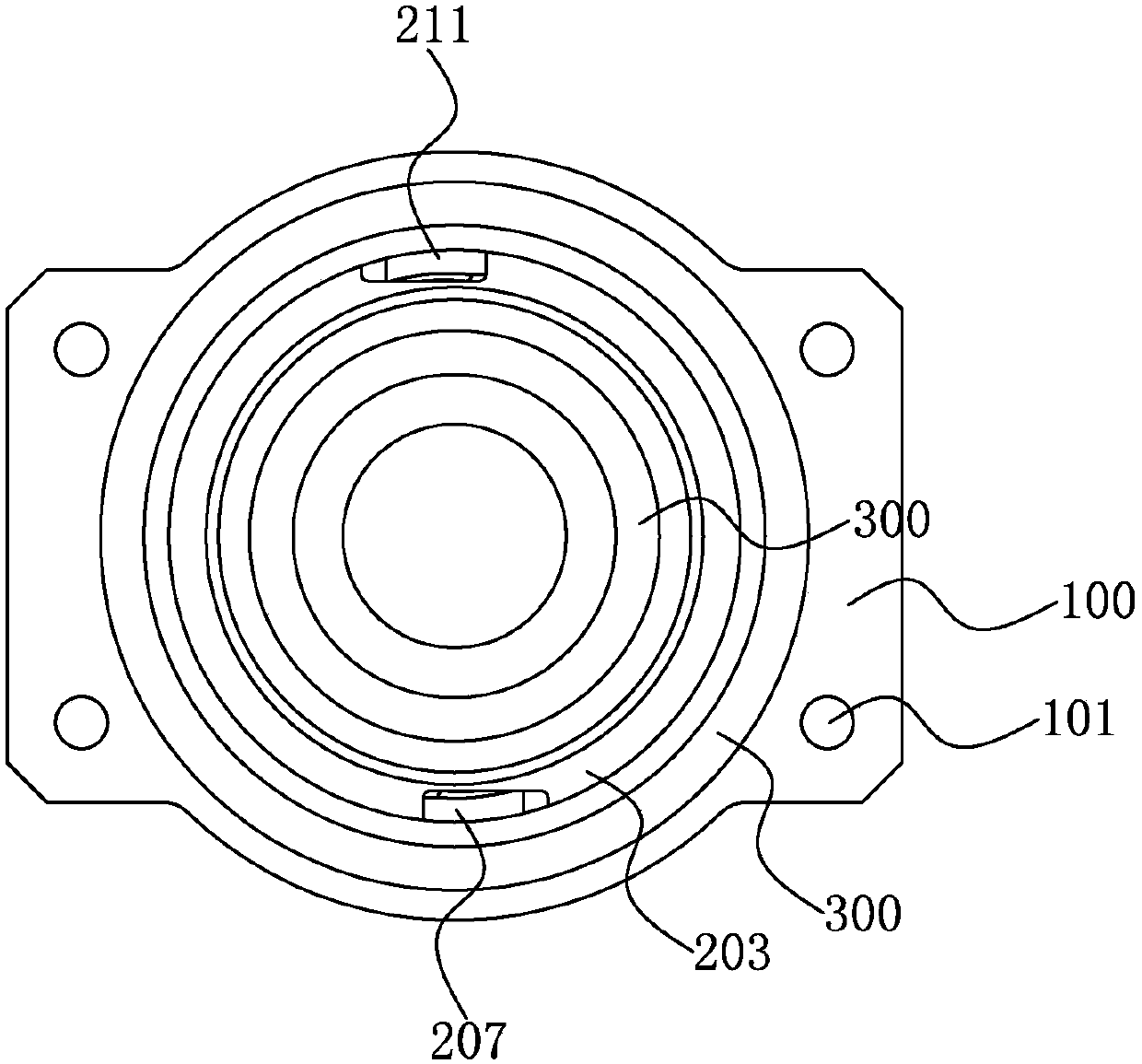

[0025] see Figure 1 to Figure 3 shown, where figure 1 A schematic diagram illustrating an angle of the cooling water jacket of the present invention, figure 2 A schematic diagram illustrating another angle of the cooling water jacket of the present invention, image 3 A top view of the cooling water jacket of the present invention is shown.

[0026] In this embodiment, the cooling water jacket 10 of the present invention is applied in a mold, and the cooling water jacket 10 includes:

[0027] The fixing part 100 is fixed on the formwork of the mould, thereby fixing the cooling water jacket 10 on the formwork of the mould;

[0028] The main body part 200 is set on the hot nozzle to cool the hot nozzle. The main body part 200 is provided with a cooling water path for the cooling liquid to flow in the main body part. The cooling liquid can be liquid water, and the cooling water path has a rising Waterway 201, descending waterway 202 and arc-shaped waterway 203, the ascendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com