A device and method for detecting leakage of dam insulation layer and concrete

A technology for concrete and thermal insulation layer, which is used in liquid/vacuum degree measurement for liquid tightness, marine engineering, construction, etc. It can solve the problems of complex thermal insulation layer procedures, lag in discovery and processing, and increased construction procedures and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

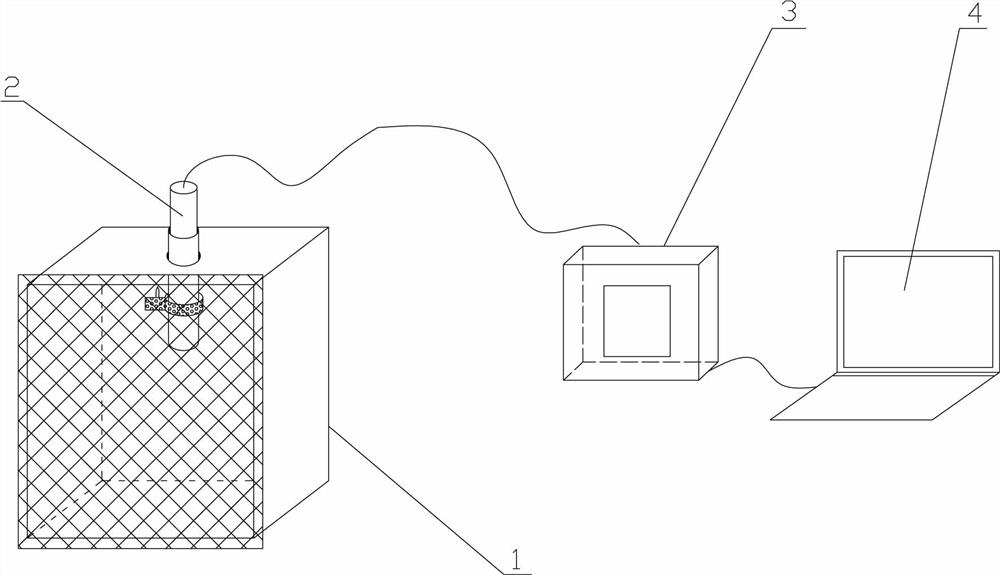

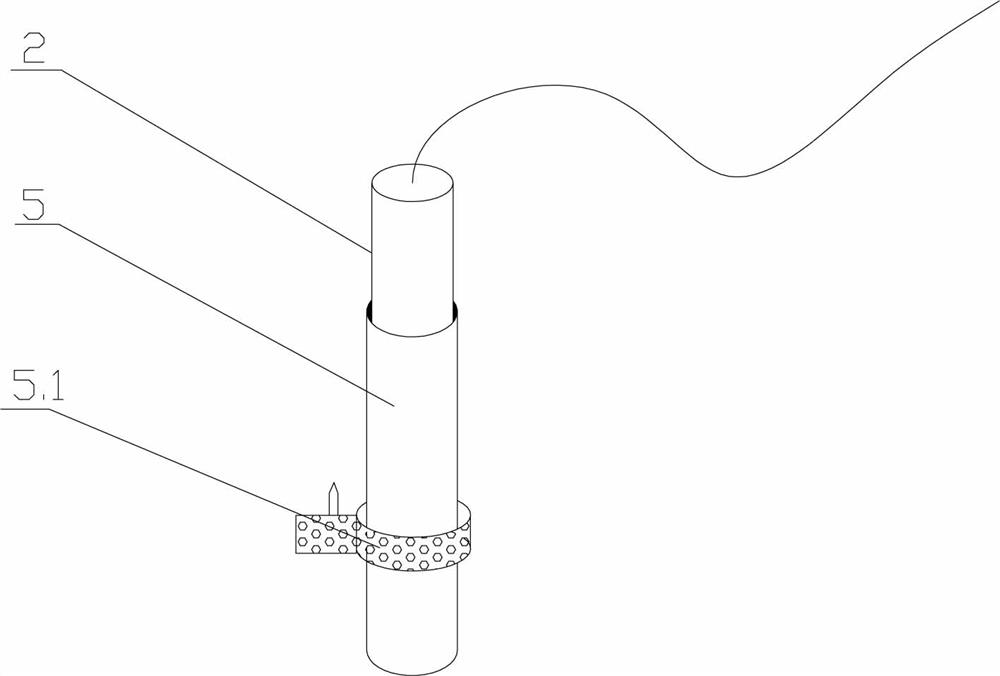

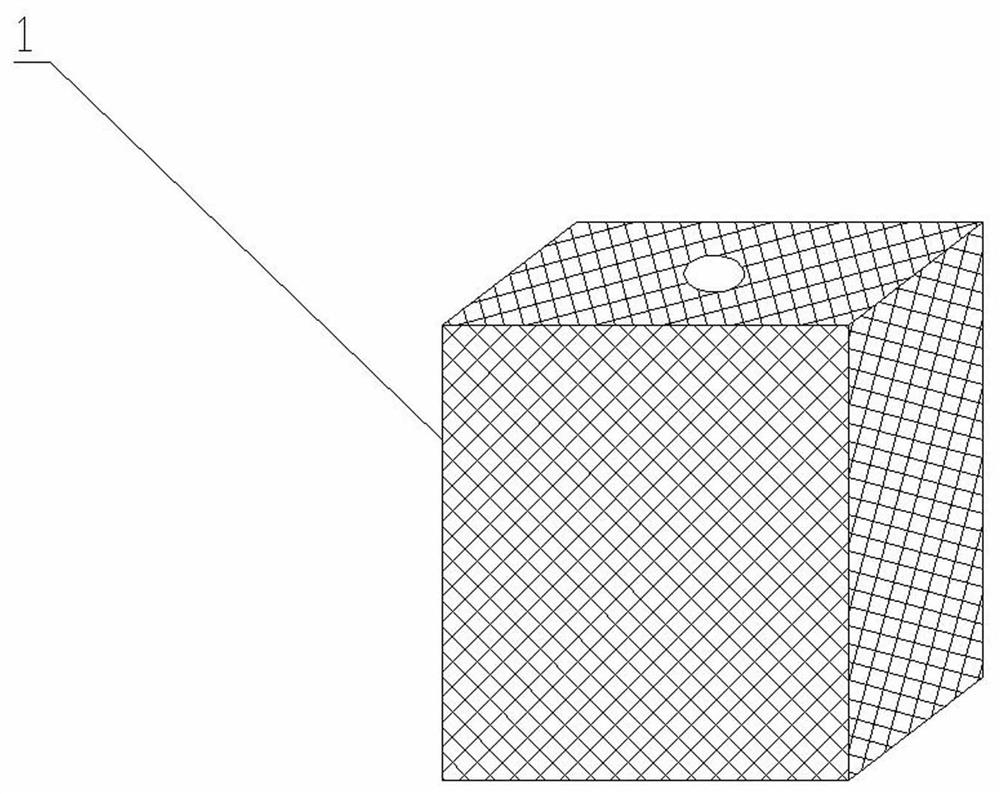

[0045] Such as Figures 1 to 4 As shown, a device for detecting dam insulation layer and concrete leakage, it includes a plurality of semi-closed protection boxes 1 arranged between the inner surface of the dam insulation layer and the outer surface of the dam concrete, the semi-closed protection boxes 1 A humidity sensor 2 is arranged inside the protective box 1 .

[0046] Preferably, the semi-enclosed protective box 1 is provided with a plurality of sieve holes near the inner surface of the dam insulation layer, and the area near the outer concrete surface of the dam is open. This design is mainly to consider that the semi-closed protection box 1 can prevent the insulation layer from being sealed to the humidity sensor 2 during construction, especially when spraying insulation materials (such as polyurethane insulation layer), afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com