Decoration material cutting machine

A technology for cutting machines and cutting knives, which is applied in the direction of shearing devices, accessories of shearing machines, metal processing machinery parts, etc. It can solve the problems that affect the user's experience of using cutting machines for decoration materials, and achieve low noise and shock absorption effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

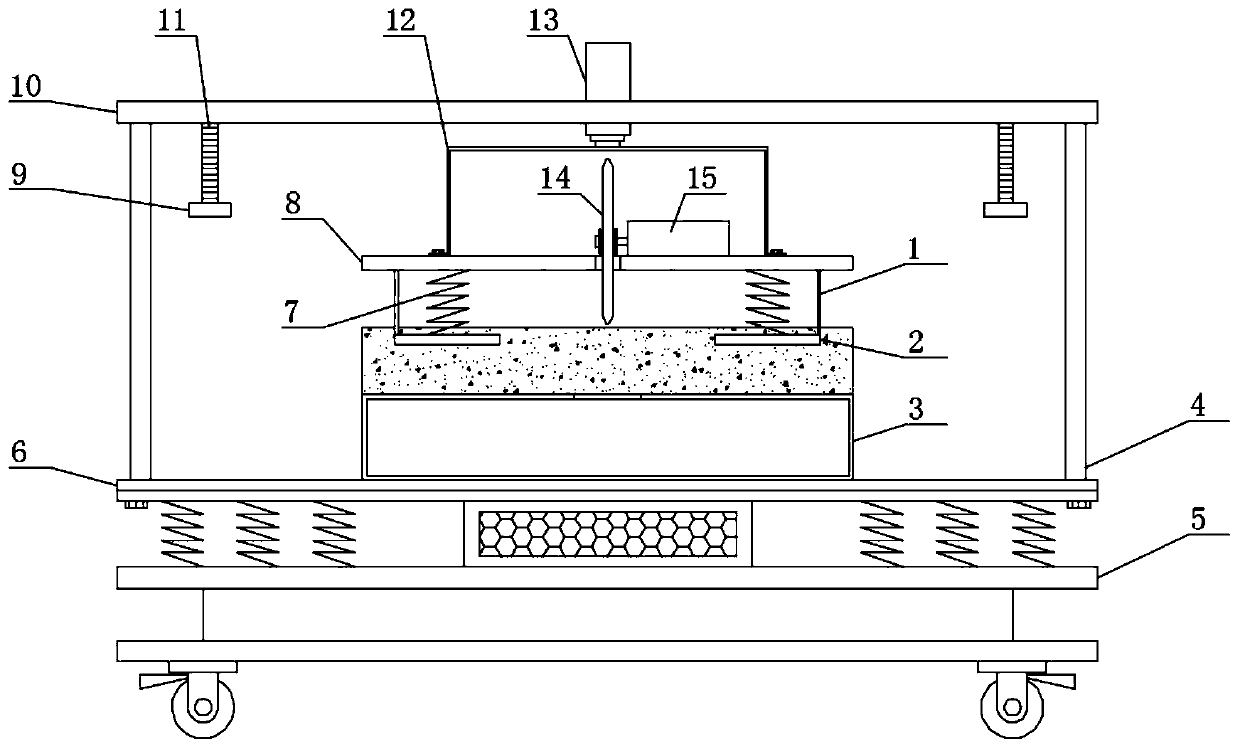

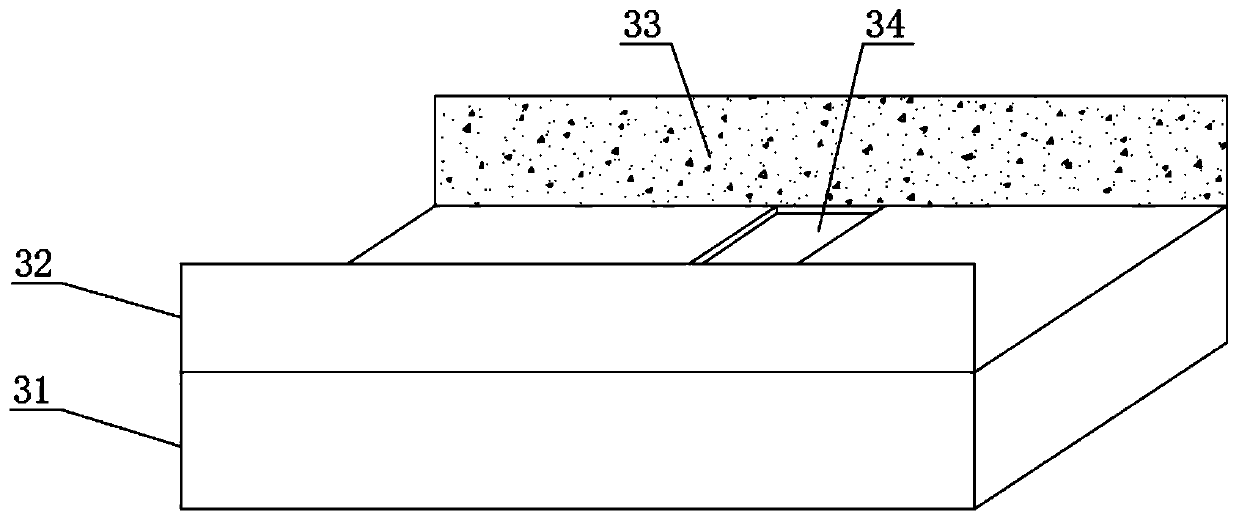

[0025] see Figure 1-Figure 3 , the present invention provides a technical solution: a cutting machine for decoration materials, including a support base plate 6, a support top plate 10 is arranged above the support base plate 6, a bracket 4 is provided at the connection between the support base plate 6 and the support top plate 10, and the support top plate 10 A hydraulic cylinder 13 is provided through the middle of the hydraulic cylinder 13, a first support plate 8 is provided below the hydraulic cylinder 13, a dust cover 12 is provided at the connection between the first support plate 8 and the hydraulic cylinder 13, and one end of the upper surface of the first support plate 8 Drive motor 15 is provided, and the output end of drive motor 15 is provided with cutting knife 