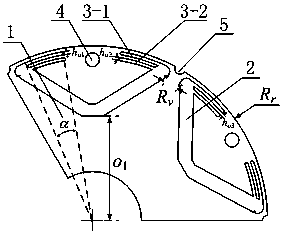

Rotor structure of a built-in permanent magnet synchronous motor

A permanent magnet synchronous motor and rotor structure technology, applied in synchronous machine parts, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc. times, achieve mutual cancellation, and improve power and torque density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

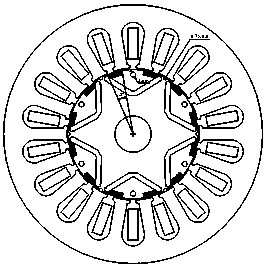

[0024] Such as figure 2 As shown, this embodiment has a structure of 6 poles and 18 slots, adopts a distributed winding structure, and the angle of the center of the rotor occupied by the arc-shaped slots on the outer layer is 14°. The diameter of the circular hole 4 is 2mm, and the radius of the semicircular groove on the outer edge of the rotor core is 0.75mm.

Embodiment 2

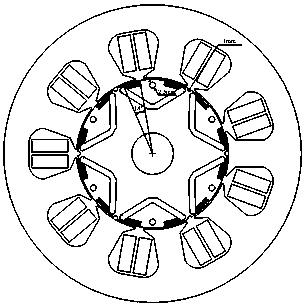

[0026] Such as image 3 As shown, this embodiment has a structure of 6 poles and 9 slots, adopts a centralized winding structure, and the angle of the center of the rotor occupied by the arc-shaped slots on the outer layer is 18°. The diameter of the circular hole 4 is 2.5mm, and the radius of the semicircular groove on the outer edge of the rotor core is 1mm.

Embodiment 3

[0028] Such as Figure 4 As shown, this embodiment has a structure of 8 poles and 12 slots, adopts a centralized winding structure, and the angle of the center of the rotor occupied by the outer arc-shaped slots is 10°. The diameter of the circular hole 4 is 2mm, and the radius of the semicircular groove on the outer edge of the rotor core is 1.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com