Method for operating an internal combustion engine installed in a vehicle

A technology in internal combustion engines and vehicles, which is applied in the direction of internal combustion piston engines, combustion engines, and electronic control of exhaust gas treatment devices. It can solve problems such as unreasonable engine control system design customers, difficulty in compliance with emission limits, and large degrees of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

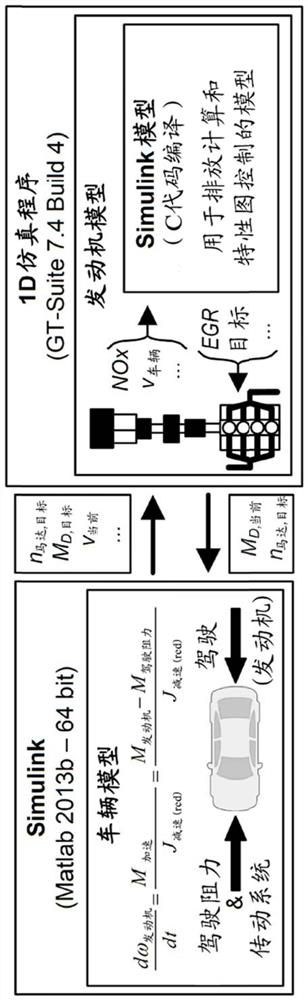

[0047] The basis for the developed model for calculating the engine processes as well as the tests carried out formed a four-cylinder diesel engine with common rail direct injection system and exhaust gas turbocharging. The 2.0-litre in-line engine (Reihenmotor) achieves a maximum full-load torque of 330Nm and delivers up to 110kW at the rated output point. Therefore, as standard, a water / air-charge-air cooler is used to cool the compressed intake air, which operates in a separate low-temperature circuit. NO x The internal engine reduction of emissions takes place via a combined EGR system consisting of low pressure exhaust gas recirculation and high pressure exhaust gas recirculation (LP-EGR and HP-EGR). In the case of LP-EGR, the exhaust gas part flow discharged after the DPF is cooled before being introduced into the compressor line by means of a heat exchanger. Furthermore, the baffles in the exhaust system partially achieve the necessary pressure gradient for this purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com