Bending springback intelligent compensation device, continuous die and bending springback compensation method

A technology of compensation device and compensation method, which is applied in the direction of forming tools, metal processing equipment, metal processing, etc., can solve the problems of different springback, waste of human resources, and slow manual detection speed, so as to improve the degree of automation and production efficiency , high success rate, better plastic surgery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

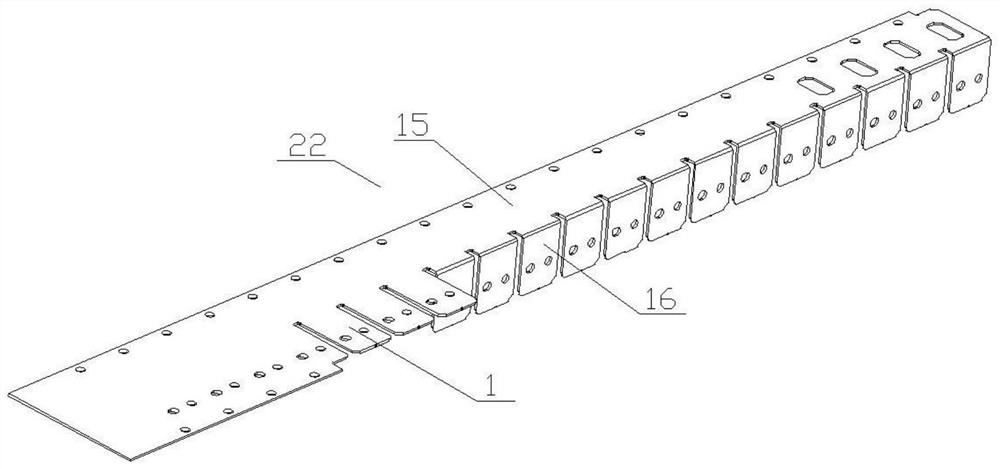

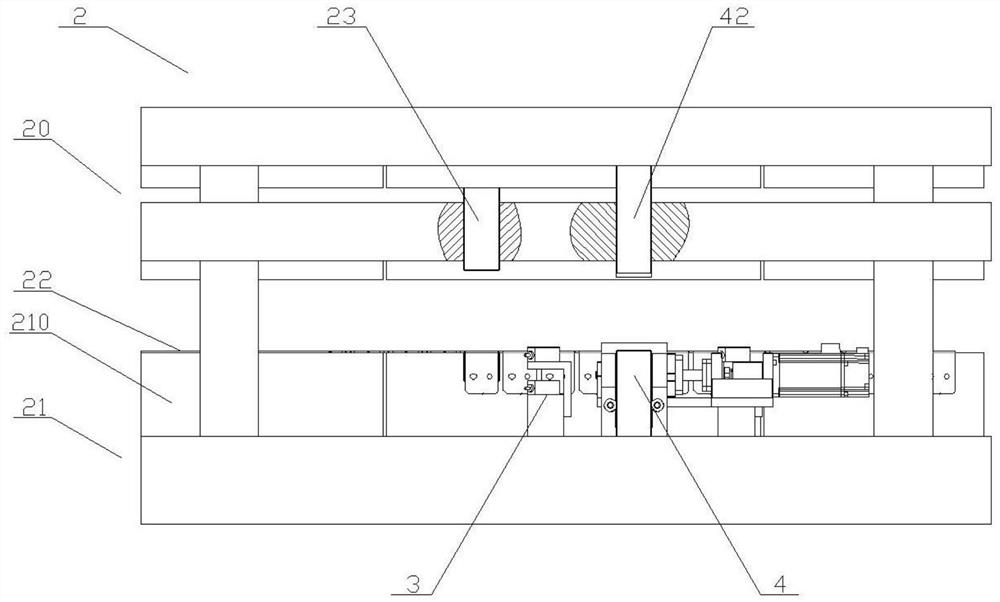

[0038] Such as image 3 As shown, the bending springback intelligent compensation device corresponding to a preferred embodiment of the present invention is installed on the continuous stamping die 2 for automatic detection and shaping of the stamped parts 1 after bending.

[0039] Such as image 3 As shown, the continuous mold 2 generally includes an upper mold assembly 20, a lower mold assembly 21 and a plurality of work stations. The material belt 22 can be driven by the feeding device (not shown) of the continuous mold 2 to move at equal intervals, so that the material belt 22 can pass through each station in turn. specific, image 3 The middle left end is the feed end of the material belt 22, and the right end is the discharge end of the material belt 22 after the continuous die processing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com