Apparatus and method for preparing cable joints

A technology for cable joints and preparation devices, which is applied in the field of power tools, can solve problems such as cable insulation strength reduction, cable joint breakdown damage, and influence on line power supply, and achieve the effects of small connection resistance, high connection stability, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

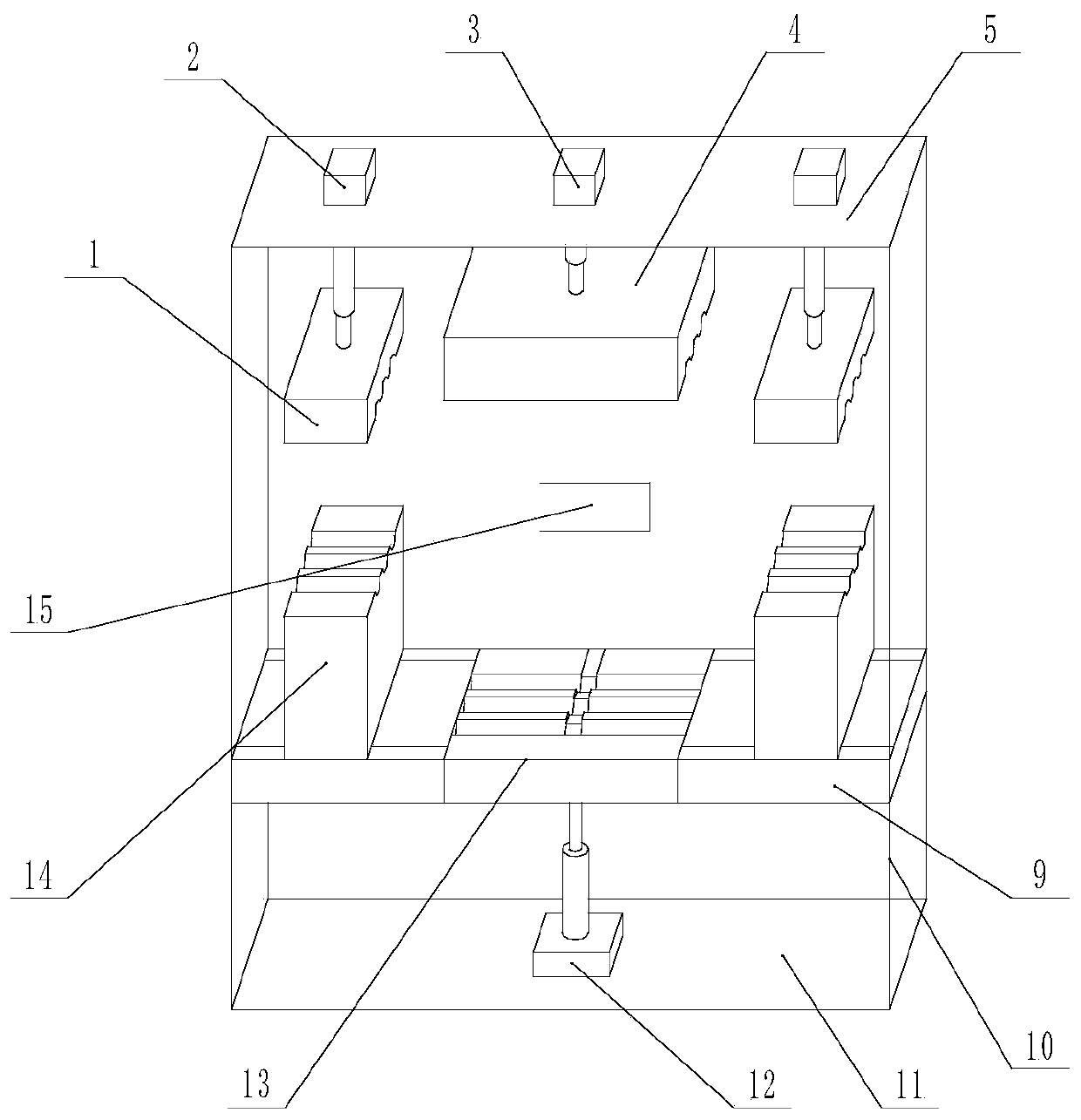

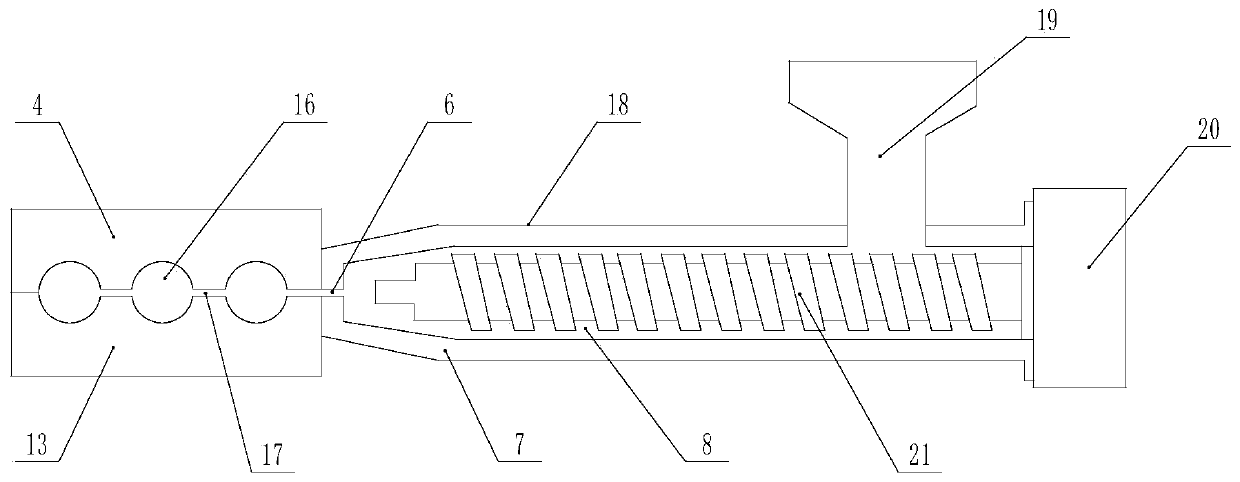

[0024] The preparation device for the cable joint includes a support device and a docking device, the support device includes a support plate 5 and a base 11 connected by a bracket 10, the docking device includes a press-fit head 1 and a press-fit disc 14, press-fit The head 1 is connected to the press-fit motor 2 through a telescopic rod, the press-fit motor 2 is fixed on the support plate 5, the press-fit disc 14 is fixed on the support platform 9, and the support platform 9 is fixed on the bracket 10. The preparation device for the cable joint Injection molding device is also included. The injection molding device is composed of injection molding head 4, injection molding disc 13 and injection molding mechanism 15. The injection molding pressing head 4 is driven by the motor I3 fixed on the support plate 5, and the injection molding disc 13 is driven by the motor II 12 fixed on the base 11. drive.

