Atomizing nozzle based on spiral airflow

A technology of atomizing nozzles and spiral airflow, which is applied in the direction of spraying devices and liquid spraying devices, can solve the problems of insufficient water mist humidity effect and gas fluctuation, and achieve the effect of uniform water mist particles and insufficient solution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

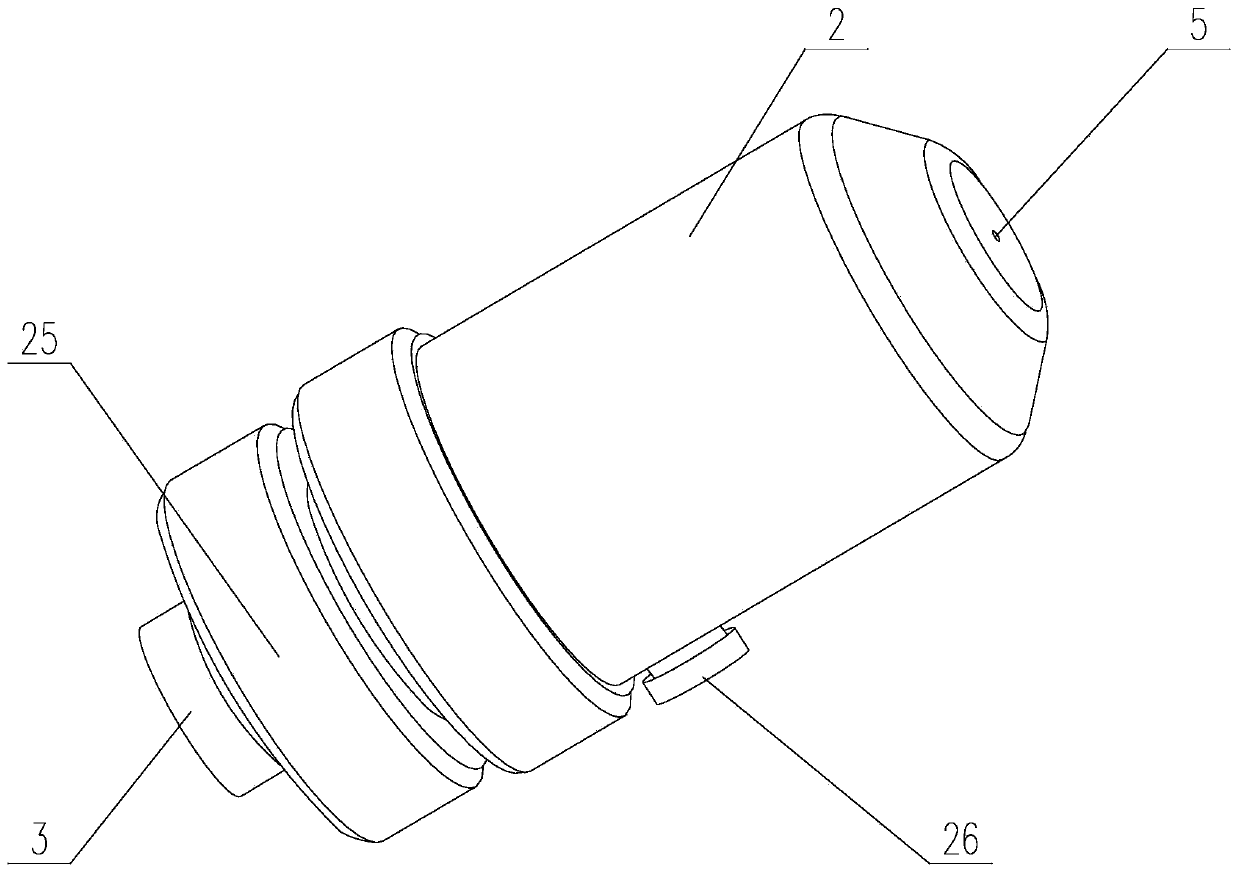

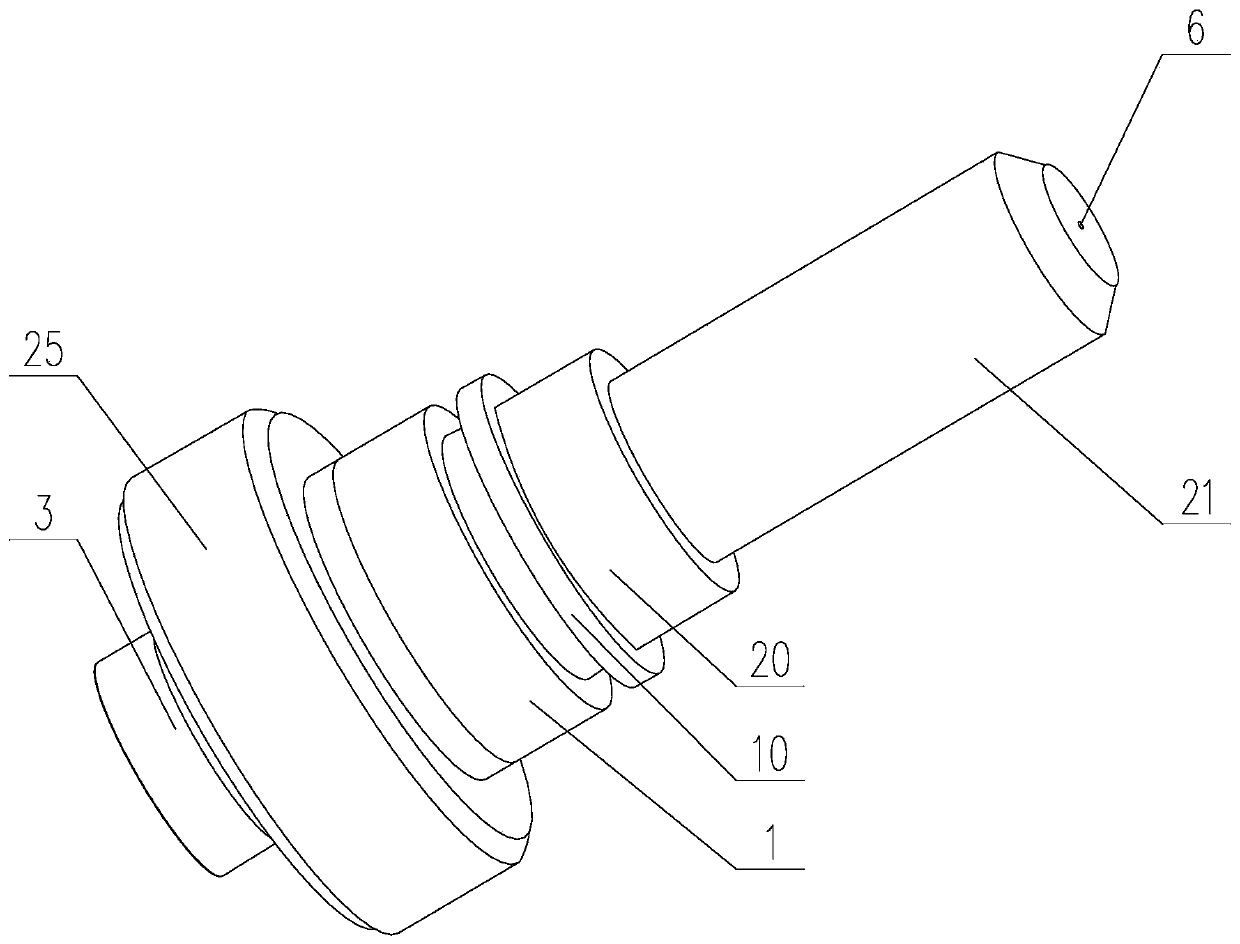

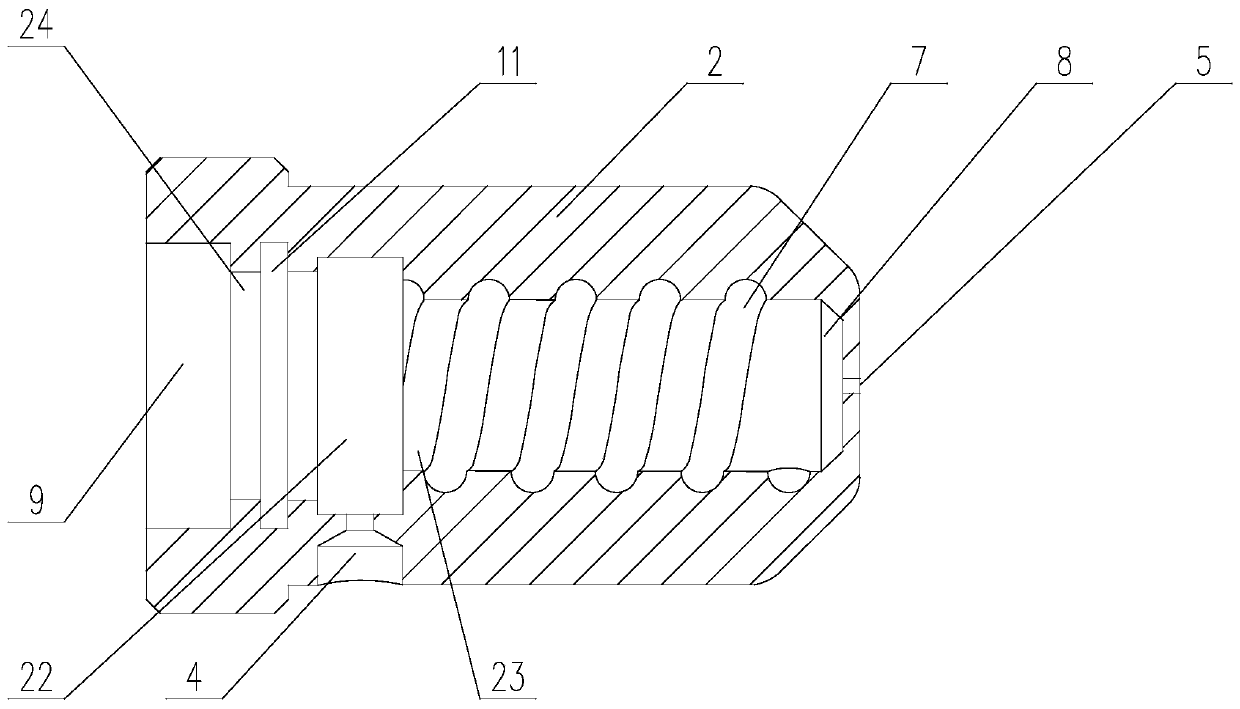

[0041] An atomizing spray head based on spiral air flow, the spray head includes a fixed column and a matching block 2;

[0042]The fixed column includes a limiting block 25, a connecting section 1, a load-bearing section 20 and a matching column 21 which are sequentially connected and coaxial and whose outer diameter decreases successively. The outer diameter of the