Micro flow and ultrafine flow measuring device and method

A flow measurement and micro-flow technology, which is applied in the field of performance detection of ultra-micro flow output devices, can solve the problems such as the inability to meet the requirements of ultra-micro flow measurement, the difficulty in guaranteeing the accuracy of ultra-micro flow meters, and the inability to meet the requirements. High accuracy, high repeatability, the effect of improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail in conjunction with the following specific embodiments and accompanying drawings. The process, conditions, experimental methods, etc. for implementing the present invention, except for the content specifically mentioned below, are common knowledge and common knowledge in this field, and the present invention has no special limitation content.

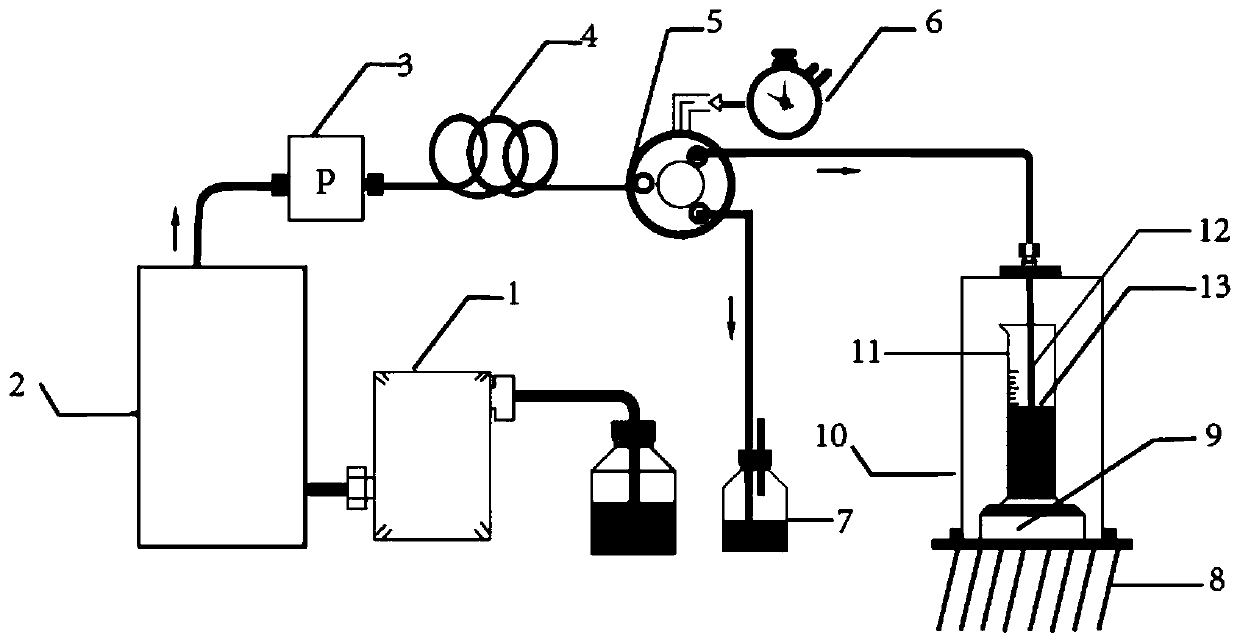

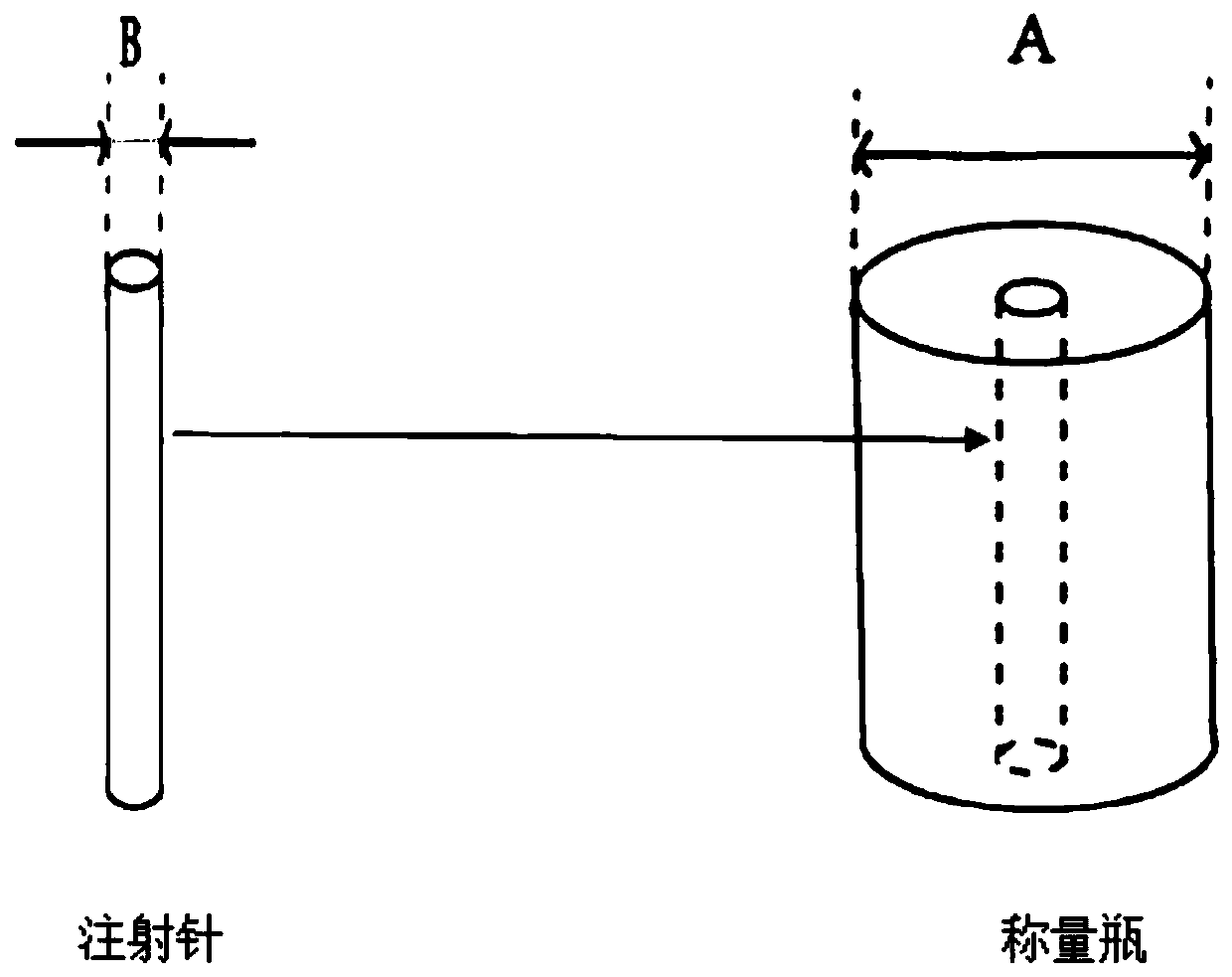

[0028] Figure 1-Figure 2 Medium, 1-vacuum degasser, 2-tested infusion pump, 3-pressure sensor, 4-damping tube, 5-high-pressure electric switching valve, 6-high precision timer, 7-waste liquid bottle, 8-high stability Weighing platform, 9-precision electronic balance, 10-windproof glass frame, 11-weighing bottle, 12-precision injection needle, 13-liquid paraffin.

[0029] In the present invention, the micro-flow and ultra-micro flow measurement devices include 1-vacuum degasser, which is used to remove dissolved gas in the liquid. At normal temperature, the gas has a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com