Instant pre-fixation of adhesive bonded insert parts which is preferably made of plastic with the help of chemical screws

An adhesive and thermal curing technology, applied in the direction of adhesives, material bonding, adhesive types, etc., can solve the problems of low commercial effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

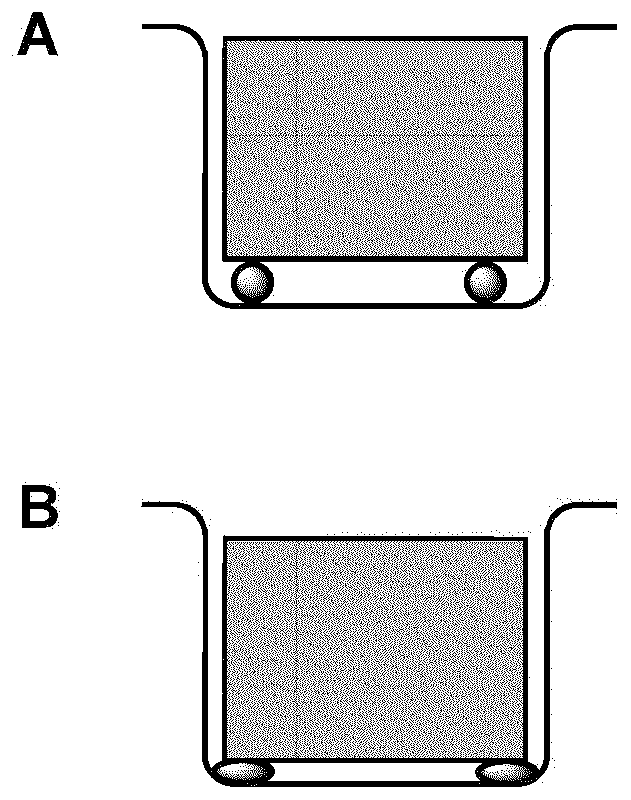

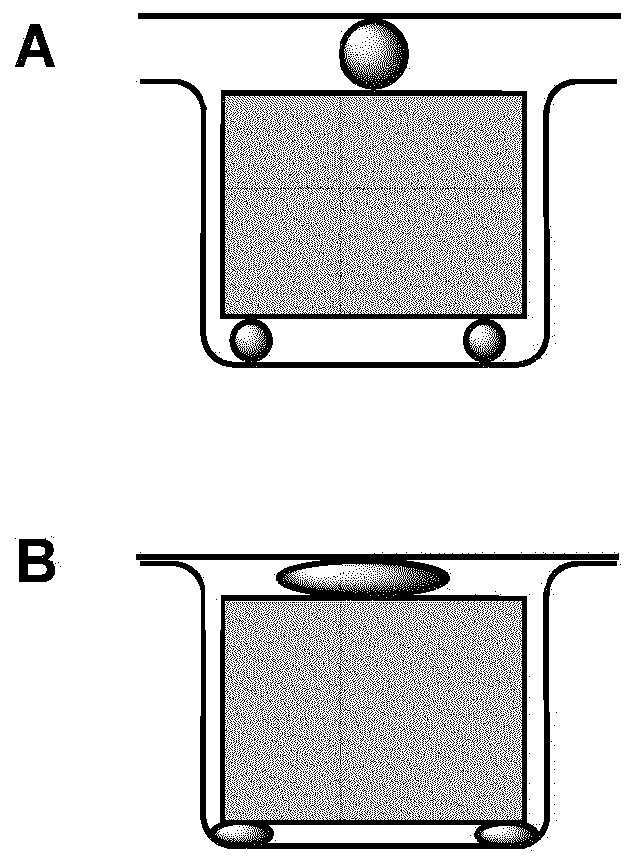

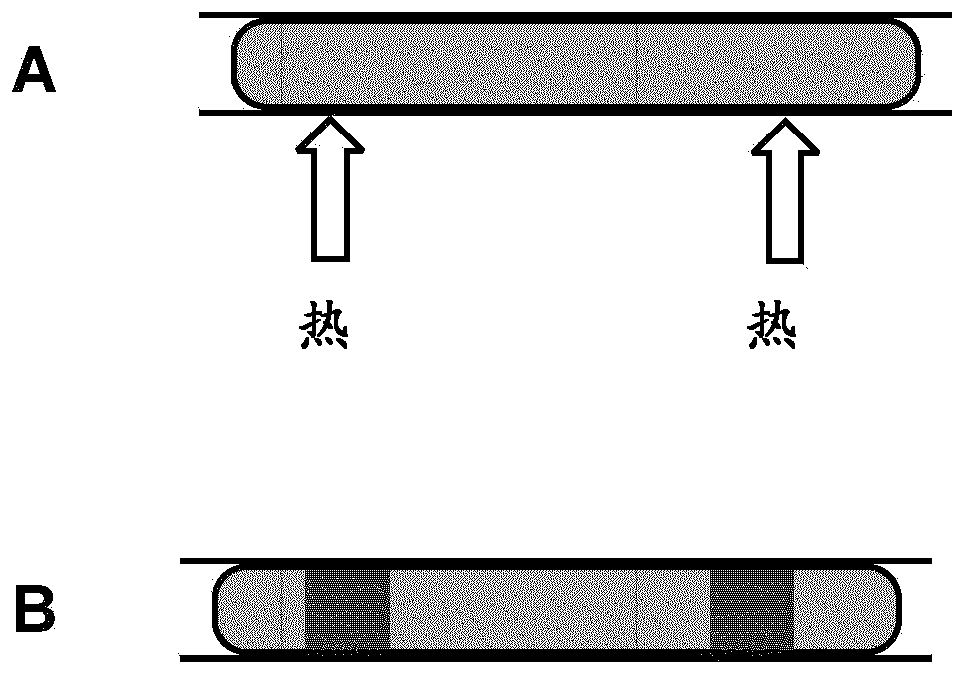

Image

Examples

Embodiment 1

[0137] To test the inventive concept, different adhesives were pre-cured on aluminum with different parameters by induction. The resulting products were compared for tensile shear strength and reactivity. In addition, it was investigated whether pre-curing and subsequent full curing had an effect on the stability of adhesive bonded joints.

[0138] Use the following materials as adhesives:

[0139] a) SikaPower-490B3, Ch: 0011082913 / 1445 (Sika Italy, Cerano)

[0140] b) Betamate 1480 (Dow)

[0141] c) Terokal 8026 (Henkel)

[0142] Additional test parameters are as follows:

[0143] Substrate: AA6016 TiZr

[0144] Cleaning: None, sample as supplied

[0145] Applied: RT

[0146] Size of adhesive film: 25×10×0.3mm

[0147] Lateral movement speed: 10mm / min

[0148] Initial temperature sensing: 50°C

[0149] Pre-curing: induction device EW2

[0150] Specific parameters for the induction test are provided in the table below:

[0151] Table 1:

[0152]

[0153] PWM: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com