Aircraft electromechanical system sealing structure long-life design method based on particle swarm optimization algorithm

A technology of particle swarm optimization and electromechanical systems, applied in computing, electrical digital data processing, instruments, etc., can solve problems such as aircraft crashes and fatalities, impact on flight life, loss, etc., achieve fast convergence speed, good global search ability, and reduce Calculate the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

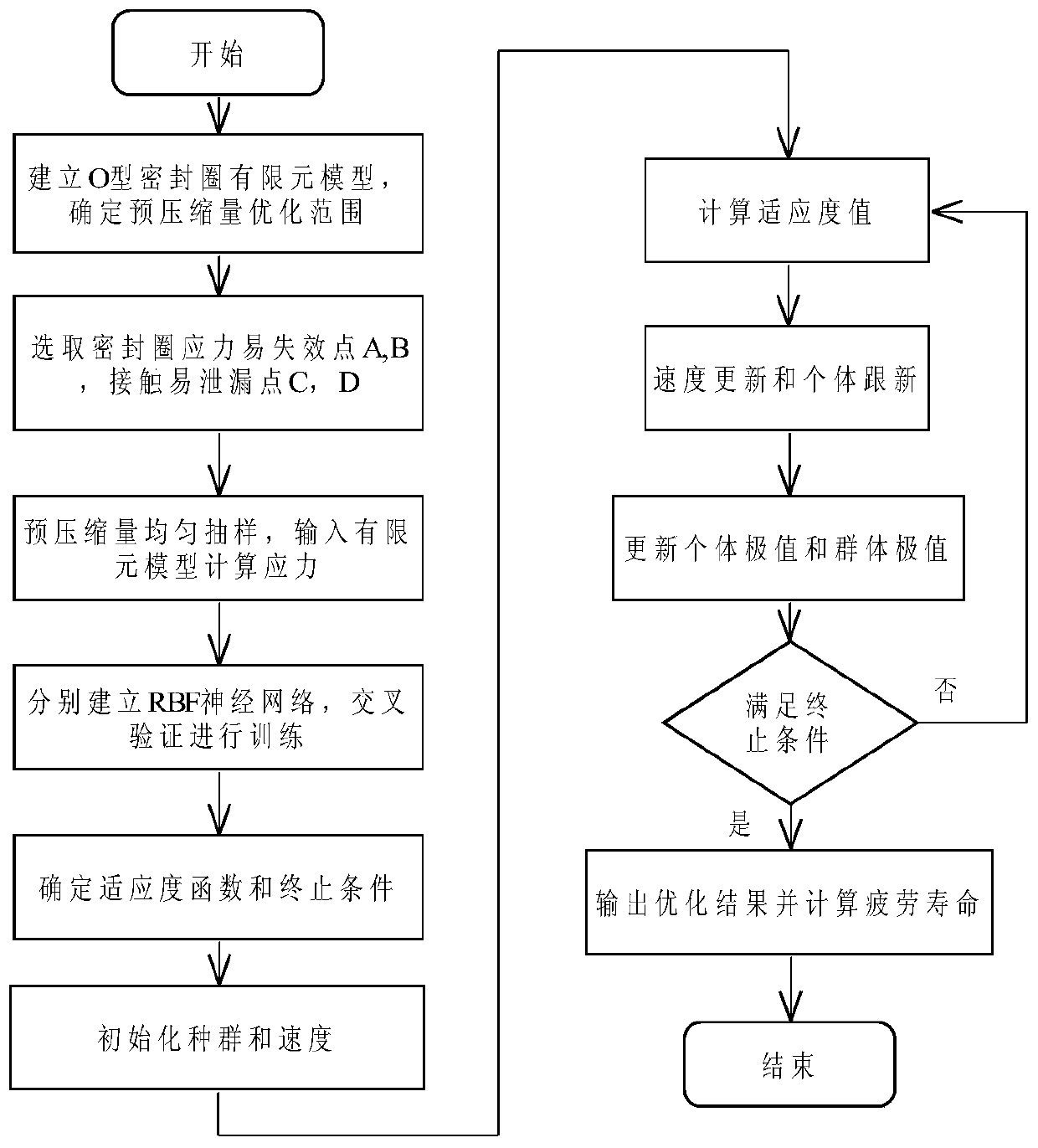

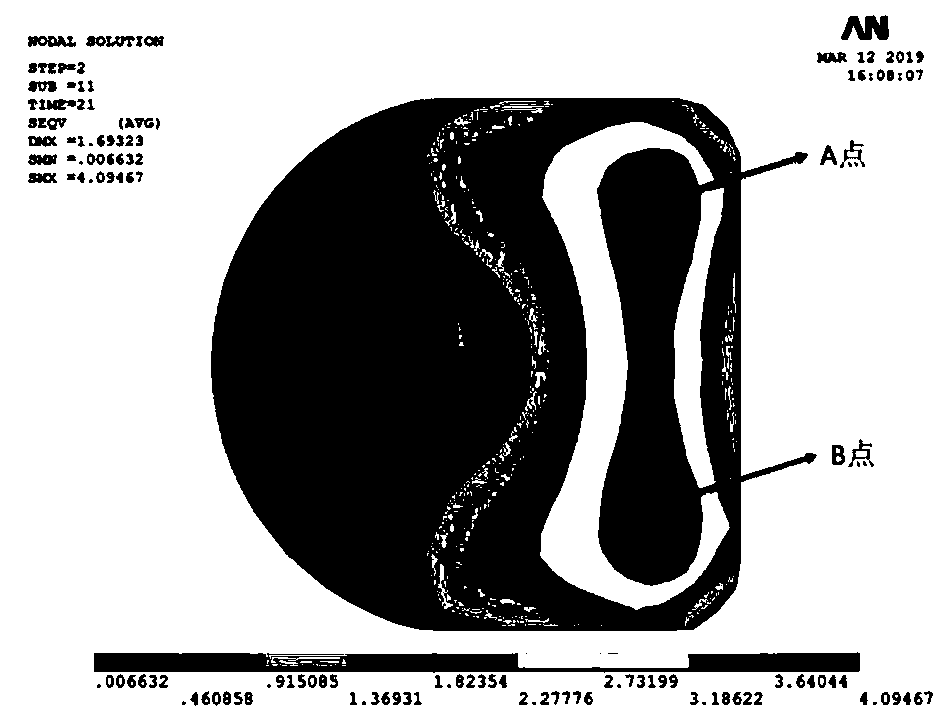

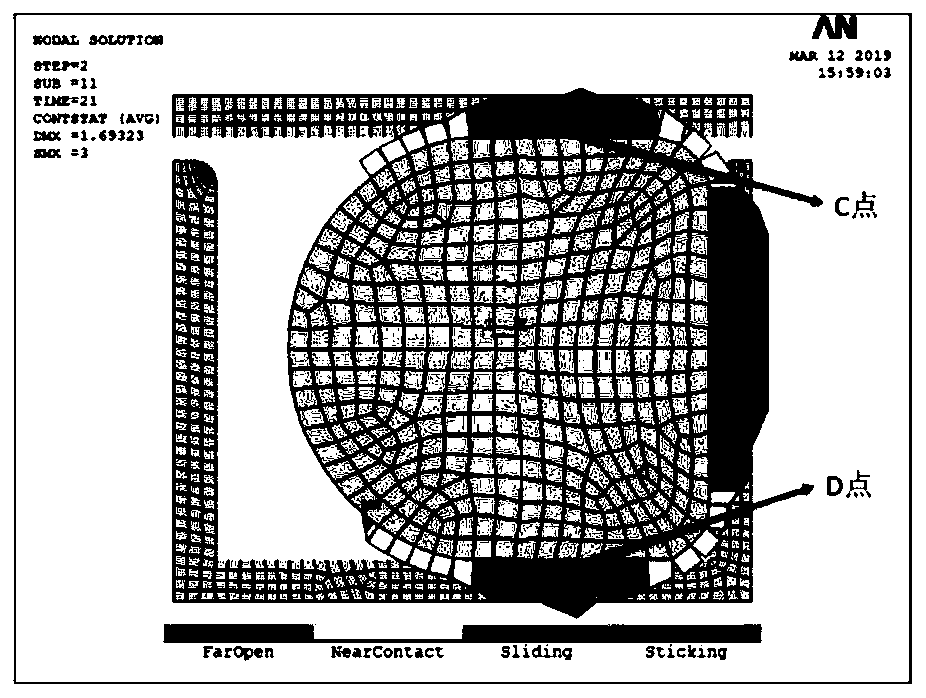

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0027] The present invention attempts to solve the optimization problem under multiple failure modes of the complex sealing structure: under the condition of ensuring that the electromechanical system of the aircraft does not leak, optimize the prestress applied to the sealing ring in order to improve the fatigue life of the sealing ring.

[0028] It can be expressed as

[0029]

[0030] In the formula, S is the life of the sealing ring, σ is the maximum stress of the sealing ring, P oil is the oil pressure of the electromechanical system, F is the prestress, F min and F max are the minimum and maximum prestress values, respectively.

[0031] 1) RBF neural network optimized by cross-validation

[0032] The present invention first aims at the pre-compression amount that needs to be optimized, adopts the method of normal sampling, selects 200 groups of pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com