Heater support device

A technology of supporting device and heater, which is applied to furnace heating elements, gaseous chemical plating, metal material coating process, etc., can solve the problems of heat absorption and heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

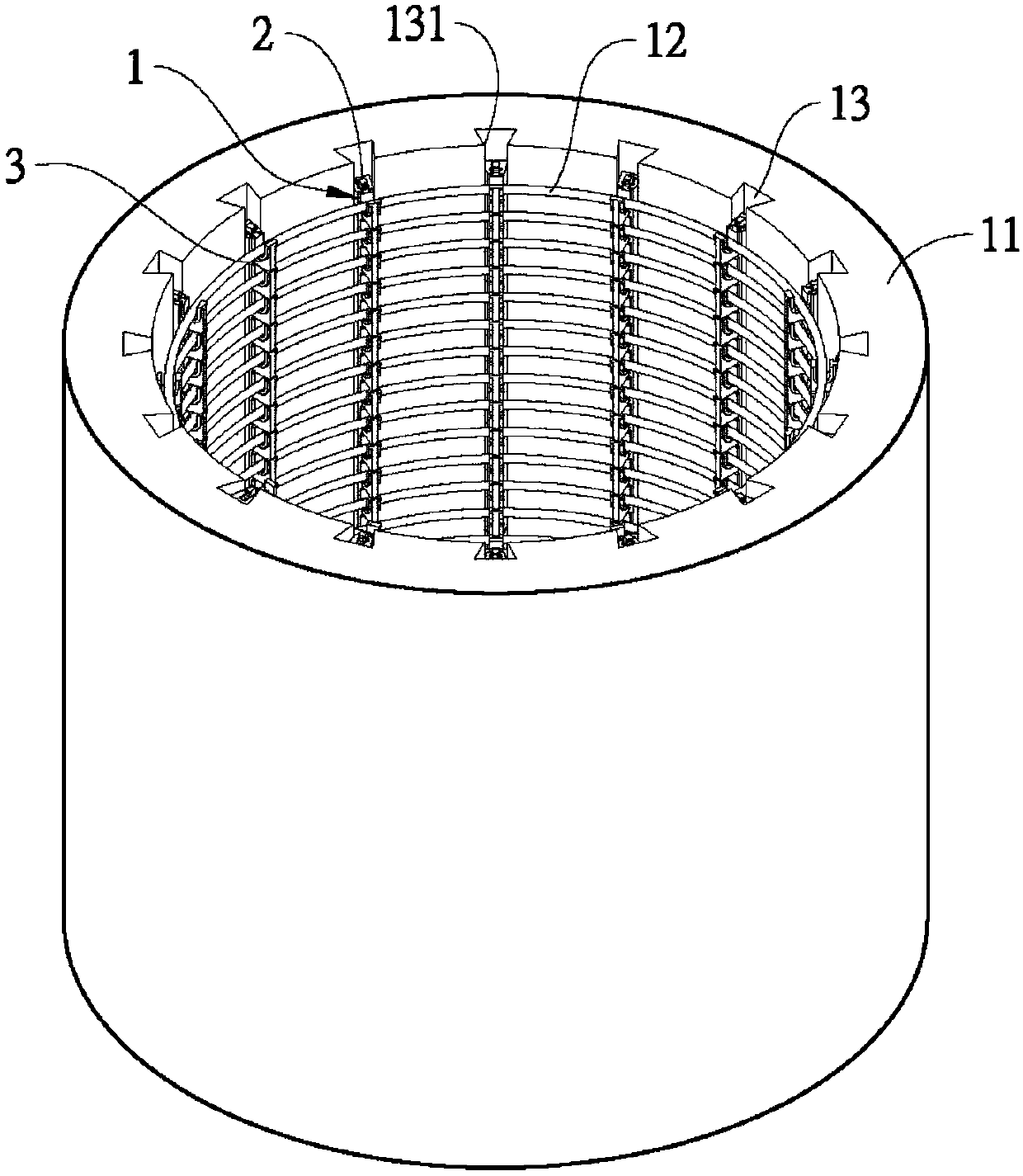

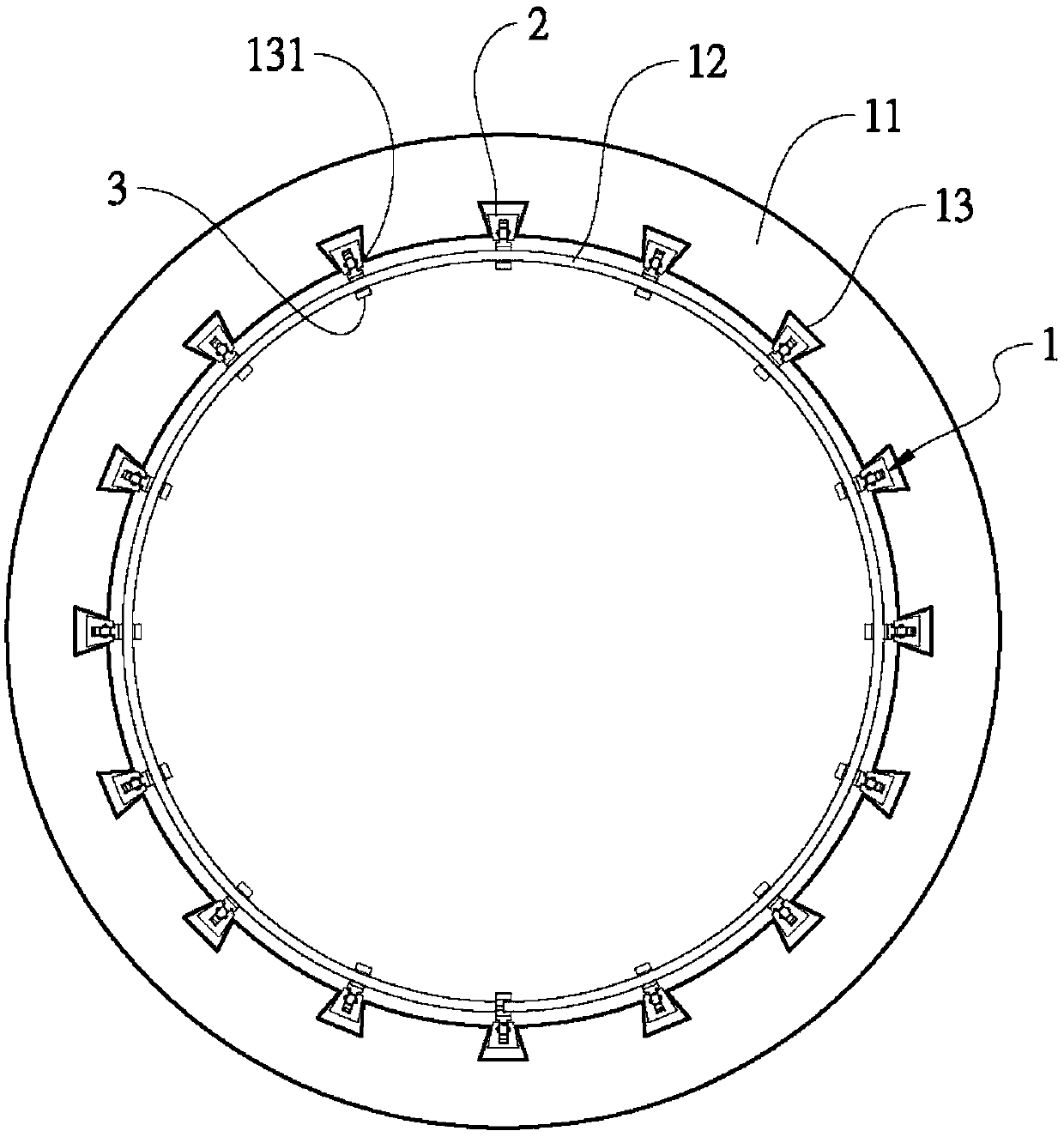

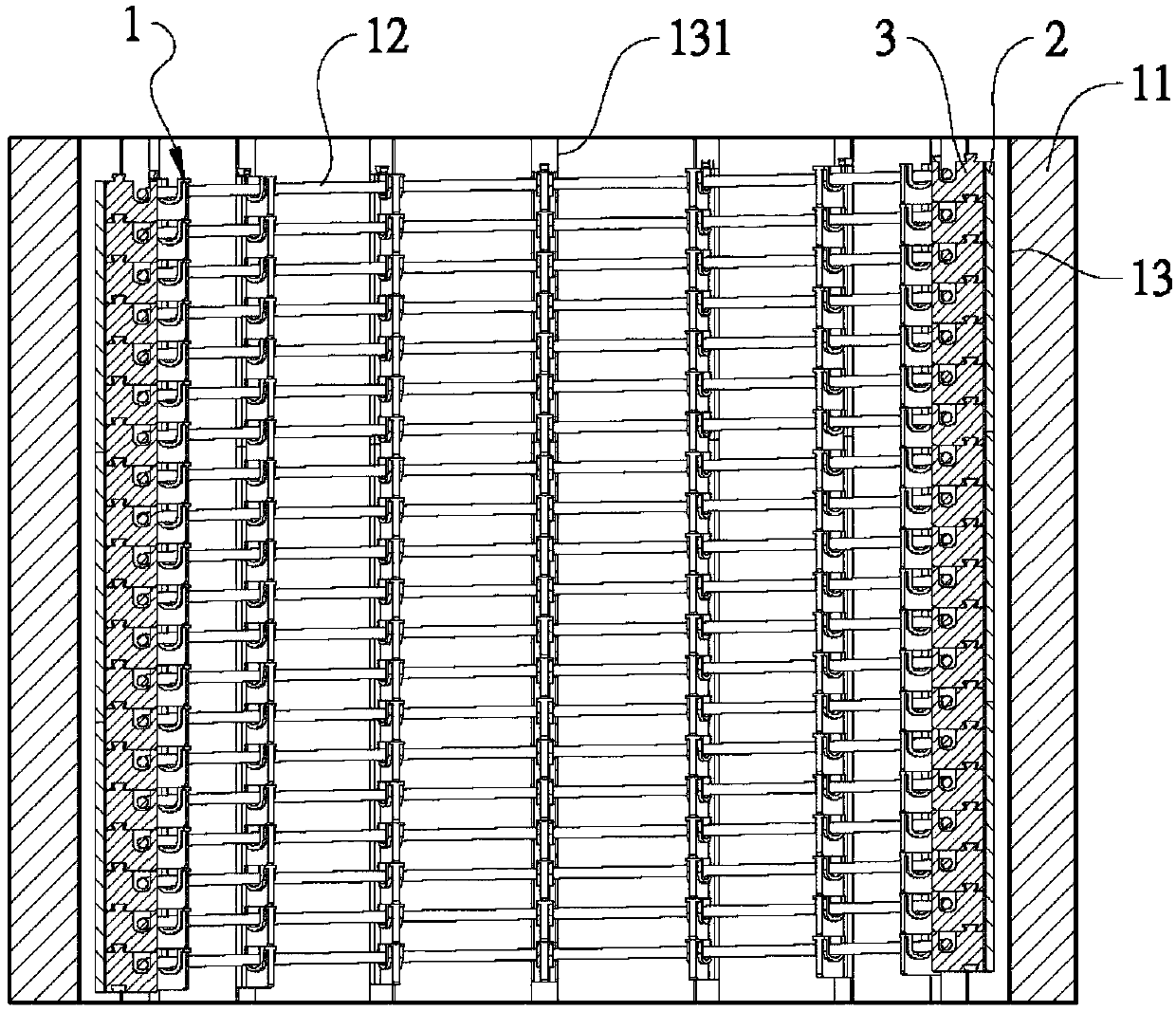

[0036] see Figure 1~3 As shown, the heater supporting device 1 of the present invention is installed on the inner periphery of a surrounding heat insulator 11 in a vertical furnace for supporting a coil-type heating element 12 coaxial with the surrounding heat insulator 11 . The above-mentioned vertical furnace can be used for a plurality of semiconductor manufacturing processes such as diffusion and chemical vapor deposition (CVD), and the vertical furnace can heat the reaction gas inside the furnace through the above-mentioned process to make multiple wafers, etc. A thin film is formed on the surface of the substrate. The surrounding heat insulator 11 is in the shape of a circular tube, and its inner periphery is provided with a plurality of axial and spaced elongated axial grooves. The peripheral edge is radially depressed, and the cross-section of the groove is a tapered trapezoid, and its opening position has a limiting portion 131 whose width is smaller than the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com