Steam pulse type audio frequency dust removing device and dust removing method

A cleaning device and pulse-type technology, applied in cleaning methods and appliances, combustion methods, chemical instruments and methods, etc., can solve the inconvenience of increasing the speed and impact of steam, inconvenient auxiliary support, and lack of storage, etc. Problems, to achieve the effect of increasing cleaning, increasing functionality, reasonable installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

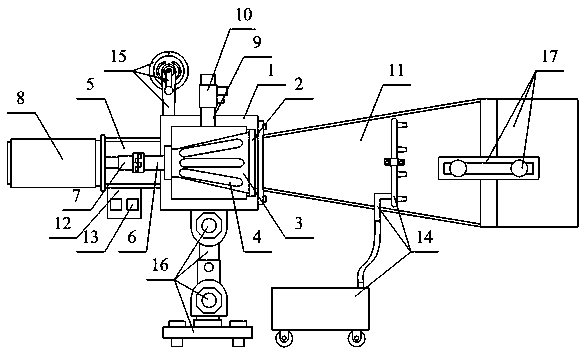

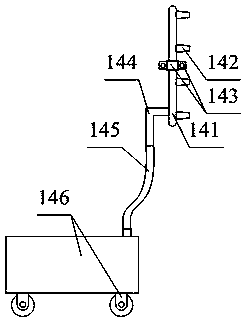

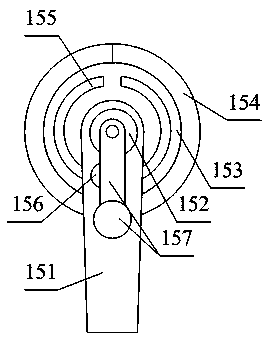

[0045] as attached figure 1 to attach figure 2 As shown, a steam pulse type audio frequency cleaning device includes a working box 1, a first auxiliary bearing 2, a rotating head 3, an inlet and outlet hole 4, a connecting cylinder 5, a rotating shaft 6, a coupling 7, a rotating motor 8, and Steam head 9, quick exhaust valve 10, exhaust head 11, PLC12, switch 13, auxiliary inflation pipe frame structure 14, auxiliary pipeline storage cylinder structure 15, installation of rotating seat structure 16 and adjustment of steam outlet structure 17, the described The first auxiliary bearings 2 are respectively inlaid on the left and right sides of the inside of the working box 1, and the rotating head 3 is inserted into the inside; the inlet and outlet holes 4 are respectively provided on the outer wall of the rotating head 3; the connecting cylinder 5 is welded At the left end of the working box 1; one end of the rotating shaft 6 is welded to the left end of the rotating head 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com