Tail door pushing rod outer pipe fixing structure

A technology of fixing structure and outer tube, applied in door/window fittings, building structure, power control mechanism, etc., can solve the problems of complicated push rod assembly, easy connection failure, large workload, etc., to achieve simple and convenient assembly, prevent The effect of good rotation and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

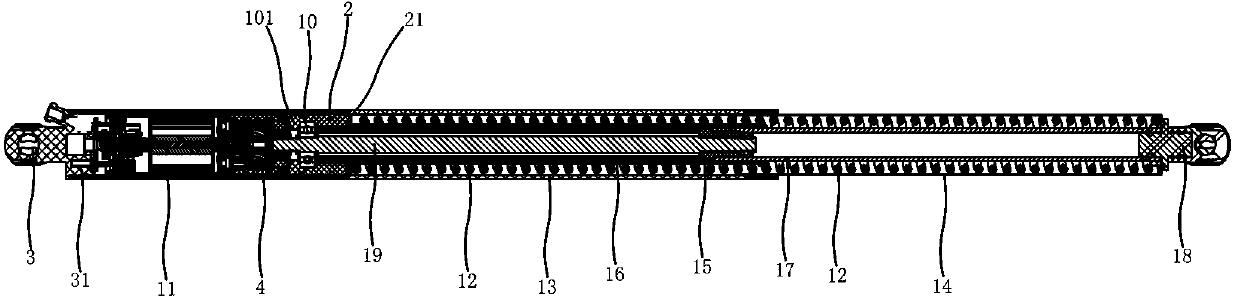

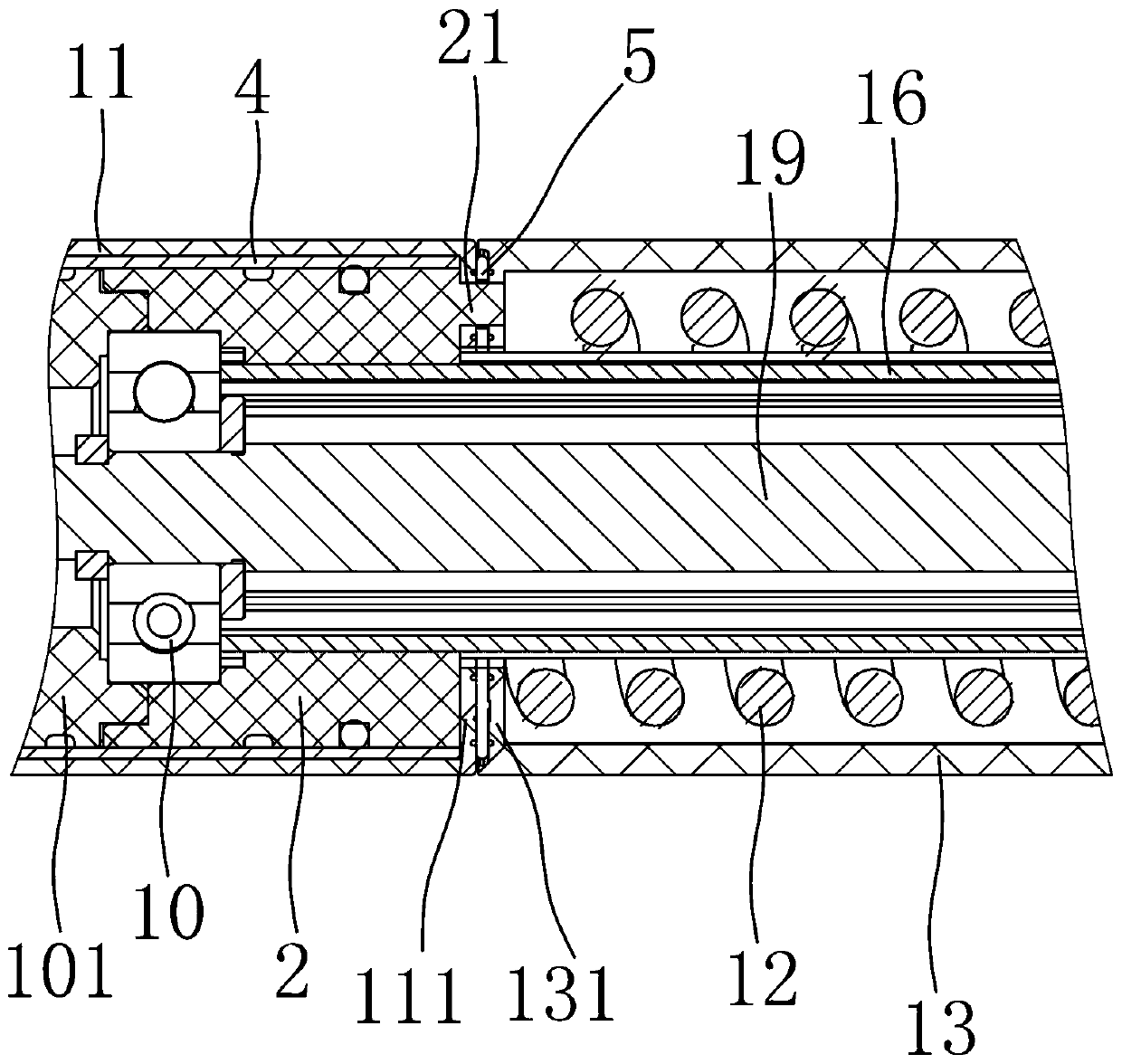

[0040] Depend on Figure 1 to Figure 6 As shown, a tailgate push rod outer tube fixing structure of the present invention includes a motor outer tube 1 for accommodating the driving part, a spring outer tube 13 for protecting the compression spring 12 and a top tube outer tube 14, The conduit 16 used to guide the screw nut 15, the top tube 17 fixed to the screw nut 15, the end of the top tube 17 away from the screw nut 15 is fixed with a first ball head assembly 18, and one end of the screw rod 19 passes through the bearing 10 is fixed in the motor outer tube 11, the jacking tube outer tube 14 is sleeved outside the jacking tube 17 and fixed with the first ball head assembly 18, the spring outer tube 13 and the jacking tube outer tube 14 are mutually sleeved, and the spring outer tube 13 There is a seal between the jacking pipe outer tube 14, and the end of the motor outer tube 11 close to the spring outer tube 13 is provided with a guide sleeve 2, and the end of the guide tub...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that, except for the seal, other structures of this embodiment are the same as those in Embodiment 1.

[0049] Depend on Figure 11 to Figure 14 As shown, in the spring outer tube 13 and the jacking tube outer tube 14 that are nested with each other, the spring outer tube 13 is a plastic tube, the jacking tube outer tube 14 is a metal tube, and a seal is provided between the spring outer tube 13 and the jacking tube outer tube 14. 70 pieces. The seal includes a fixed sleeve 71 and a rubber sleeve 72 fixed on the fixed sleeve 71. The rubber sleeve 72 is glued and fixed on the circumferential inner side of the fixed sleeve 71, and the rubber sleeve 72 is formed on the circumferential surface of the side away from the fixed sleeve 71. The sealing protruding ring 73, several sealing protruding rings 73 are arranged at intervals along the axial direction, the spring outer tube 13 is fixed with the fixing sleeve 71 o...

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is that, except for the seal, other structures of this embodiment are the same as those in Embodiment 1; the difference between this embodiment and Embodiment 1 lies in the difference between the seal and the spring outer tube.

