Fireproof glass tempering furnace

A glass tempering and tempering furnace technology, which is used in glass tempering, glass manufacturing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

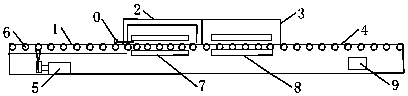

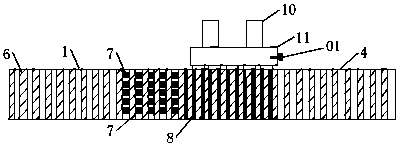

[0020] There is an upper section 1 on the front side of the tempering furnace, a lower section 4 on the rear, and a heating section 2 and a tempering section 3 between the upper section and the lower section;

[0021] A transmission roller 6 is installed on the tempering furnace body, and the driving wheel of the transmission roller is connected with the driving motor 5 wheels arranged at the lower part through a belt, and serves as the driving force for glass operation;

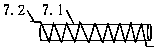

[0022] In the heating box of the heating section, a heater 7 spaced up and down is installed. The heater is composed of a matrix of electric heating wires 7.2 wound on ceramic tubes 7.1. A temperature sensor 0 is installed in each ceramic tube, and the ceramic tubes are arranged in the forward direction. , through the heating module to control the glass heating temperature at 650-1000°C;

[0023] In the toughening section, there are two layers of air grids 8 at intervals above and below. The air grids are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com