A thermo-induced phase change thermal control skin based on near-field thermal radiation and its application in spacecraft

A thermally induced phase change and thermal radiation technology, applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve thermally induced phase change material deposition, performance degradation, small emissivity adjustment range problem, to achieve the effect of no moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

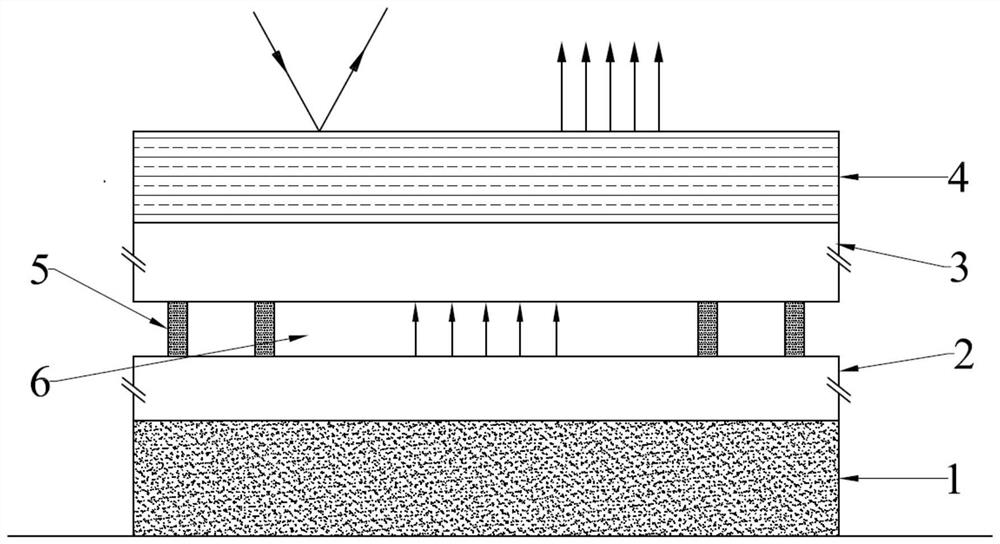

[0058] A kind of heat-induced phase change thermal control skin, including base 1, inner layer film system 2, outer layer film system 3 and optical solar reflector 4 from bottom to top, and between inner layer film system 2 and outer layer film system 3 has The spacer 5, the spacer 5 forms a vacuum gap 6 with a pitch of micronano scale between the inner layer film system 2 and the outer layer film system 3, and the inner layer film system 2 contains a thermally induced phase change Thermally induced phase change film layer composed of materials.

[0059] Specifically, the material of substrate 1 is SiO 2 , the inner film system 2 is single-layer VO 2 The thin film, with a film thickness of 200nm, is coated by magnetron sputtering. The CMO-based OSR produced by the British Point-source company is selected as the optical solar reflector 4, its infrared emissivity ε = 0.87, and the solar spectral absorptivity α s =0.085, the outermost layer of the selected optical solar reflec...

Embodiment 2

[0062] A kind of heat-induced phase change thermal control skin, including base 1, inner layer film system 2, outer layer film system 3 and optical solar reflector 4 from bottom to top, and between inner layer film system 2 and outer layer film system 3 has The spacer 5, the spacer 5 forms a vacuum gap 6 with a pitch of micronano scale between the inner layer film system 2 and the outer layer film system 3, and the inner layer film system 2 contains a thermally induced phase change Thermally induced phase change film layer composed of materials.

[0063] Specifically, the material of substrate 1 is SiO 2 , the inner film system 2 is single-layer VO 2 Thin film, with a film thickness of 100nm, is coated by magnetron sputtering. The CMO-based OSR produced by the British Point-source company is selected as the optical solar reflector 4, its infrared emissivity ε = 0.87, and the solar spectral absorptivity α s = 0.085. Plating a layer of silver (Ag) base film and a layer of in...

Embodiment 3

[0066] A kind of heat-induced phase change thermal control skin, including base 1, inner layer film system 2, outer layer film system 3 and optical solar reflector 4 from bottom to top, and between inner layer film system 2 and outer layer film system 3 has The spacer 5, the spacer 5 forms a vacuum gap 6 with a pitch of micronano scale between the inner layer film system 2 and the outer layer film system 3, and the inner layer film system 2 contains a thermally induced phase change Thermally induced phase change film layer composed of materials.

[0067] Specifically, the material of the substrate 1 is SiC, and the inner film system 2 includes an inner layer of VO 2 film and an outer layer of SiC film, where VO 2 The film thickness of the film is 100 nm, the film thickness of the SiC film is 20 nm, and the film is deposited by magnetron sputtering. The CMO-based OSR produced by the British Point-source company is selected as the optical solar reflector 4, its infrared emissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com