Improved method for evaluating error suppression capability of CCOS polishing removal function

A technology for suppressing ability and function error, which is applied in the field of improved evaluation of CCOS polishing to remove function error suppressing ability, to achieve accurate calculation results, concise mathematical model, and reduce the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

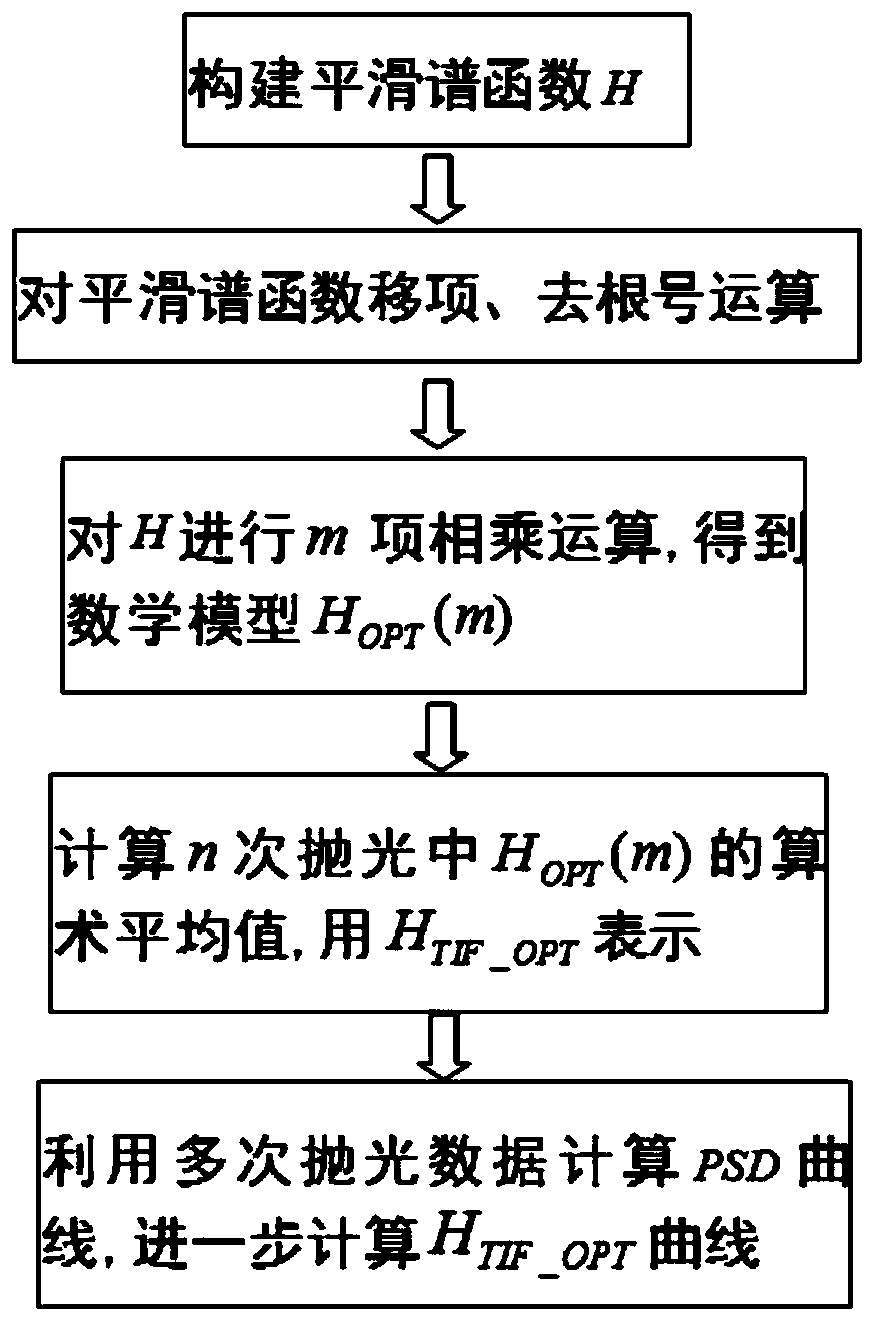

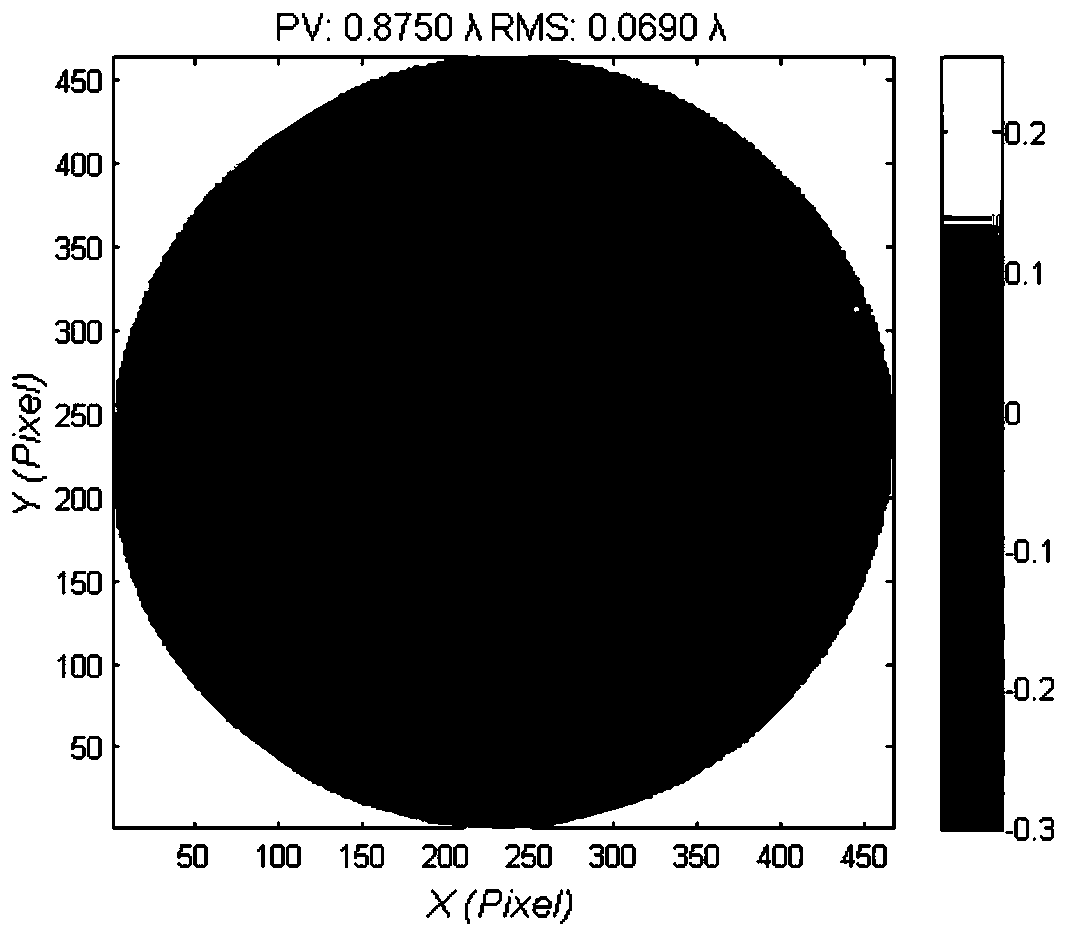

[0034] figure 1 A flow chart showing an improved method for evaluating the error suppression capability of CCOS polishing removal function error in the present invention; in this embodiment, a viscoelastic polishing disc (rigid conformal tool) is used for polishing, with a diameter of 110 mm. The optical element to be polished is a flat glass-ceramic with a diameter of φ=620mm that has been traditionally polished. The surface shape detection equipment is a 24-inch Zygo interferometer with a detection wavelength of λ=632.8nm. Applying the method of the invention to calculate the error suppression ability of the viscoelastic disc polishing.

