Washing Drainage Piping System

A technology for drainage pipes and washing water, which is applied in washing devices, other washing machines, textiles and paper making, etc., can solve the problems of inconvenient and flexible placement or installation, high height and large size of dishwashers, and achieves the solution to the problem of over-occupancy, Solve the effect of inconvenient installation and flexible location settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

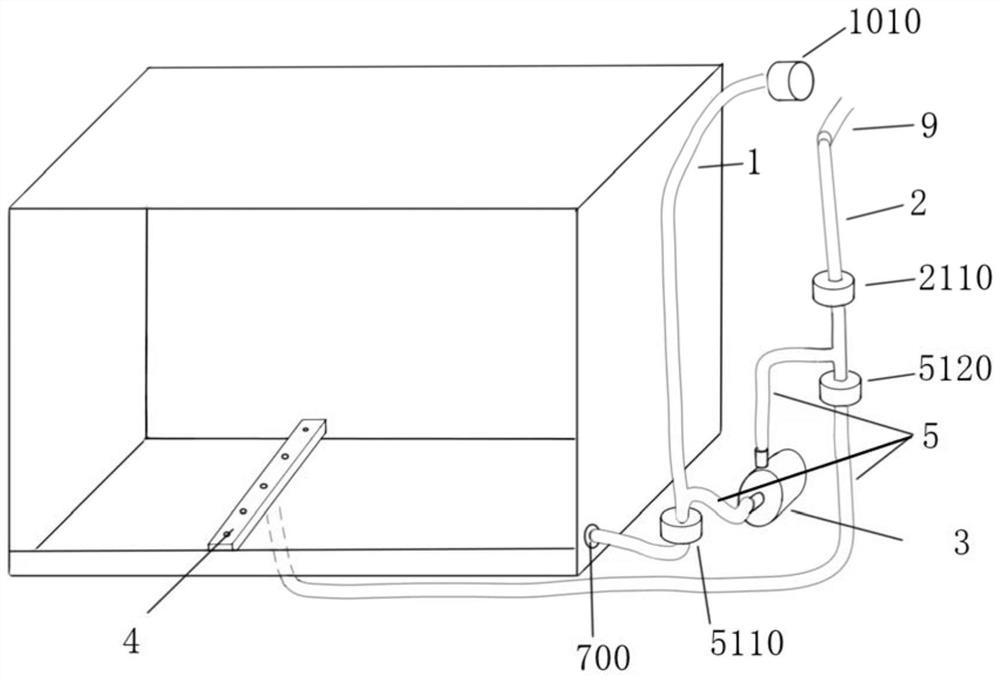

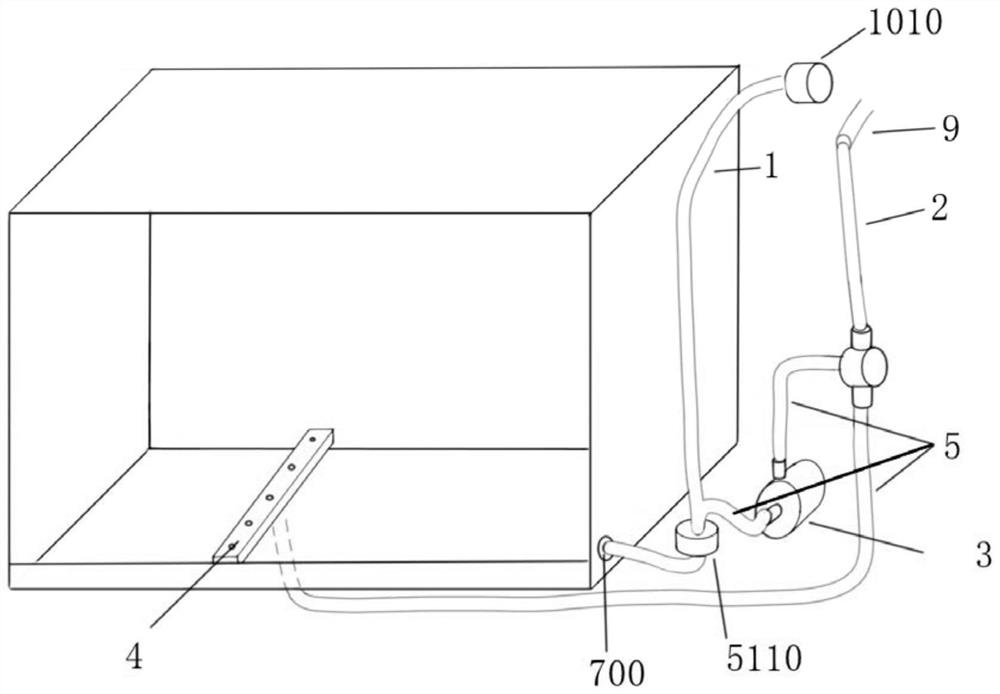

[0020] Example 1 as figure 1 As shown, the drainage part includes a single drainage port 700, and the right side of the inner tank is equipped with a washing circulation passage 5, a water inlet pipeline 1, a drainage pipeline 2, a washing pump 3, a nozzle 4, a water inlet valve 1010 and an isolation valve 2110.

