Display substrate and manufacturing method thereof, display panel and display device

A display substrate and manufacturing method technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems affecting the performance of OLED display substrates, and the inorganic film layer is prone to cracks, etc., to achieve the effect of improving long-term reliability and ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

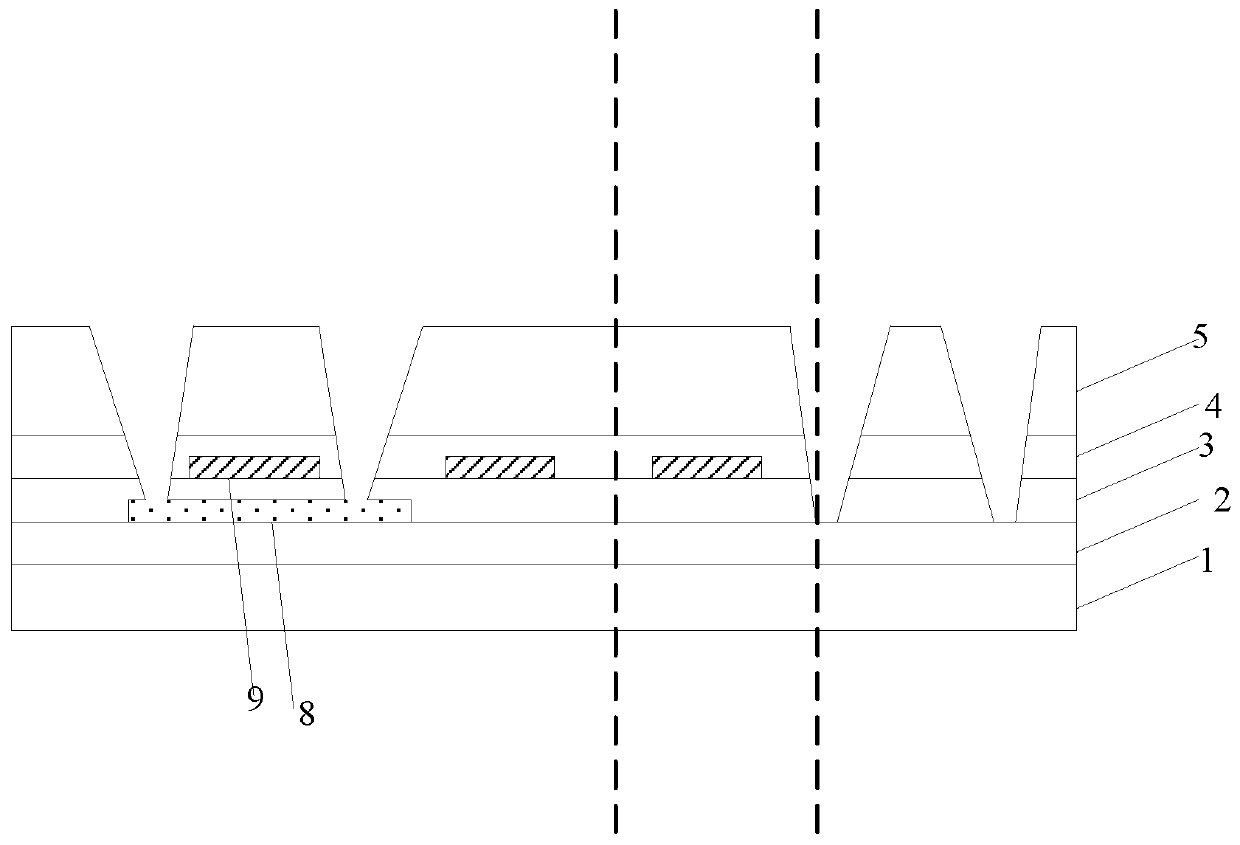

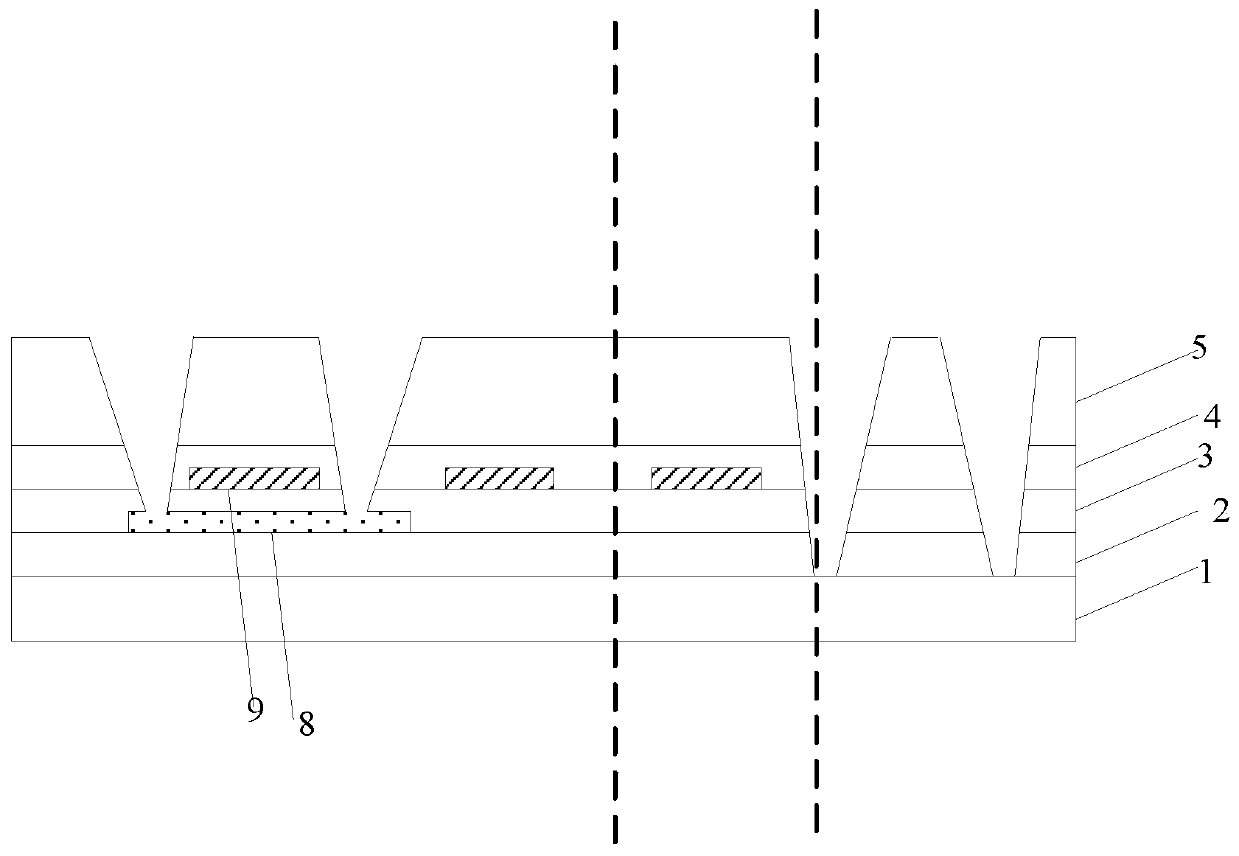

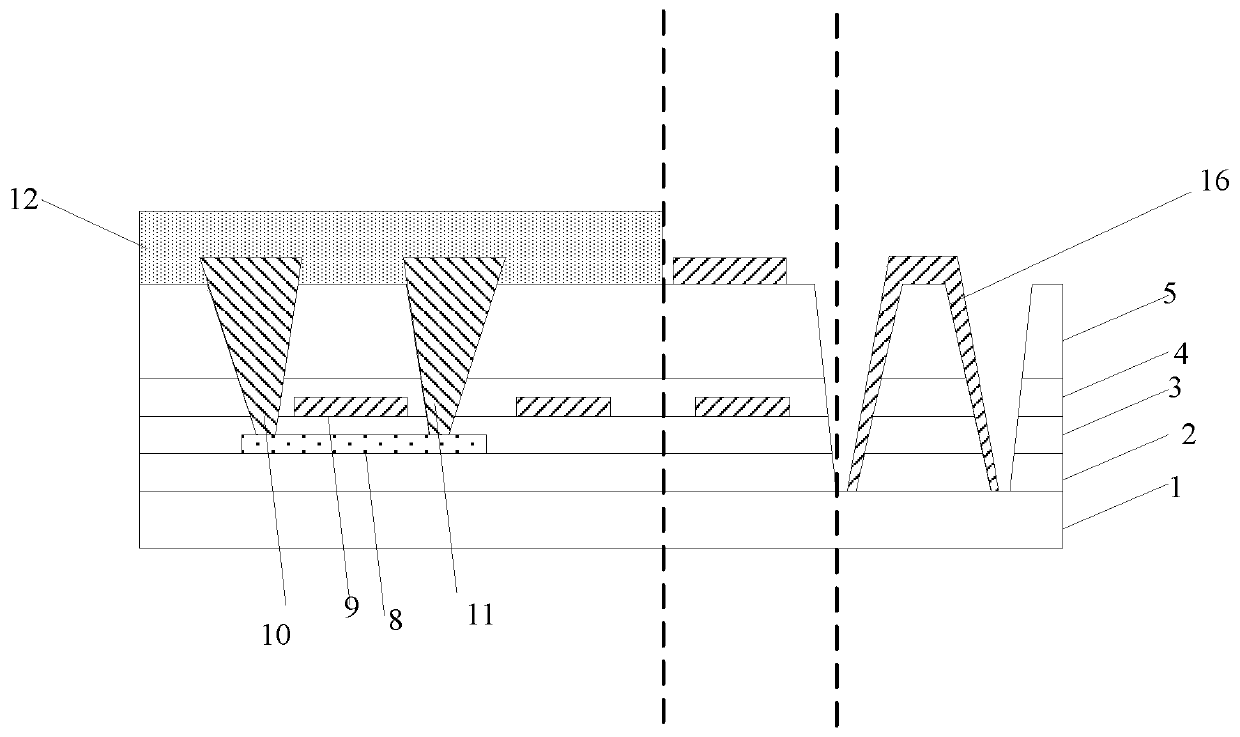

[0060] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0061] Embodiments of the present invention provide a display substrate and its manufacturing method, a display panel, and a display device, which can prevent cracks or cracks in the buffer inorganic film layer from being transmitted to the wiring area and even the inorganic film layer in the display area, and ensure the performance of the display substrate. , Improve the long-term reliability of the display substrate.

[0062] An embodiment of the present invention provides a display substrate motherboard, including a functional area and a buffer zone between the functional area and the boundary of the display substrate, the functional area includes a display area provided with an OLED display device and a buffer zone located between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com