Papermaking pulp mill with good milling effect

A refiner and refining technology, which is applied in the field of papermaking equipment and refiners, can solve the problems of low degree of fiber refinement and uneven refining, and achieve the effect of good pulp quality and high degree of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

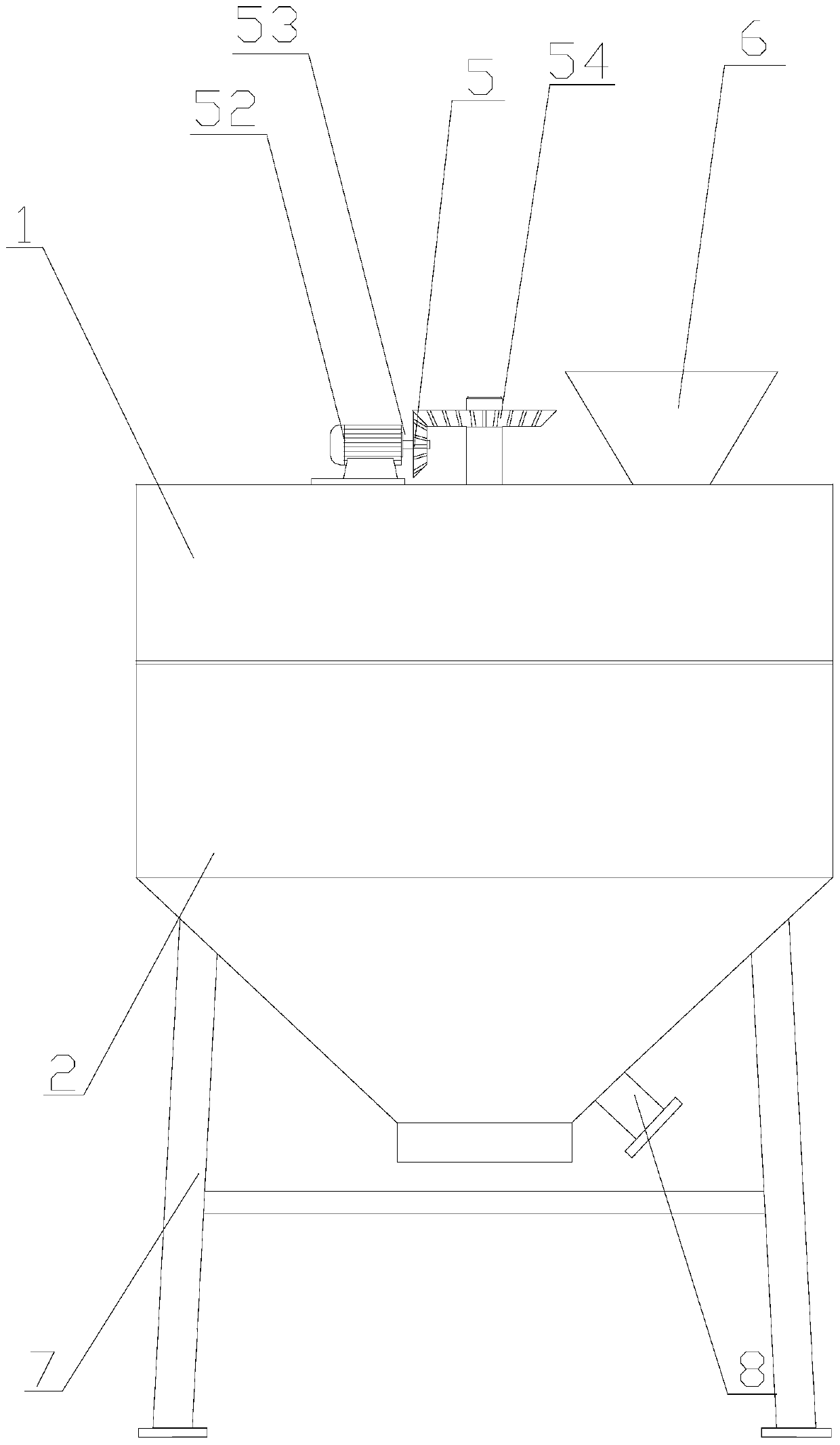

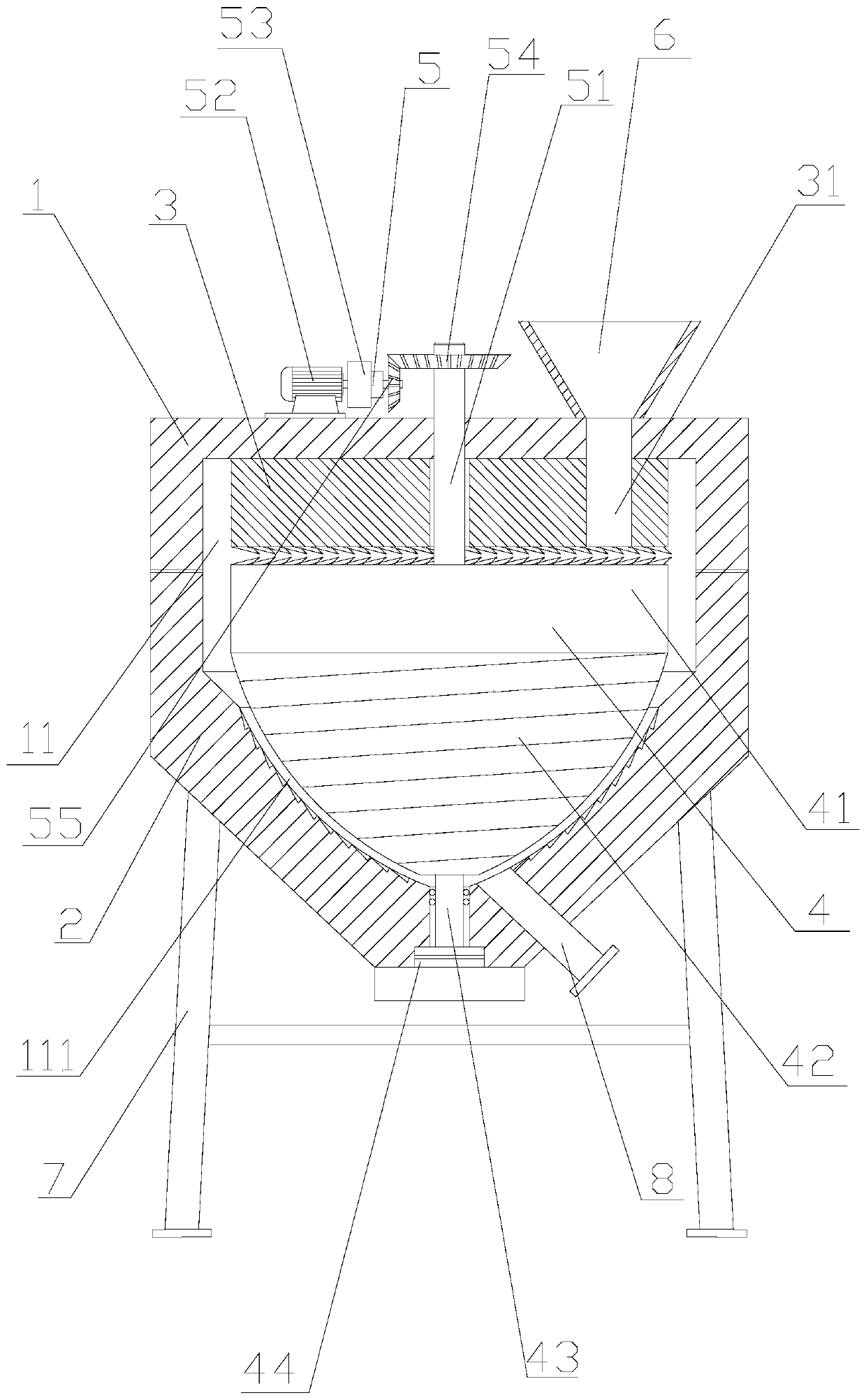

[0017] refer to figure 1 and figure 2 , a refiner with good refining effect for papermaking in the present invention, comprising a refiner upper housing 1, a refiner lower housing 2, a fixed grinding disc 3, a moving grinding disc 4, a driving mechanism 5, a feed hopper 6, several Support legs 7, discharge port 8, the lower end of the refiner upper shell 1 is provided with a refiner lower shell 2, and the refiner upper shell 1 and the refiner lower shell 2 are detachable connection, the upper housing 1 of the refiner and the lower housing 2 of the refiner cooperate with each other to provide a refining chamber 11, and the upper end of the refining chamber 11 is provided with a fixed grinding disc 3, and the fixed grinding disc The upper end of 3 is fixedly connected with the upper housing 1 of the refiner, the lower end of the fixed grinding disc 3 is provided with a movable grinding disc 4 that can cooperate with it, and the lower end of the movable grinding disc 4 is rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com