[0021] The two ends of the washing circulation path 5 are respectively connected to the nozzle 4 and the drain port 700 of the drainage part, the washing pump 3 is controlled to be connected to the washing circulation path 5, the water inlet of the washing pump 3 is connected to the drain port 700, and the outlet of the washing pump 3 is connected to the Said spray pipe 4; water inlet valve 1010 controls water inlet pipeline 1 to be connected on the pipeline between the washing pump of washing circulation passage 5 and the drain port 700; On the position between the pump and the nozzle 4.

[0022] The bottom valve 5110 adopts a one-way valve, and the water flow can...

Embodiment 2

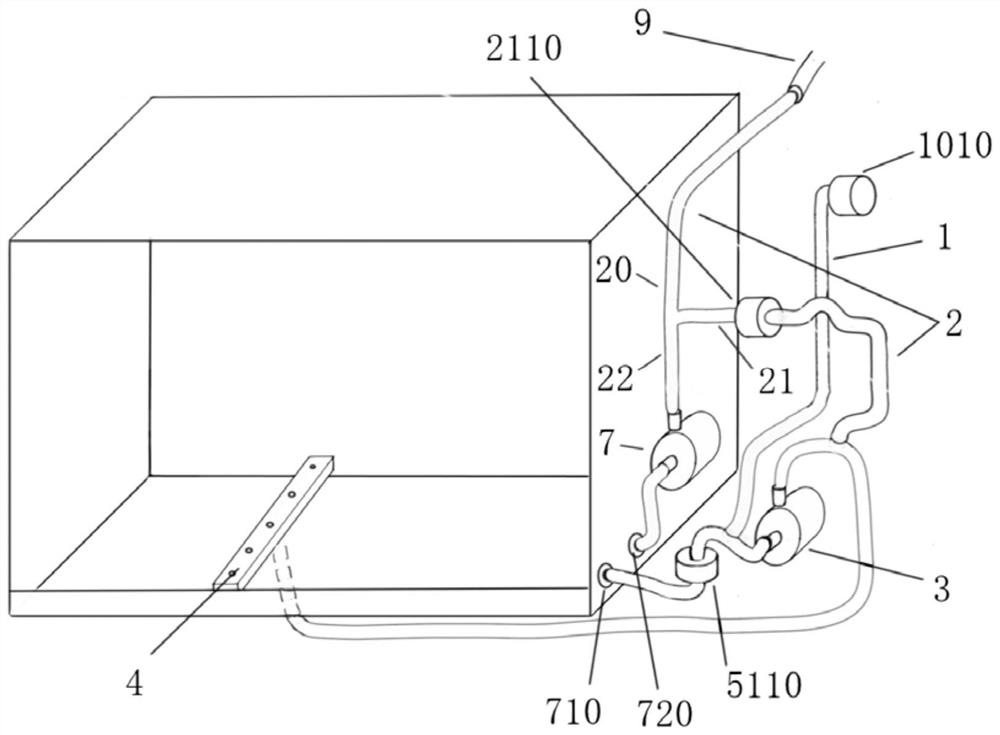

[0028] Embodiment 2 is attached image 3 As shown, on the basis of Embodiment 1, the drainage part is subdivided into a washing water discharge part 710 and a waste water discharge part 720 . The drainage pipeline 2 has increased the connecting pipeline to the waste water discharge part 720, and like this, the drainage pipeline 2 is divided into three parts, the main drainage section 20 connected to the external drainage pipe 9, and the section connected to the washing cycle passage with an isolation valve 2110. The first connection section 21 and the second connection section 22 connected to the waste water discharge part 720 are provided with a drainage pump 7 . The washing pump 3 is controlled to be connected to the washing water discharge part 710 through the bottom valve 5110 .

[0029] When the water enters, because of the blocking of the bottom valve 5110, all the water will be injected into the washing pump 3, and flow into the inner tank through the nozzle; Liner. ...

Embodiment 3

[0033] Example 3 as Figure 4 As shown, on the basis of Example 2, further, a bottom valve box 6110 is added to the bottom of the dishwasher liner. In addition, for the convenience of installation, the installation method of the water inlet pipeline 1 is changed to the first one of the drainage pipeline 2. The connecting section is also connected to the position between the washing pump 3 and the spray head 4 of the washing circulation passage 5 .

[0034] The bottom valve box 6110 is equipped with a bottom valve 5110 and a water level sensor 6120. The bottom valve 5110 adopts a one-way valve, and the water flow can only flow from the bottom valve box to the washing pump 3, but not in the reverse direction; the water level sensor 6120 adopts a float type water level switch . The inlet of the washing pump 3 is connected to the bottom valve 5110 through the hole at the top of the bottom valve box 6110, and the outlet of the washing pump 3 is connected to the spray pipe 4 inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com