fixing column decreases successively as it moves away from the limiting block 25 A water joint 3 is connected to the end of the fixing column away from the matching column 21, and a straight hole water channel 6 is provided on the side of the matching column 21 away from the bearing section 20, and the straight hole water channel 6 passes through the fixing column and communicates with the water joint 3 , a sealing ring 10 is sleeved on the bearing section 20, and a thread is provided on the side wall of the connecting section 1;

[0043] The fitting block 2 is a cylinder, and the fitting block 2 is provided with ...

Embodiment 2

[0048] A specific implementation description is made for the operation mode in Embodiment 1.

[0049] Such as figure 1 As shown, in the present invention, the nozzle will vibrate when it is working, and the thread will be continuously worn out, resulting in loosening of the connection between the matching block 2 and the fixed column. The side of the nozzle is provided with a fixing device. The movable plate 14 on the matching block 2 is inserted into the limiting plate 16 on the fixed column. Even if the thread has been worn to a certain extent, the matching block 2 will not rotate relative to the fixed column along the thread. So that the nozzle can always be fixed as a whole for use.

Embodiment 3

[0051] A specific implementation description is made for the operation mode in Embodiment 1.

[0052] Such as figure 1 As shown, in the present invention, anti-slip lines are provided on the surface of the limiting plate 16, which can increase the friction between the fingers and the limiting plate 16 when pulling the limiting plate 16, and prevent hands from being released during the pulling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com