Transferable prepreg thin-shell mold, mold system and application method thereof

A technology of prepreg and mold, which is applied in the field of compression molding of composite materials, can solve problems such as unsafe production efficiency, and achieve the effect of improving safety and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

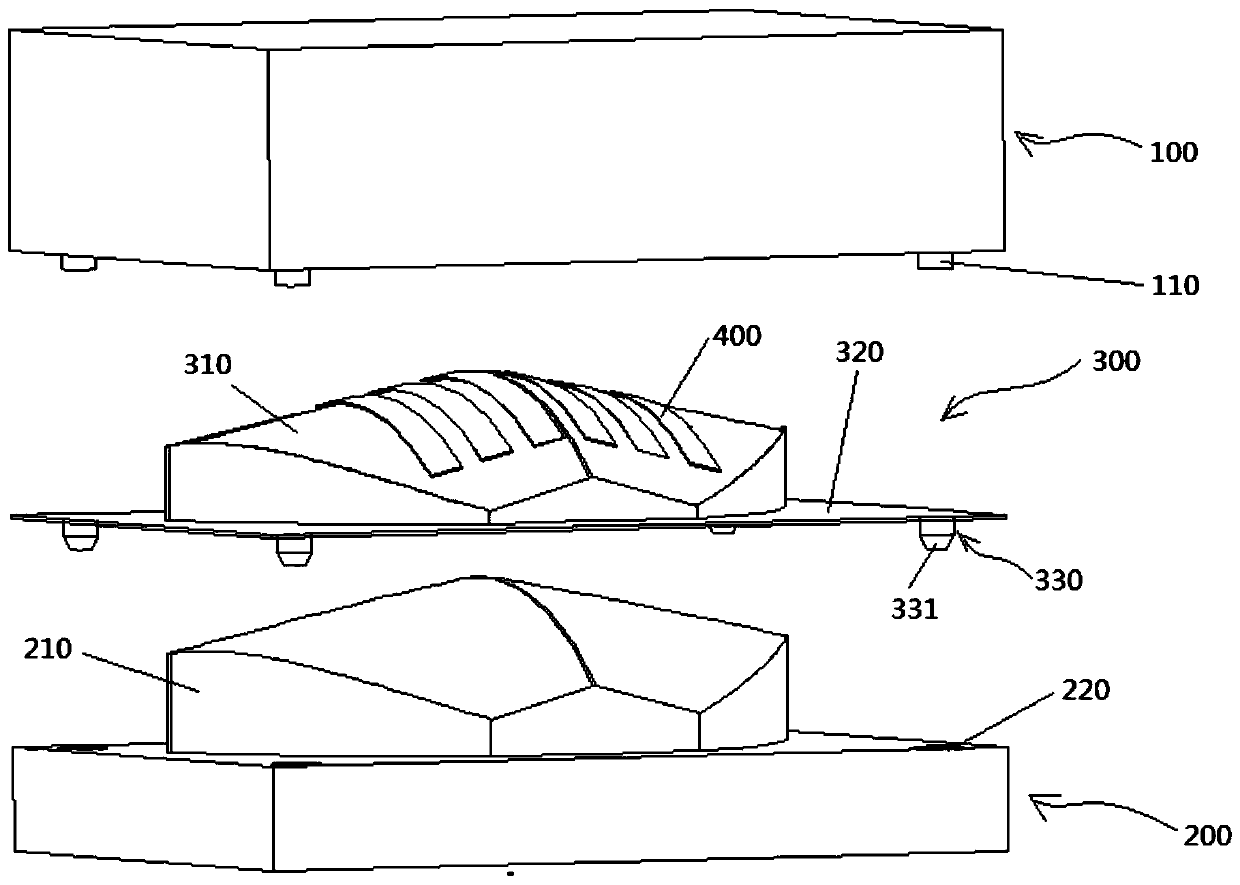

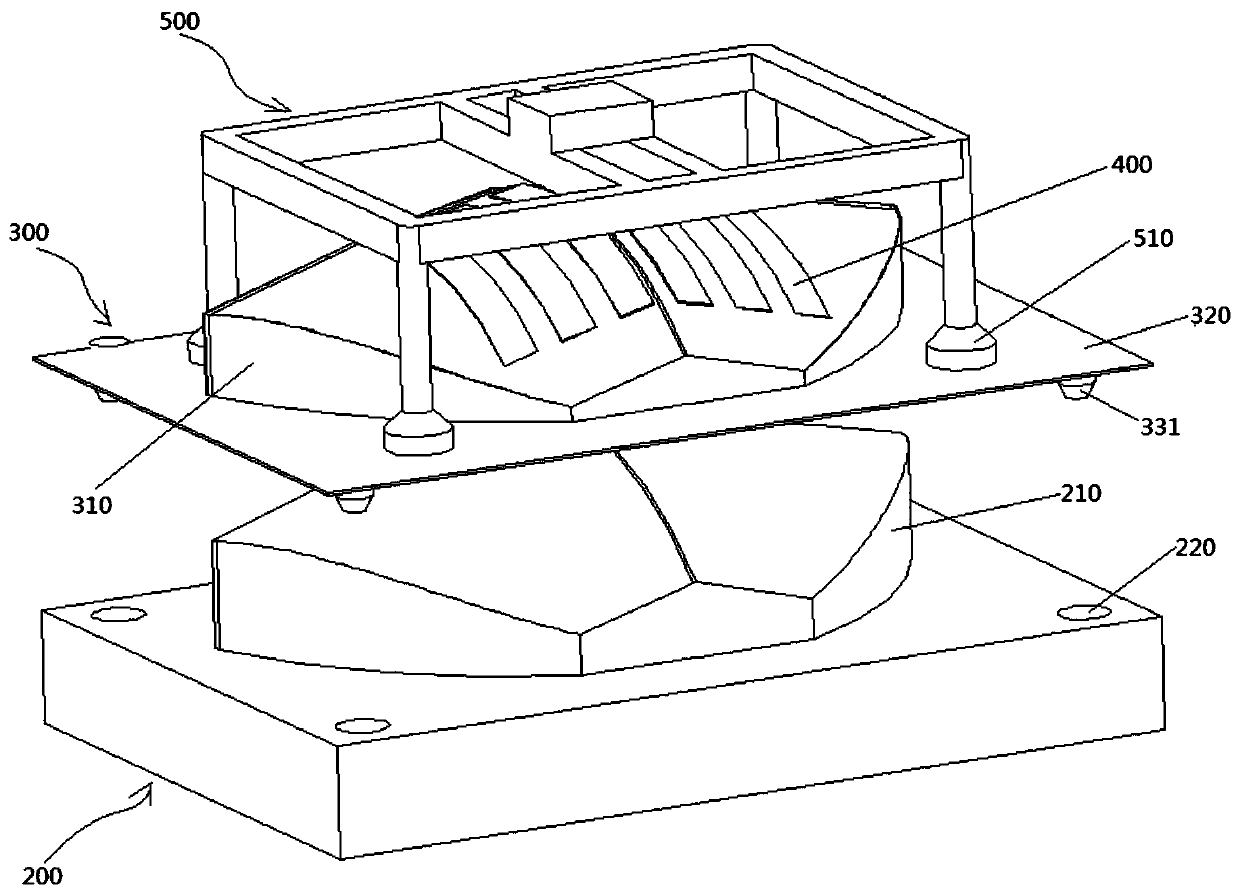

[0027] The following is attached Figure 1-3 , to further illustrate the transferable prepreg thin shell mold tire, prepreg transfer mold system and using method of the present invention.

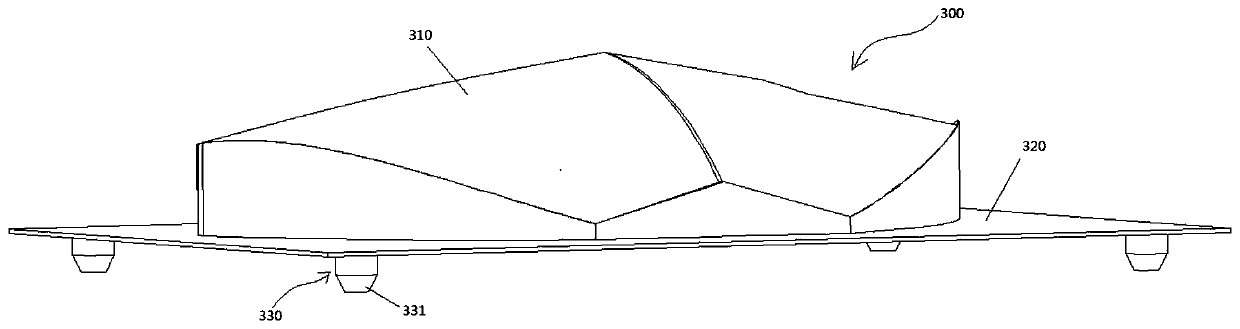

[0028] Such as figure 1 As shown, a transferable prepreg thin shell mold tire 300 of the present invention, its upper surface has mold tire protrusions 310 that match the depression of the upper mold 100, and its lower surface has lower mold protrusions that match the lower mold. 210, so that the transferable prepreg thin shell mold tire 300 can be completely attached to the depression of the upper mold 100 and the lower mold protrusion 210 of the lower mold.

[0029] The lower part of the transferable prepreg thin shell mold tire 300 is provided with a transfer plane 320 , and the corners of the transfer plane 320 are provided with positioning pins 330 , generally a plurality of positioning pins 330 are arranged evenly near the edge of the transfer plane 320 .

[0030] In order to enabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com