Embodiment 2

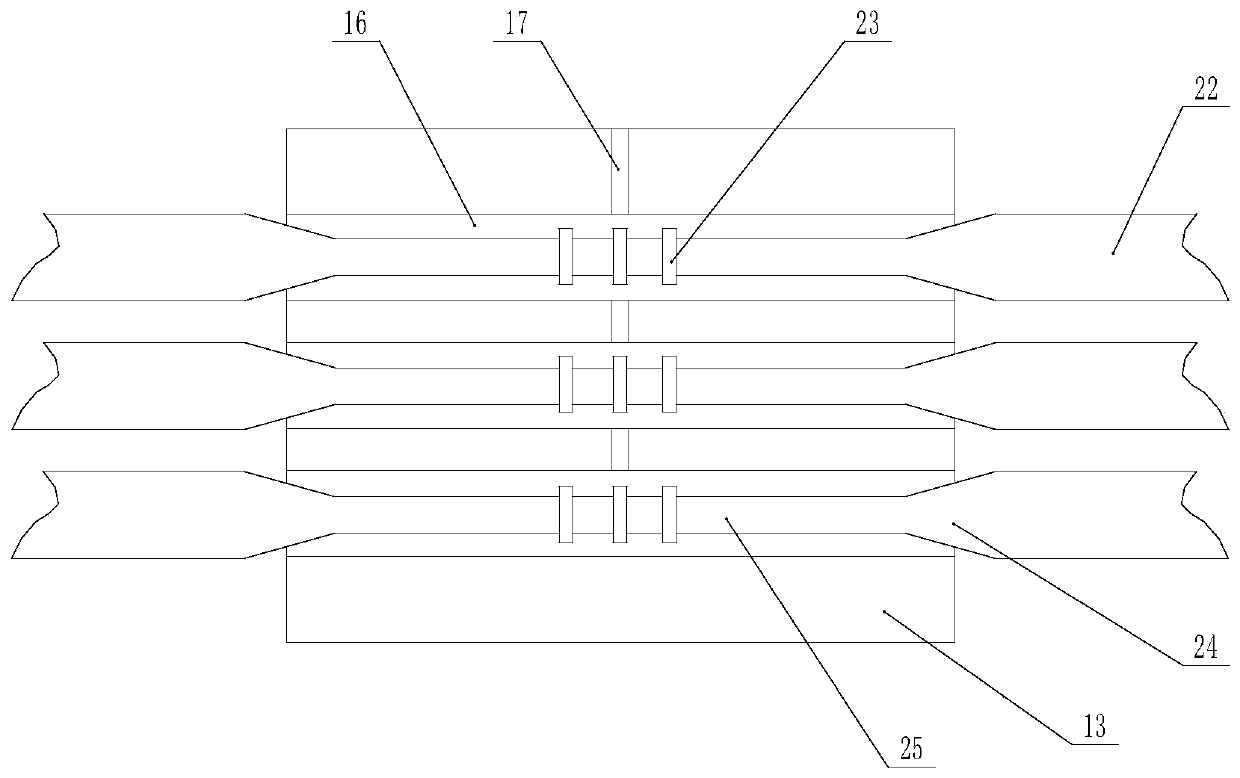

[0026] The preparation device for the cable joint includes a support device and a docking device, the support device includes a support plate 5 and a base 11 connected by a bracket 10, the docking device includes a press-fit head 1 and a press-fit disc 14, press-fit The head 1 is connected to the press-fit motor 2 through a telescopic rod, the press-fit motor 2 is fixed on the support plate 5, the press-fit disc 14 is fixed on the support platform 9, and the support platform 9 is fixed on the bracket 10. The preparation device for the cable joint Injection molding device is also included. The injection molding device is composed of injection molding head 4, injection molding disc 13 and injection molding mechanism 15. The injection molding pressing head 4 is driven by the motor I3 fixed on the support plate 5, and the injection molding disc 13 is driven by the motor II 12 fixed on the base 11. Drive; the injection molding tray 13 and the press-fit tray 14 are provided with a ca...

Embodiment 3

[0029] The preparation device for the cable joint includes a support device and two sets of docking devices, the support device includes a support plate 5 and a base 11 connected by a bracket 10, the docking device includes a press-fit head 1 and a press-fit disc 14, The press-fit head 1 is connected with the press-fit motor 2 through a telescopic rod, the press-fit motor 2 is fixed on the support plate 5, the press-fit disc 14 is fixed on the support platform 9, and the support platform 9 is fixed on the support 10. The preparation device also includes an injection molding device. The injection molding device is composed of an injection molding head 4, an injection molding disc 13 and an injection mechanism 15. The injection molding pressing head 4 is driven by a motor I3 fixed on the support plate 5, and the injection molding disc 13 is driven by a motor I3 fixed on the base 11. Driven by motor II12; the injection molding tray 13 and the press-fit tray 14 are provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com