New workpiece rescheduling optimization method based on adaptive genetic algorithm

A technology of genetic algorithm and optimization method, which is applied in the field of workpiece scheduling management in discrete manufacturing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

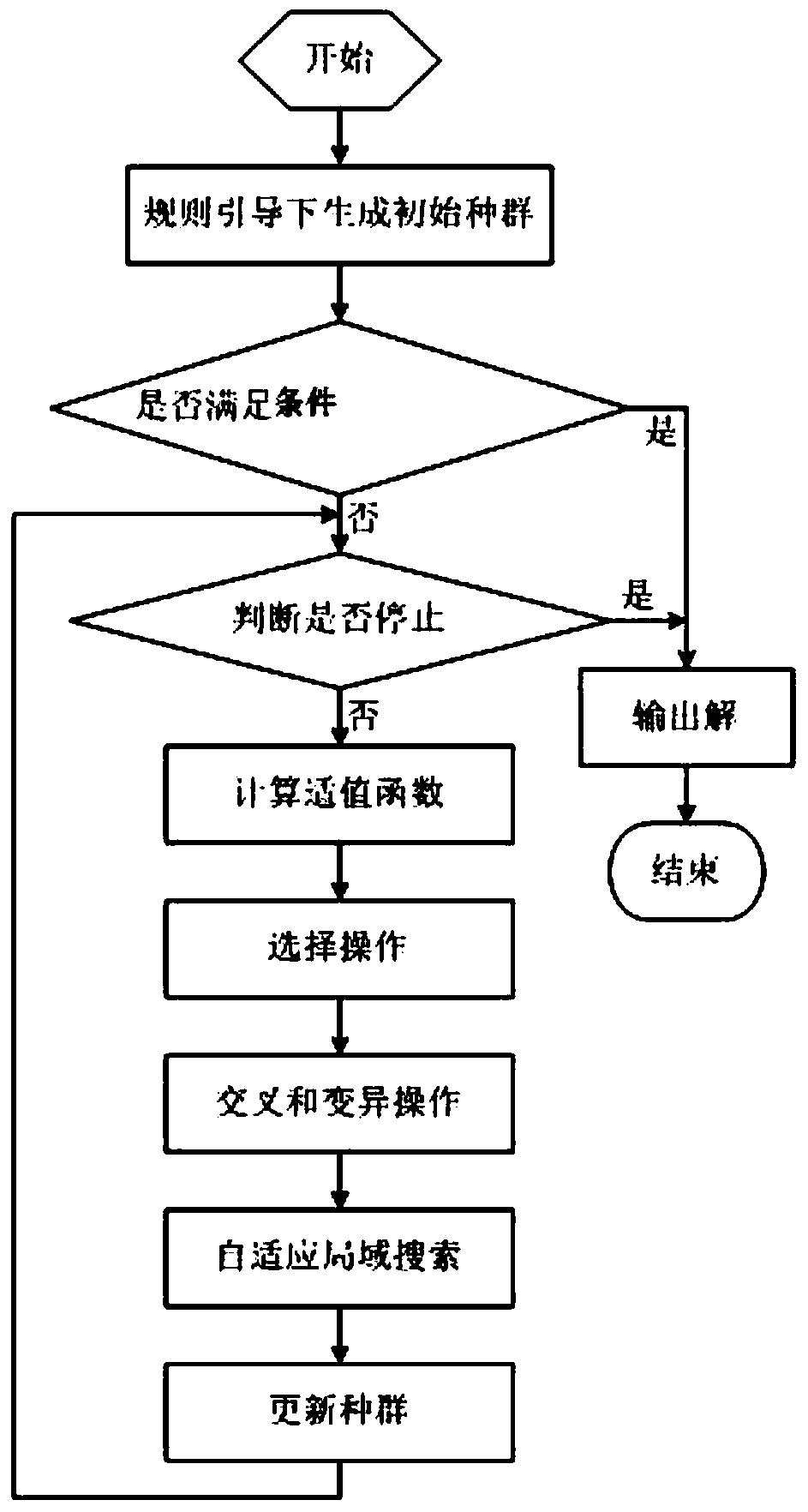

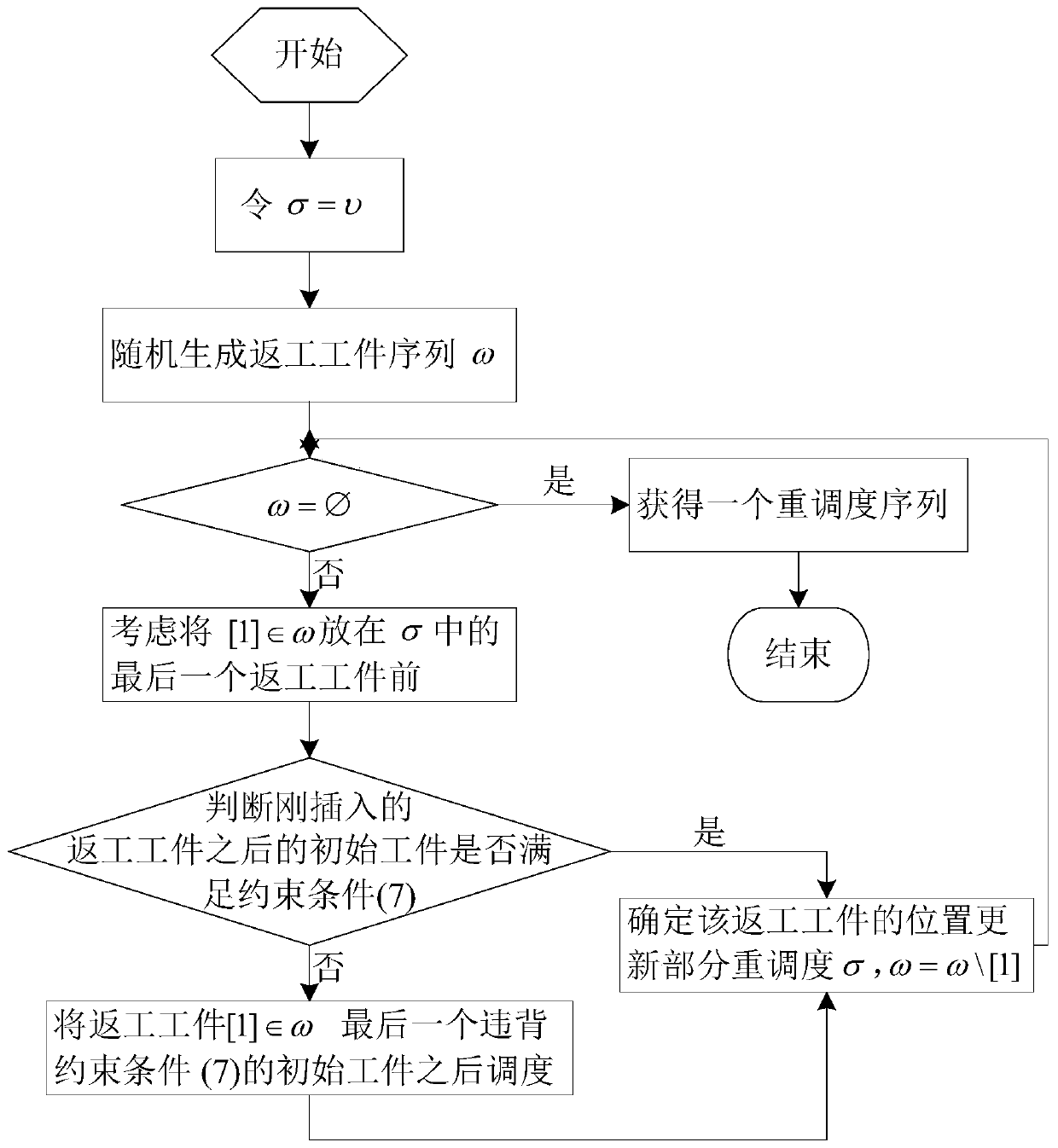

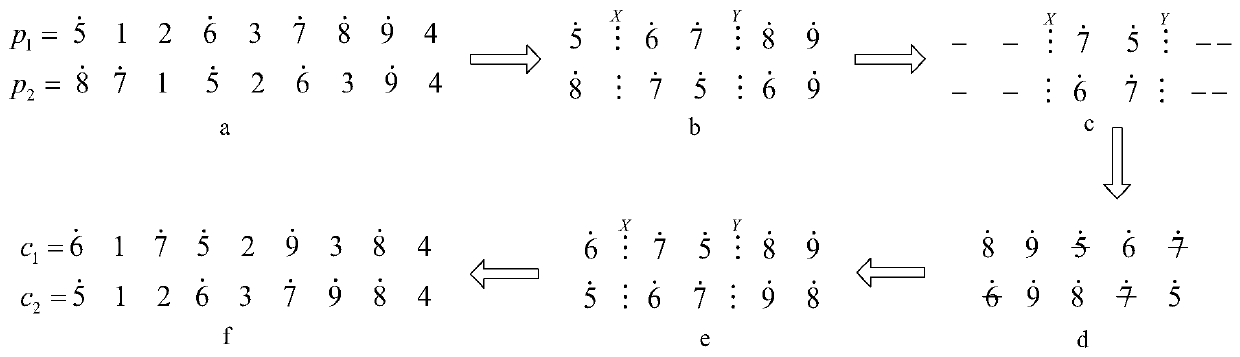

Method used

Image

Examples

Embodiment Construction

[0072] The embodiment of the new workpiece rescheduling method provided by the present invention is as follows:

[0073] Step 1: Build a Mathematical Model

[0074] In a heat treatment station with a known initial workpiece set The initial schedule υ for a set of newly arrived jobs J N ={n O +1,...,n O +n N}, under the premise of meeting the actual process requirements, reschedule all the workpieces, so as to obtain the rescheduling scheme with the goal of minimizing the waiting time of all workpieces;

[0075] The mathematical model is described as follows:

[0076]

[0077] s.t.

[0078] w j (σ)≤K,j∈J O (2)

[0079] the s j (σ)≥r j ,j∈J (3)

[0080]

[0081] ros(σ)=ros(υ) (5)

[0082] Equation (1) is the objective function, that is, to minimize the sum of waiting times of all workpieces, w i Indicates the waiting time for workpiece i to be processed; in formula (2), the initial workpiece’s waiting time in rescheduling σ cannot exceed K; formula (3) ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com