Piston-type hydraulic chuck, power head and drilling rig

A hydraulic chuck and piston type technology, which is applied in the direction of drill pipe, drill pipe, earth cube drilling, etc., can solve the problems of easy accumulation of rock dust, slow response of chuck opening, etc., and achieves easy maintenance, simple structure, and reliability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1. Piston hydraulic chuck:

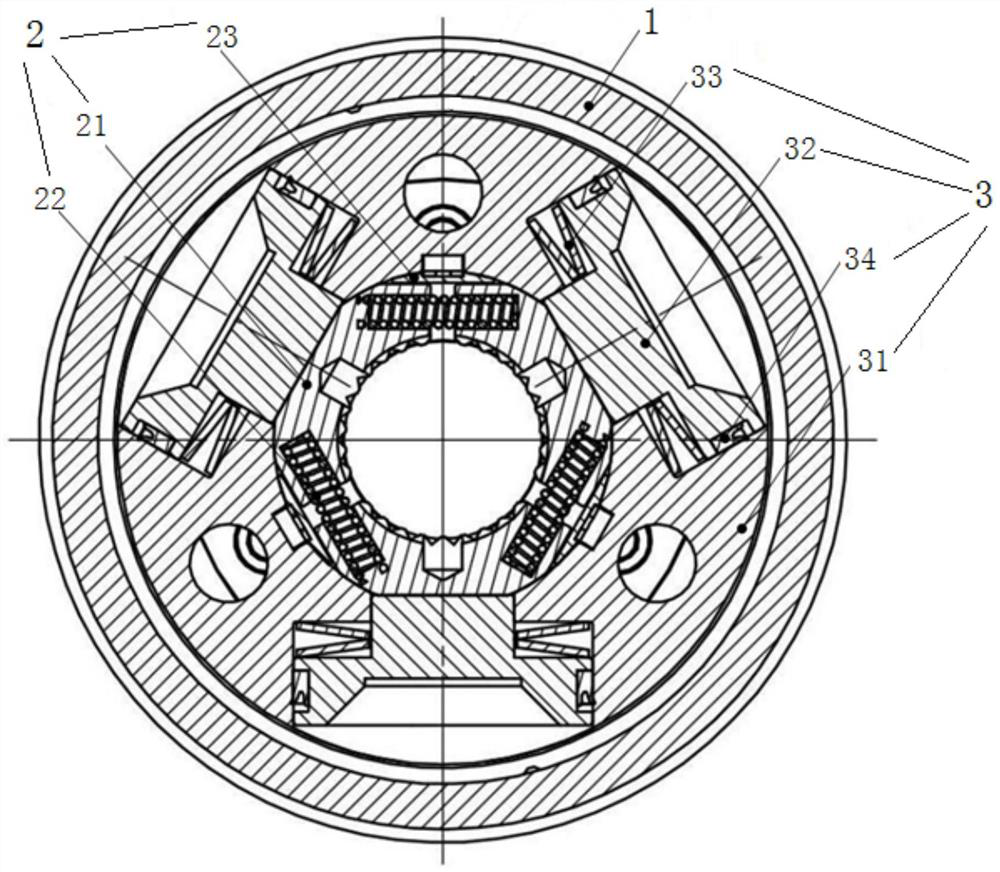

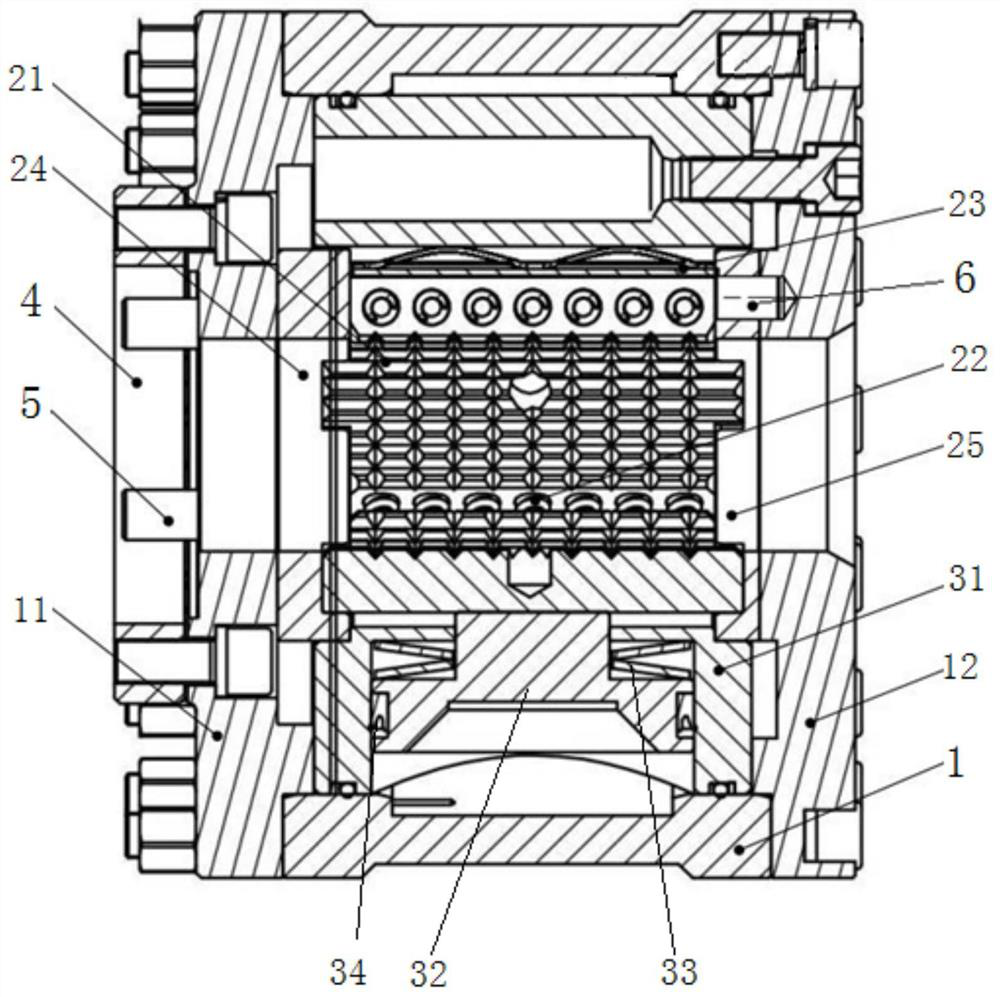

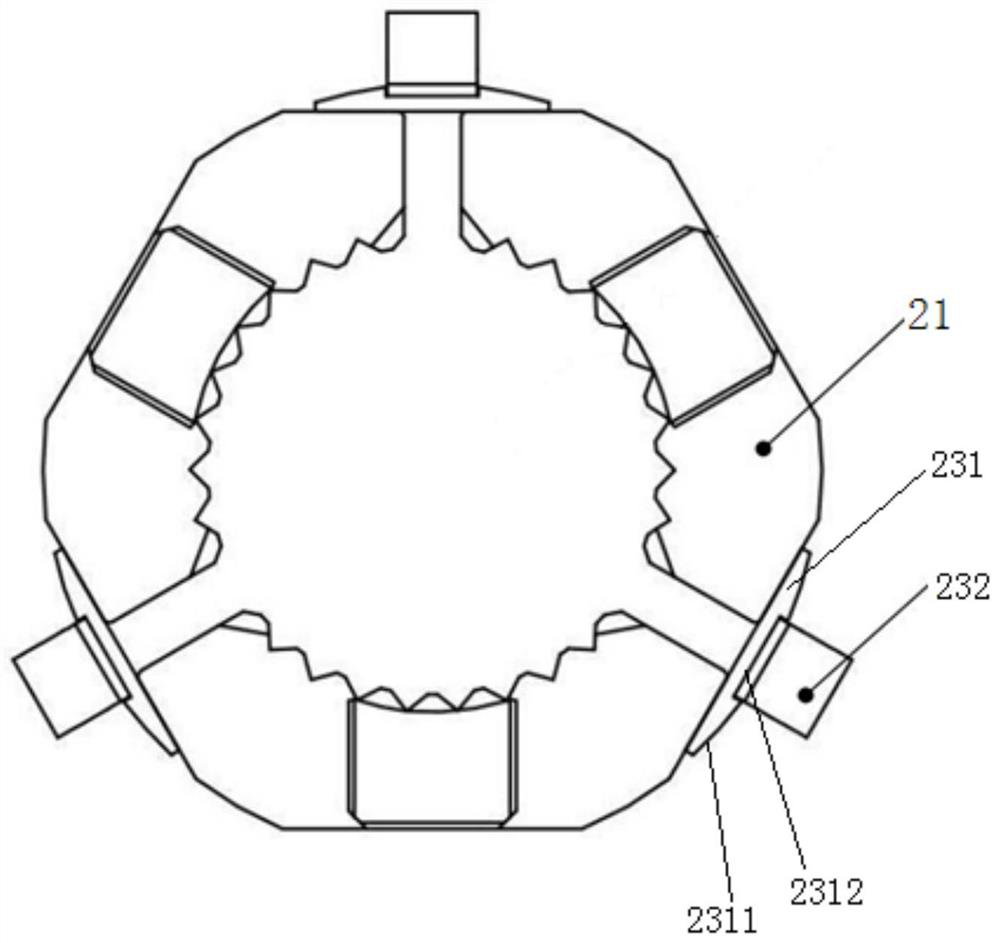

[0046] combine Figure 1-4 , the piston hydraulic chuck of this embodiment includes a chuck body 1, and a slip assembly 2 and a radial power assembly 3 are arranged radially in the chuck body 1, and the slip assembly 2 includes a plurality of chucks arranged circumferentially. The shoe 21 is connected by a return spring 22 between adjacent slips 21; an elastic barrier 23 is arranged corresponding to the gap between adjacent slips 21, and one end of the elastic barrier 23 is pressed against the radial power assembly 3, and the other end of the elastic barrier 23 The gap between adjacent slips 21 is blocked.

[0047] The slip assembly 2 is provided with three groups of slips 21 along the circumferential direction for clamping the drill pipe; a return spring 22 is provided between adjacent slips 21; the radial power assembly 3 includes a radial oil cylinder 31 and a radial piston 32 And the disc spring 33, the outer middle planes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com