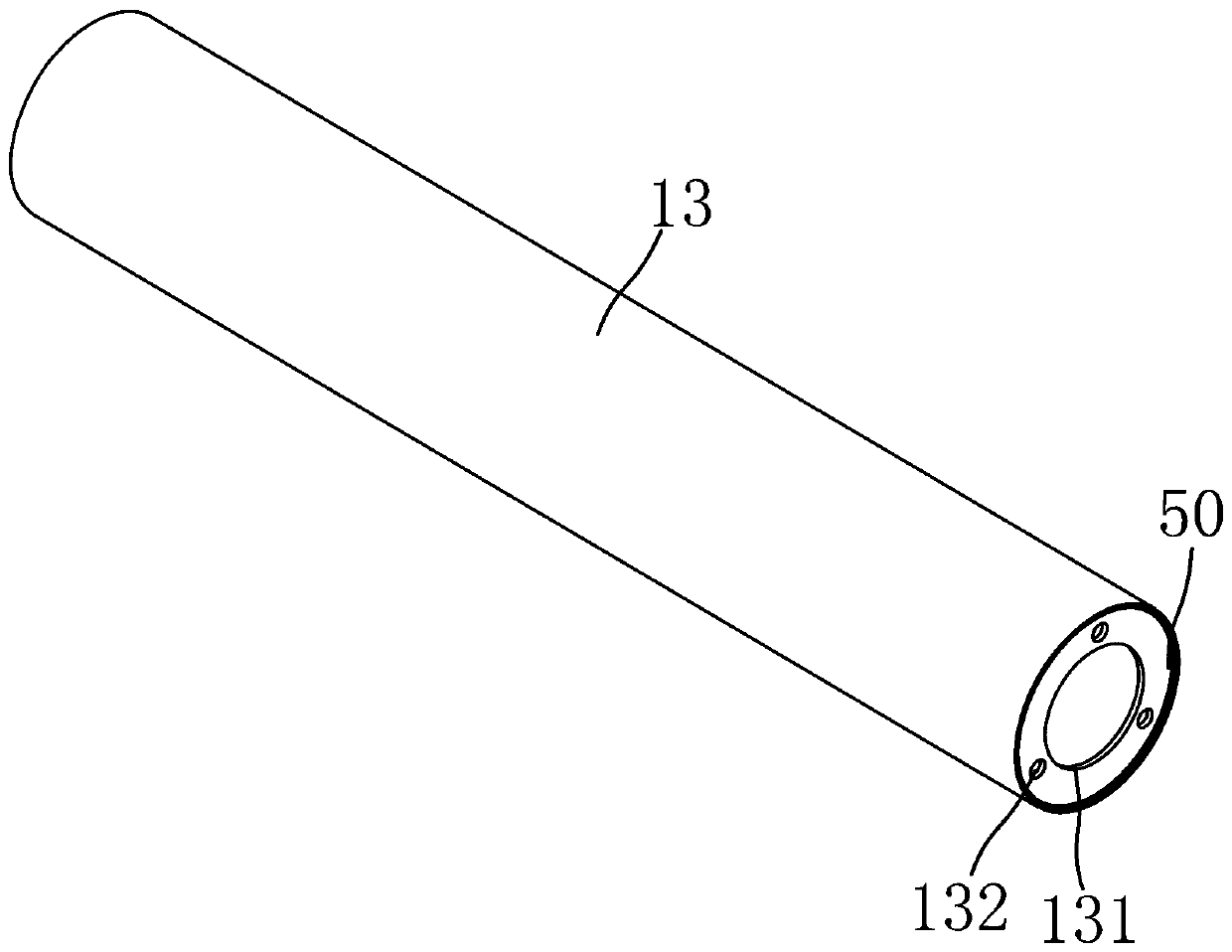

[0055] Depend on Figure 15 to Figure 19 As shown, in the spring outer tube 13 and the jacking tube outer tube 14 that are nested with each other, the spring outer tube 13 is a plastic tube, and the jacking tube outer tube 14 is a metal tube. The seal 80 is fixed to the spring outer tube 13 . A plurality of annular grooves 131 are formed on the inner wall of the spring outer tube 13. The plurality of annular grooves 131 are arranged at intervals along the axis of the spring outer tube 13. The sealing member 80 includes a metal part 81 and a colloid 82 coated on the metal part 81. The colloid 82 is annular , the circumferential outer edge part of the colloid 82 wraps the metal part 81 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com