Rapid manufacturing method and manufacturing assisting system of composite structural slab

A technology of composite materials and manufacturing methods, applied in lamination auxiliary operations, chemical instruments and methods, image data processing, etc., can solve problems such as difficult product inspection, low production efficiency, and high labor intensity, and avoid manual measurement and marking , improve efficiency and accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

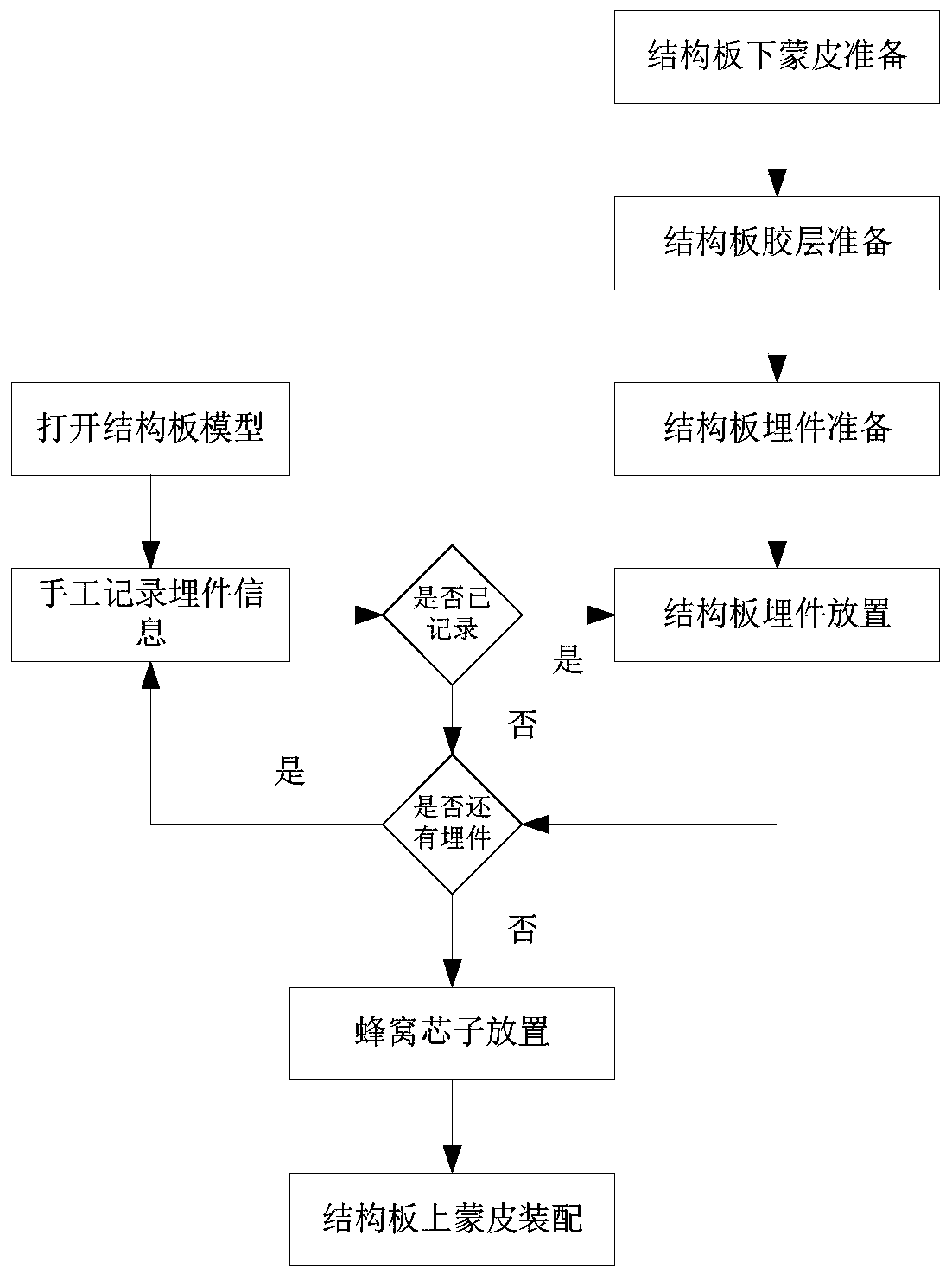

[0039] The present invention will be described in detail below with reference to the drawings and embodiments.

