Electrostatic dissipation type oil mist separation cylinder

A technology of oil mist separation and static electricity dissipation, applied in the direction of dispersed particle separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor aerosol separation effect and low particle capture efficiency, so as to reduce the possibility and improve the aerosol Separation effect, effect of increasing collision probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The invention adopts the principle of static electricity dissipation to improve the effect of oil mist separation, and distributes multiple detailed designs, further improves the effect of oil mist separation under the condition of very low operating cost, and solves the problem that the effect of oil mist separation in the prior art is difficult to improve .

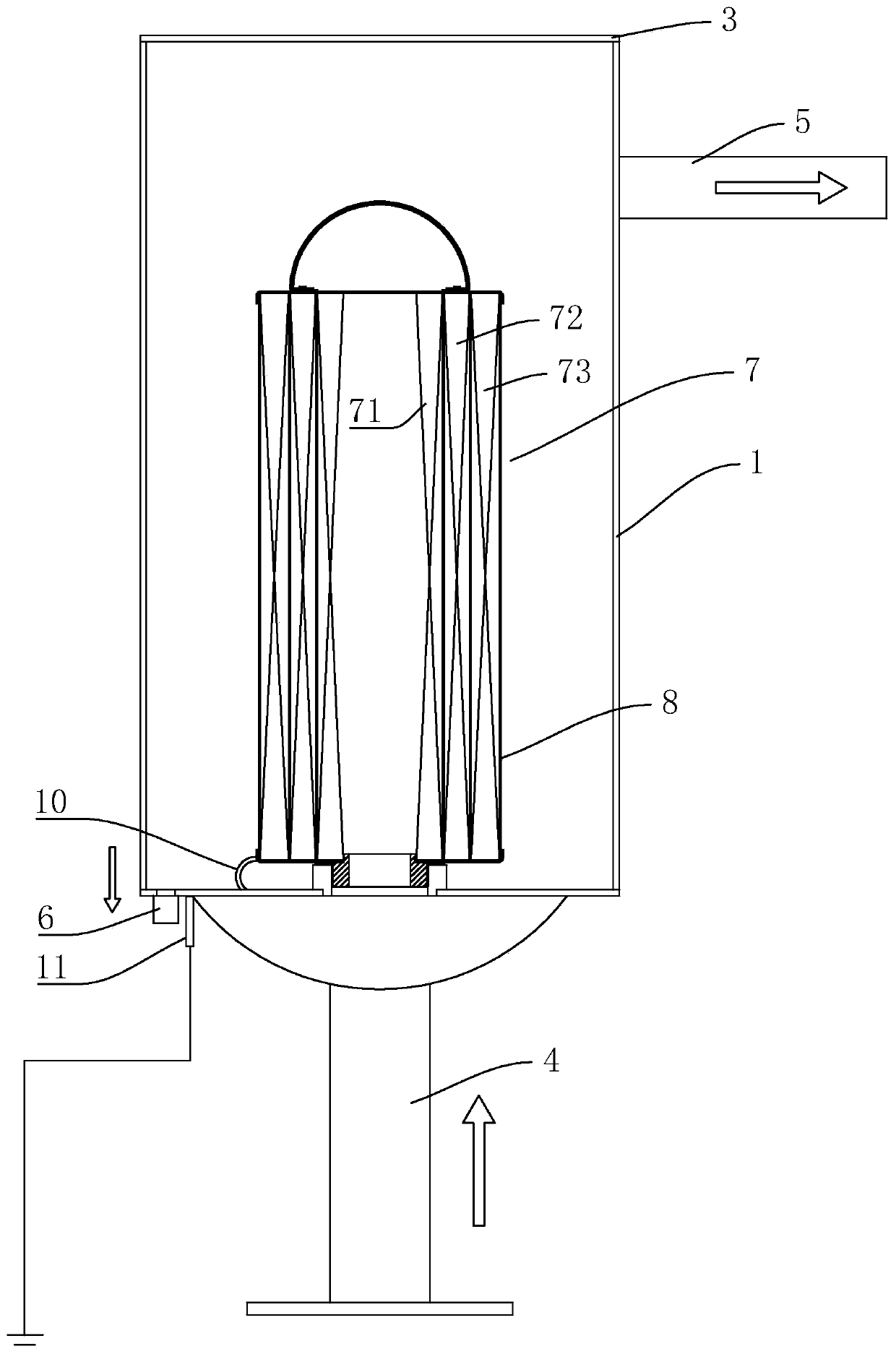

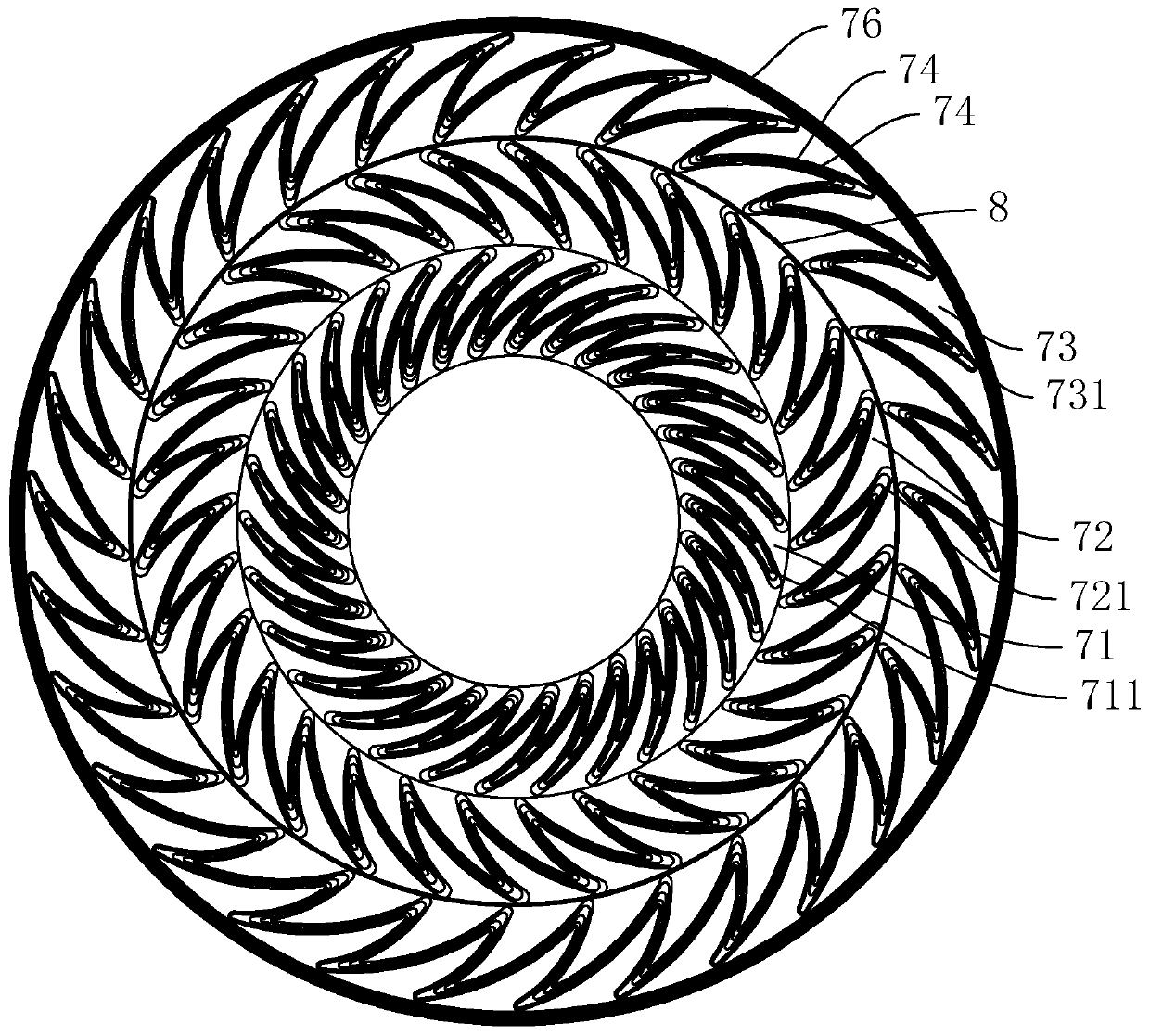

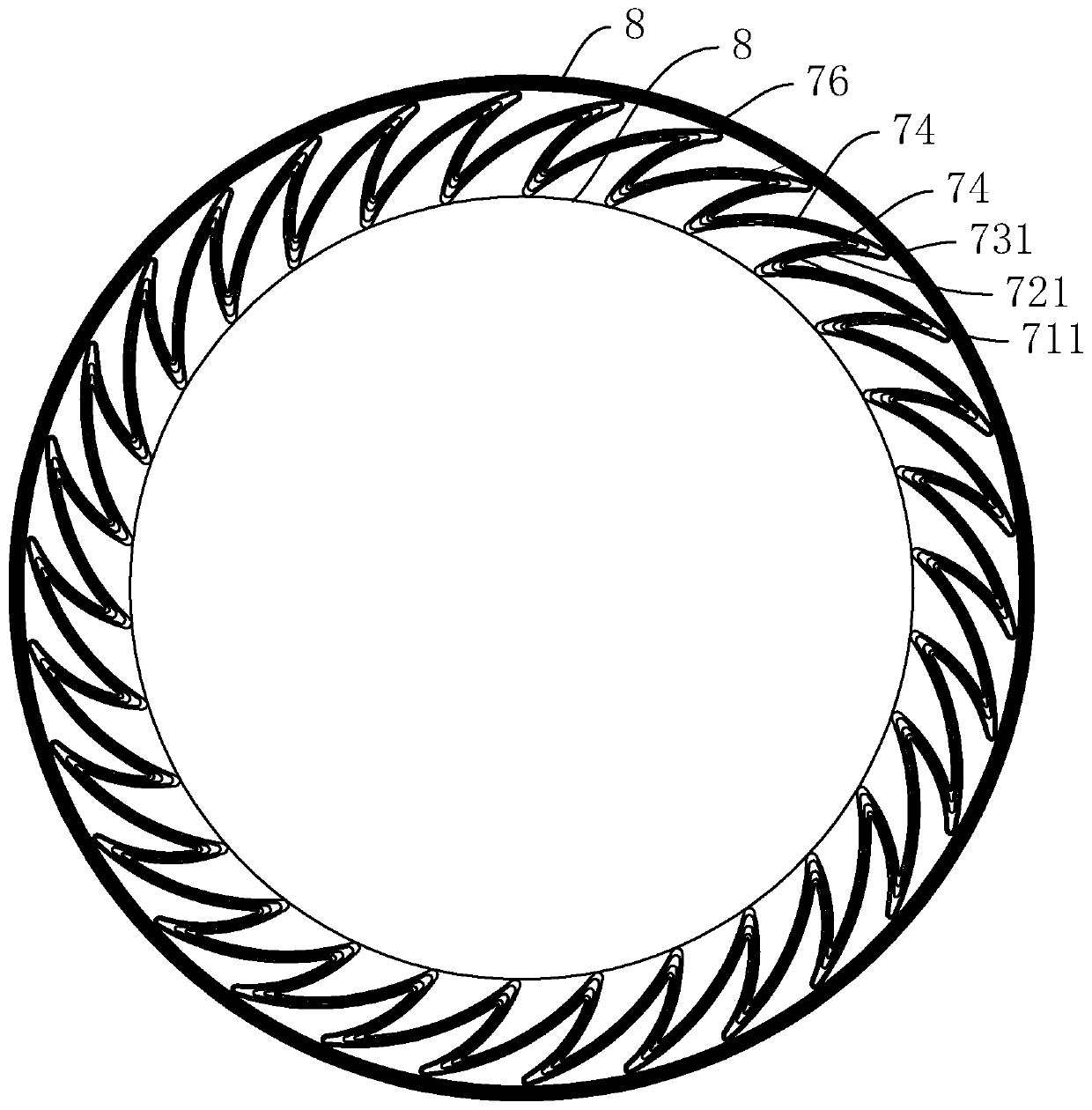

[0037] Such as figure 1 As shown, a static dissipative oil mist separation cylinder includes an outer shell 1 and a separation cylinder 7. The outer shell 1 is connected with a cover plate 3, the lower end of the outer shell 1 is provided with an air inlet 4 for the inflow of oil and gas mixed gas, the side wall of the outer shell 1 is provided with an air outlet 5, and the separation cylinder 7 is provided with an oil outlet 6. A separation cylinder 7 for oil and gas separation is installed in the outer housing 1. The separation cylinder 7 is installed on the bottom plate of the outer housing 1. There is a channel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com