14, and the upper surface of support base plate 6 is provided with dust removal mechanism 3, and dust removal mechanism 3 comprises dust removal box 31, and the middle position of the upper surface of dust...

Embodiment 2

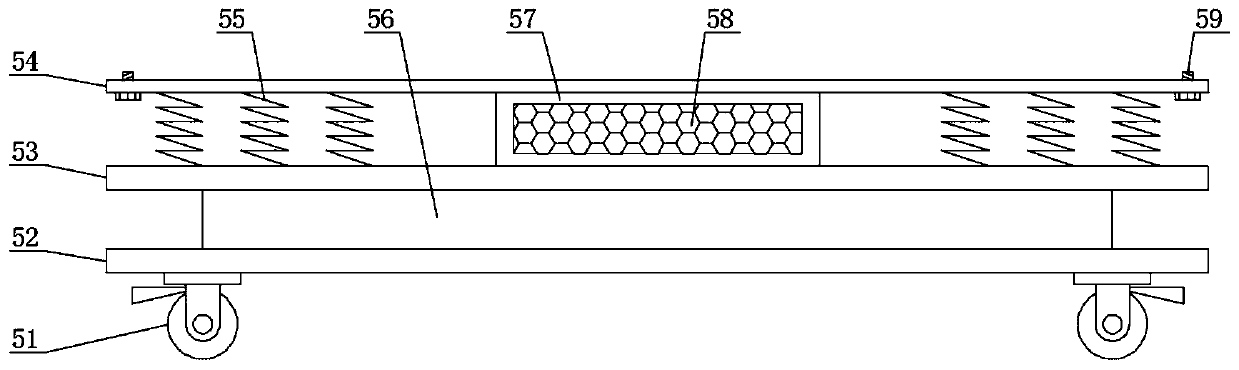

[0031] see Figure 1-Figure 3 , on the basis of Embodiment 1, in order to make the shock absorption effect of the decoration material cutting machine better, in this implementation, preferably, a shock absorption mechanism 5 is arranged below the support base plate 6, and the shock absorption mechanism 5 includes a third support plate 53, a fourth support plate 54 is arranged on the top of the third support plate 53, and the fourth support plate 54 is fixed on the support base plate 6 through the screws 59 at both ends of the lower surface. The connection between the third support plate 53 and the fourth support plate 54 A shock-absorbing plate 57 is provided, and the shock-absorbing plate 57 converts the received kinetic energy into its own elastic potential energy, thereby playing a shock-absorbing role;

[0032] In order to make the cost of the shock absorbing plate 57 lower, in this implementation, preferably, the material of the shock absorbing plate 57 is rubber, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com