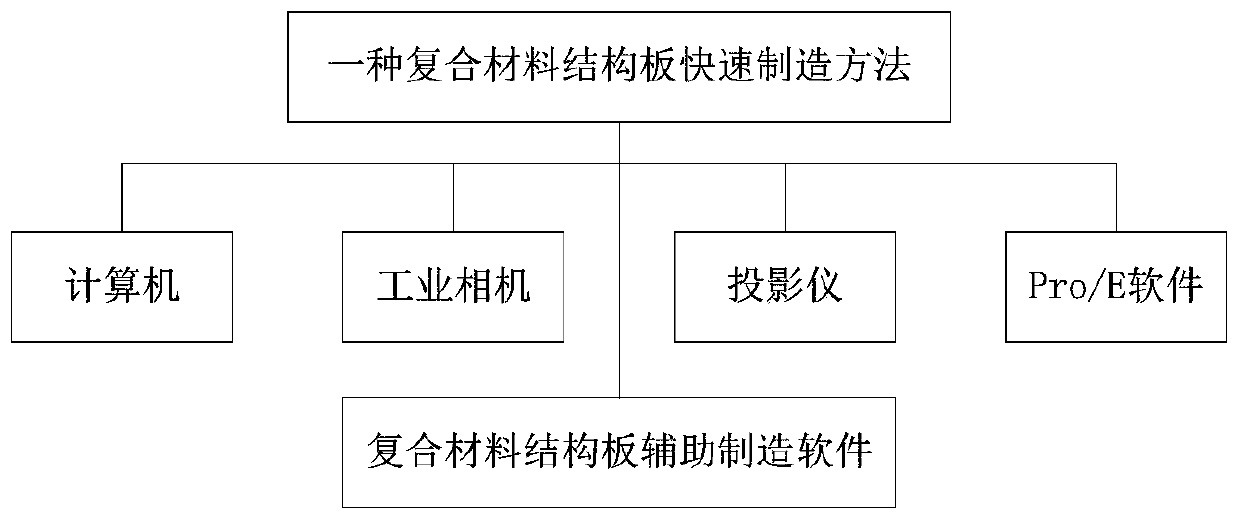

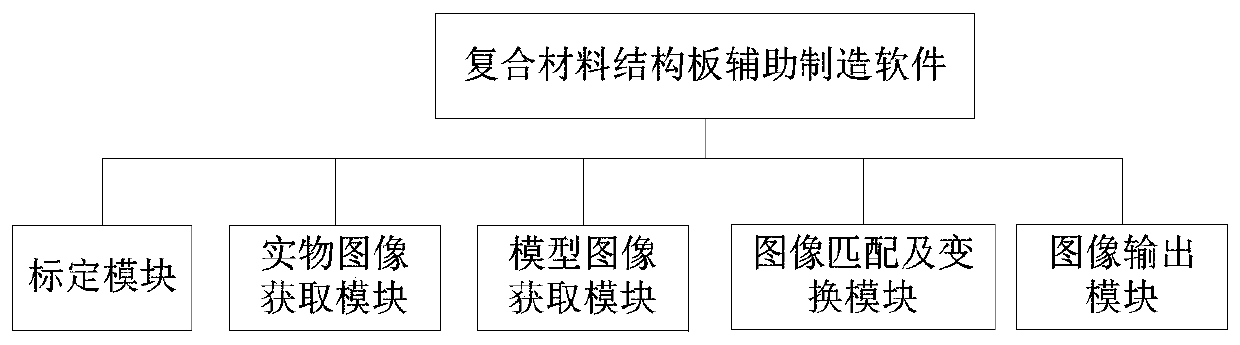

[0040] This embodiment provides a rapid manufacturing method for composite material structural panels, such as figure 2 As shown, hardware and software are used. The hardware includes a computer, a calibration board, an industrial camera and a projector, and the main body of the software uses Pro / E.

[0041] The computer on the production site is used for the display, software operation and hardware connection of the composite material structural plate model, and is equipped with Pro / E secondary development composite material structural plate auxiliary manufacturing software, and is connected with industrial cameras and projectors.

[0042] The industrial camera is used to obtain the physical image information of the skin and the target under the structural plate on the field workbench, and use image recognition to process the physical image.

[0043] The projector is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com