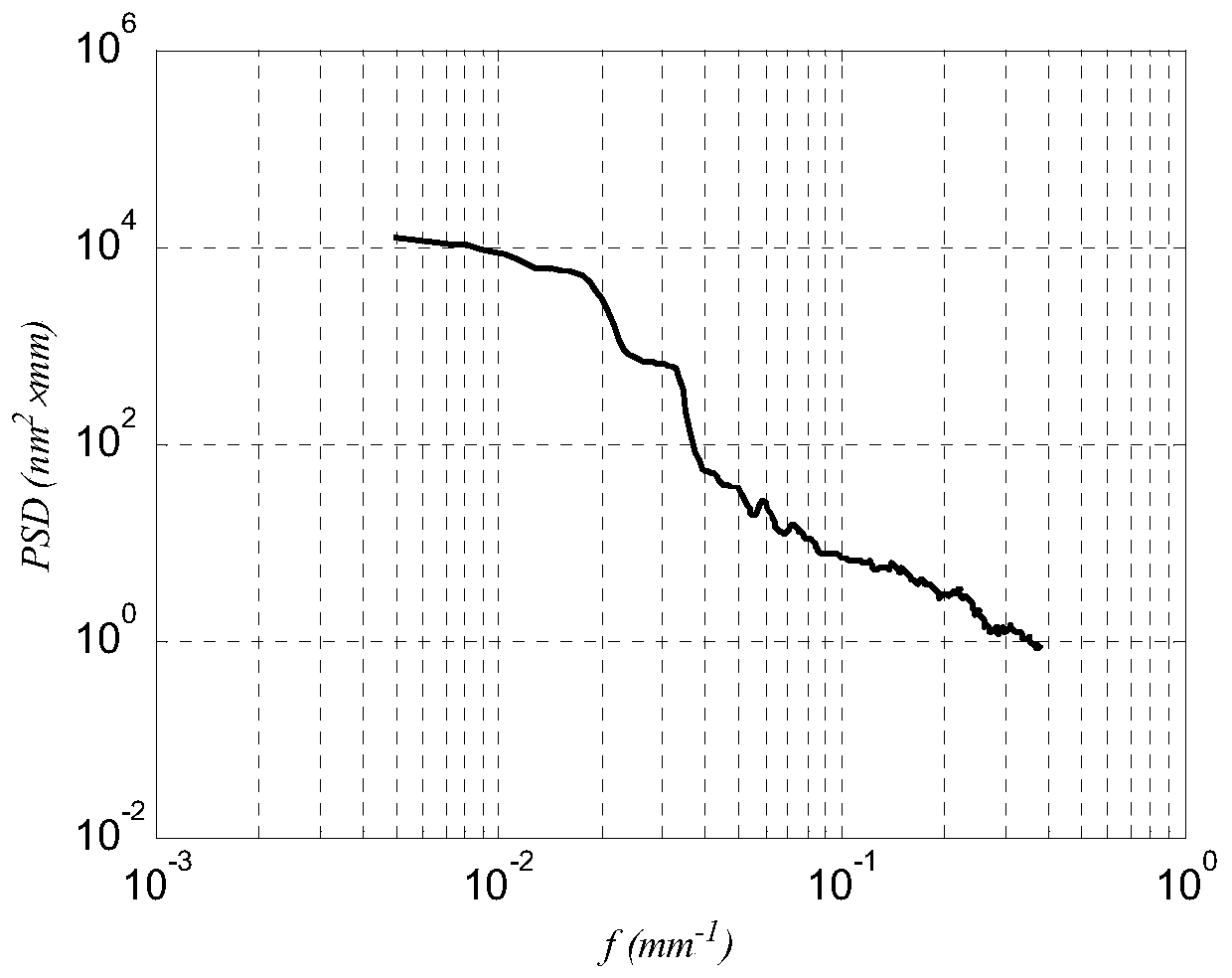

[0035] The method steps of the improved evaluation CCOS polishing removal functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com